Cylindrical Vertical Grading Mill

A pulverizer and cylindrical technology, applied in the field of vertical grading pulverizers, can solve the problems of poor pulverization effect and restrict the spatial distribution of hammers and knives, and achieve the effects of improving pulverizing effect, increasing space height and reducing stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

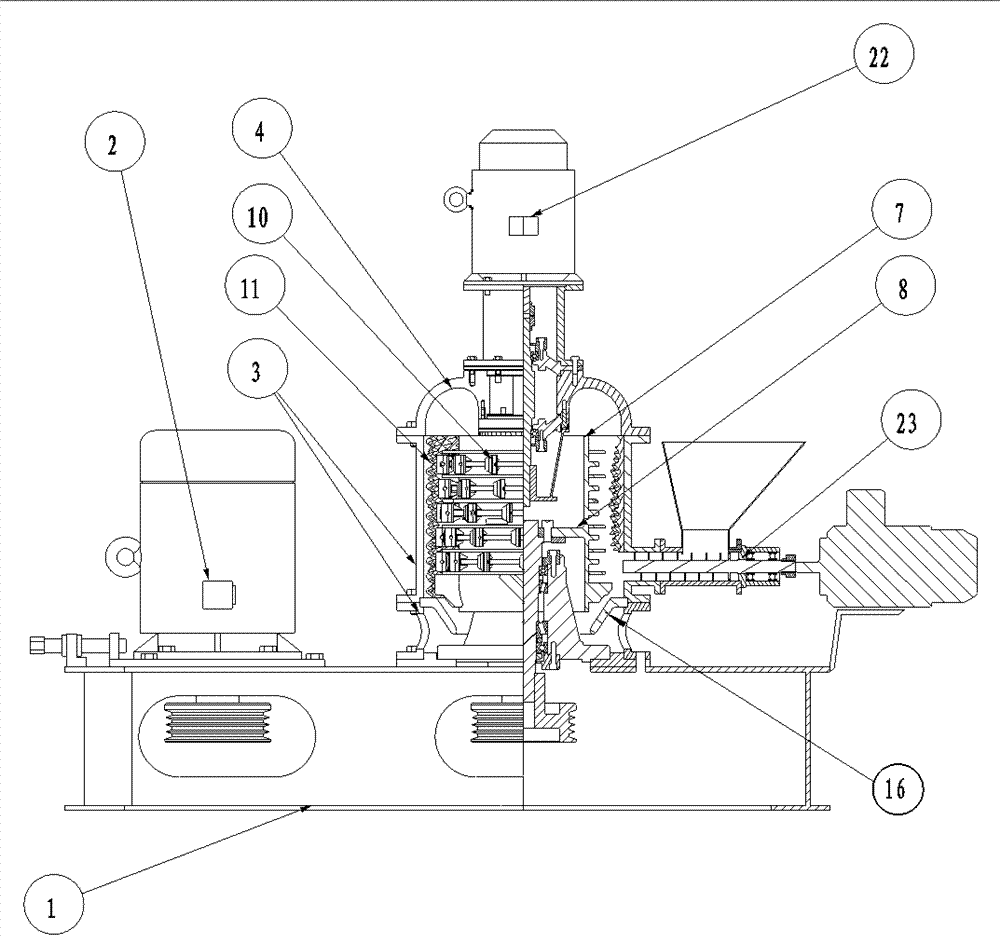

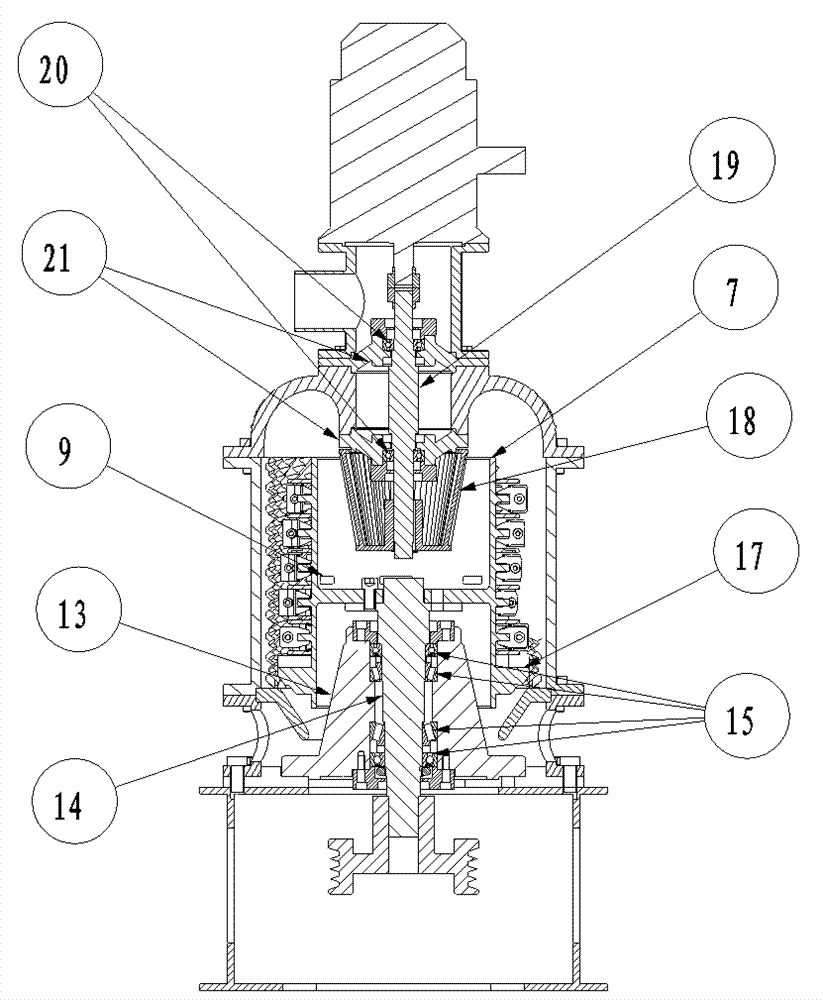

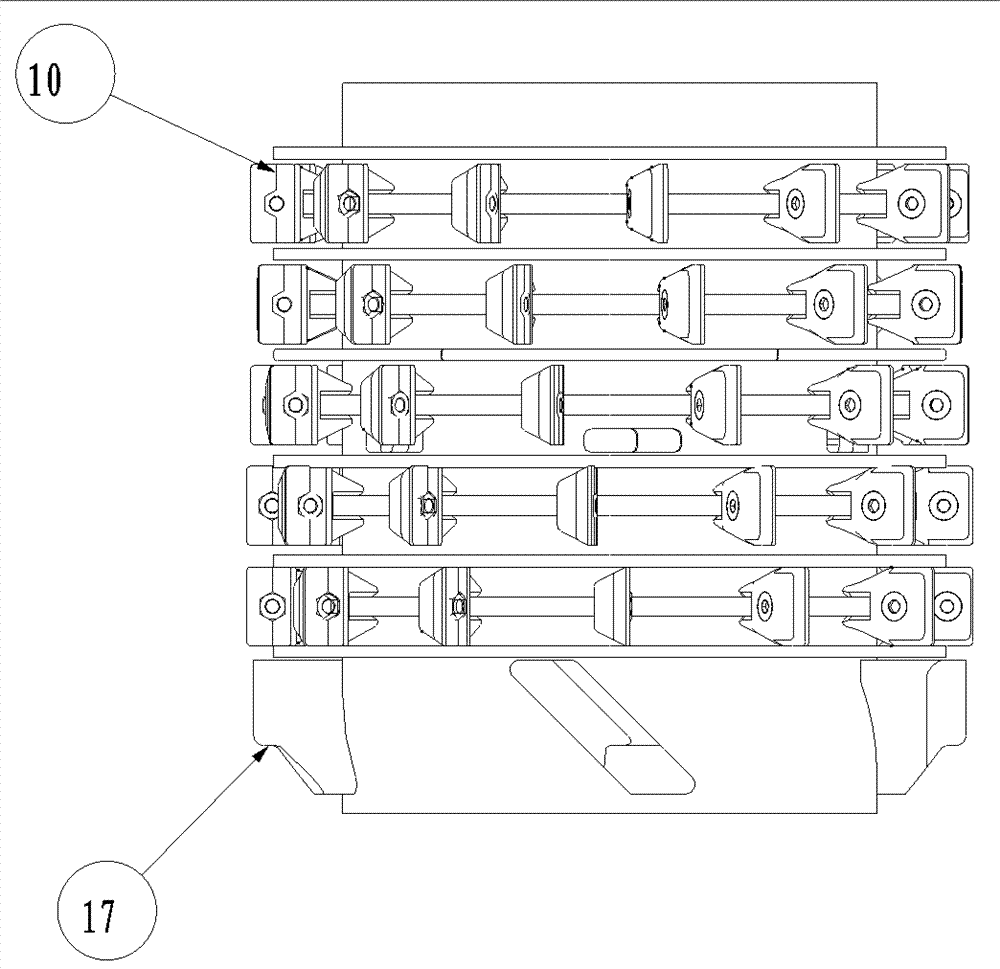

[0014] figure 1 , figure 2 In the shown embodiment, the crushing cylinder (7) is connected to the partition (8) by welding, and there are positioning holes and bolt holes on the connecting partition (8) to connect with the main shaft (14), and the main shaft is equipped with two pairs of upper and lower main shaft bearings (15), the bearing is fixedly installed in the tapered bearing seat (13) fixedly connected with the frame (1); the dredging vane (17) is welded and fixed on the lower outer surface of the crushing drum hammer knife. The grading wheel (18) is installed on the grading wheel shaft (19), and is fixedly connected with the casing cover (4) through the grading bearing (20), the grading bearing seat (21), and the top of the grading wheel shaft (19) is connected to the grading motor through a coupling. (22) CONNECTED.

[0015] The air enters the lower part of the casing (3), passes through the conical sleeve (16), passes through the dredging vane (17), meets the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com