Sparking plug and press fitting method

A spark plug, press-fitting technology, applied in spark plugs, spark plug manufacturing, electrical components, etc., can solve the problems of limiting the EMC performance of spark plugs, reducing space, and complex process, and achieving the effect of improving EMC performance, increasing space height, and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

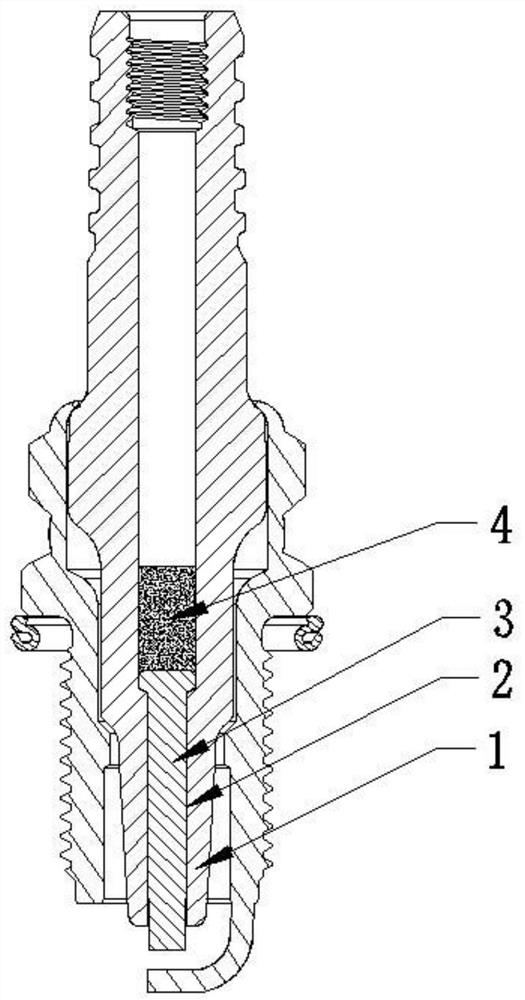

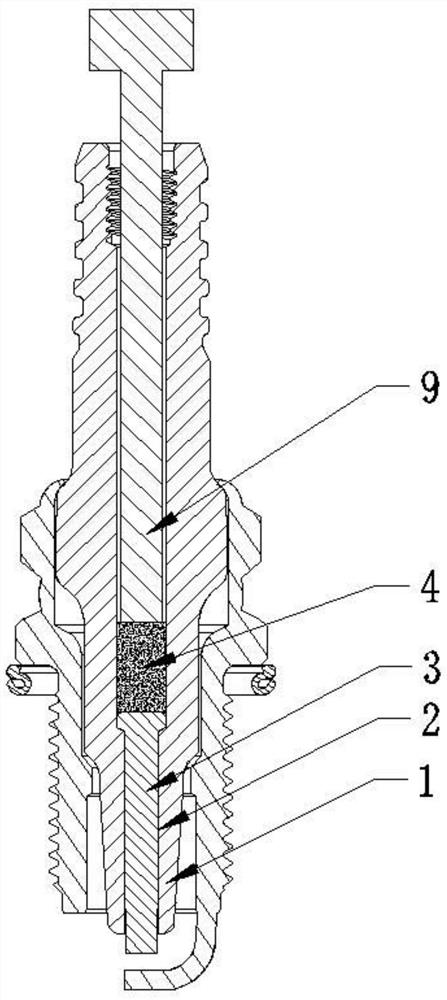

