A kind of anti-pull diagonal bracing structure for high pier used for foundation pit support

A pier pull-back type and foundation pit support technology, which is applied in the direction of basic structure engineering, construction, excavation, etc., can solve the problems of high cost, difficulty in earthwork excavation, difficulty in main structure construction, etc., and achieves easy excavation and easy construction of the main structure , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

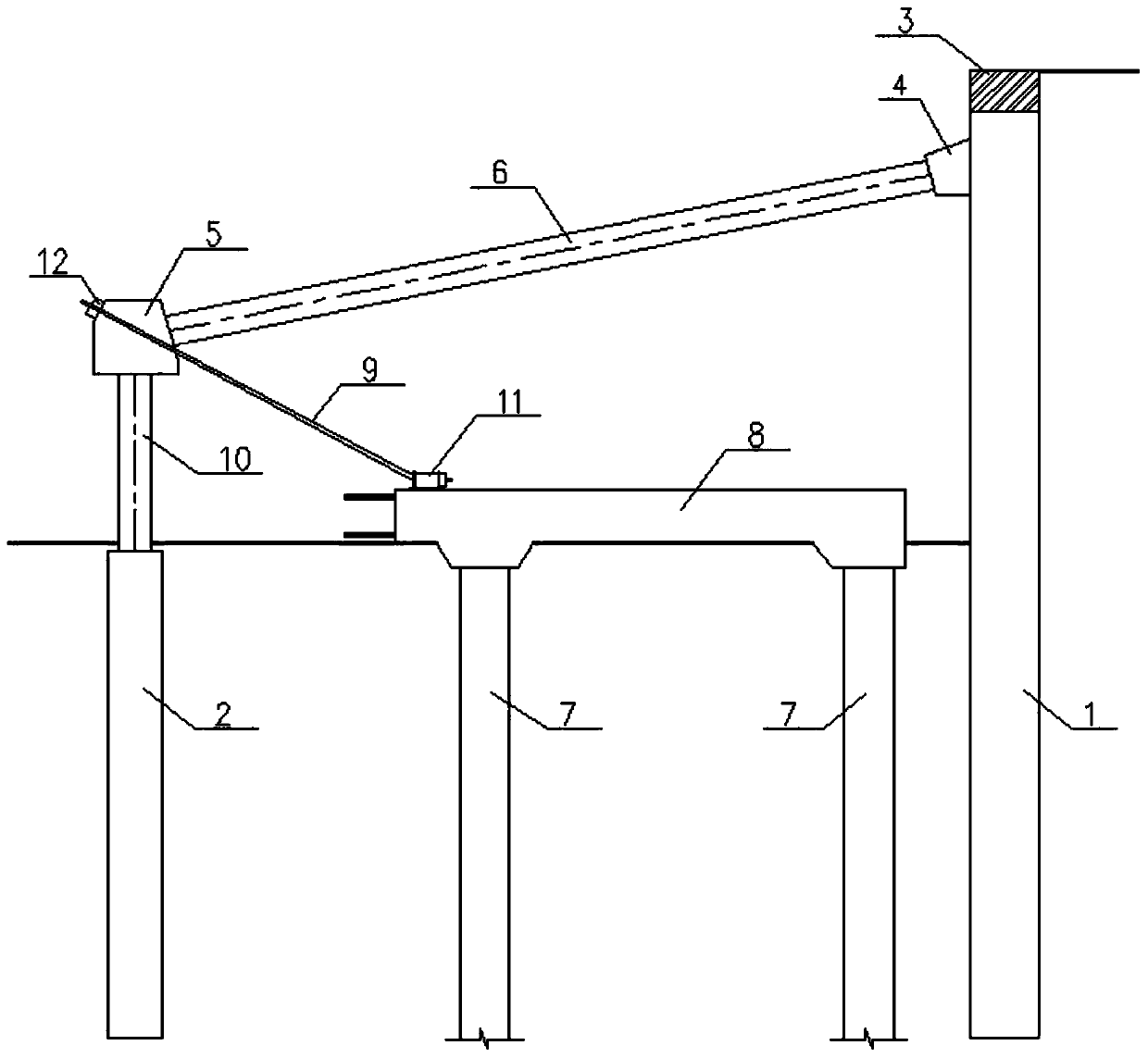

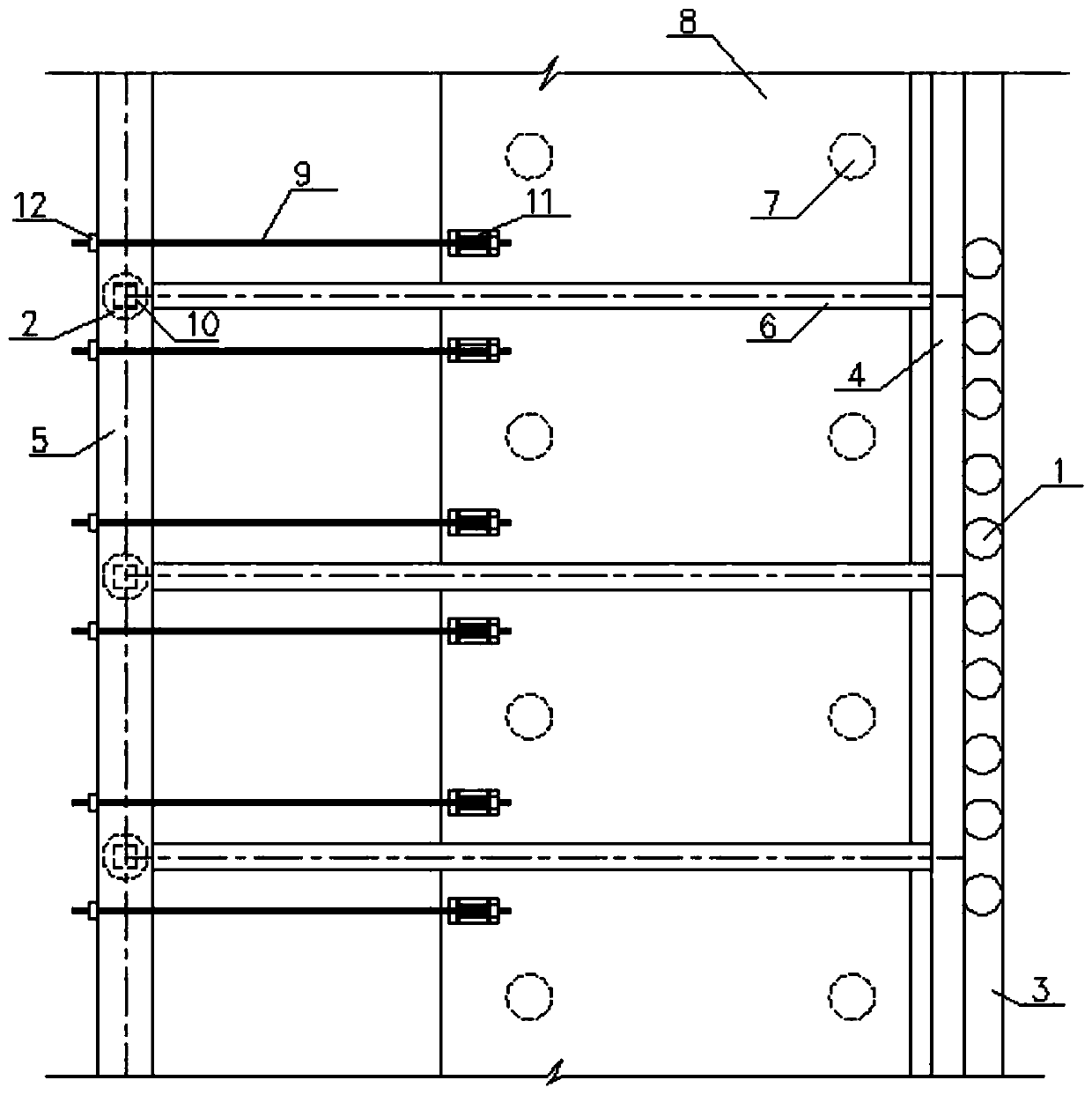

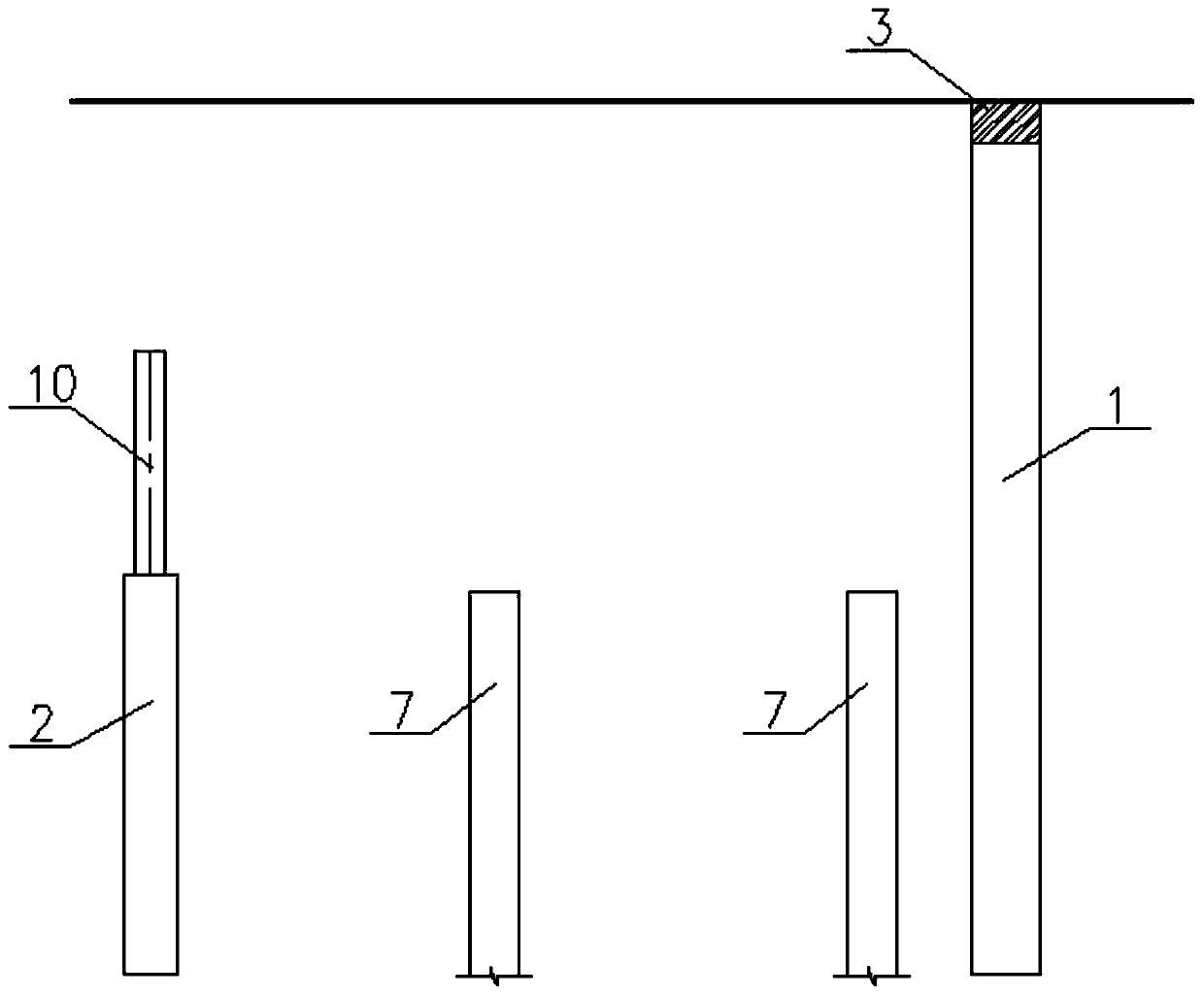

[0032] see image 3 , first set the parameters of enclosure structure 1, buttress pile column 2, and two rows of pile foundation columns 7 according to the specific parameters of the foundation pit, and pre-set the parameters of enclosure structure 1, buttress pile column 2 and two rows of pile foundation columns 7 It is poured into shape, and the enclosure structure 1, the pier column 2, and the two rows of pile foundation columns 7 are arranged parallel to each other; the enclosure structure 1 adopts the method of row piles, and each row of piles is parallel to each other, and the height of the top of the row pile is higher than The height of the top of the foundation pit, so as to be fixedly connected with the crown beam 3; the buttress pile column 2 is formed by a plurality of buttress piles parallel to each other; method; the top of the pier pile and the top of the foundation pile are all arranged at the bottom of the foundation pit; the steel column 10 is constructed on ...

no. 2 example

[0039] The main structure to be built in the foundation pit in this example is the first floor underground, the excavation depth of the foundation pit is 6m, and the plane span is 150m. The surrounding environment is complex, and the deformation control of the foundation pit is strictly required. The internal support adopts the diagonal support in the pit.

[0040] The enclosure structure 1 is specifically composed of a plurality of rows of piles, see figure 2 . The row of piles adopts 900mm diameter bored piles, the piles are 12m long, and form columns at a certain distance. The pile foundation of the main structure adopts 800mm diameter bored piles, and the pile top elevation is 100mm above the bottom of the proposed basement floor structure. The buttress pile column 2 is specifically composed of multiple buttress piles in a row. The buttress piles are 900mm diameter bored piles. The pile top elevation is 200mm below the bottom of the basement floor cushion to be built. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com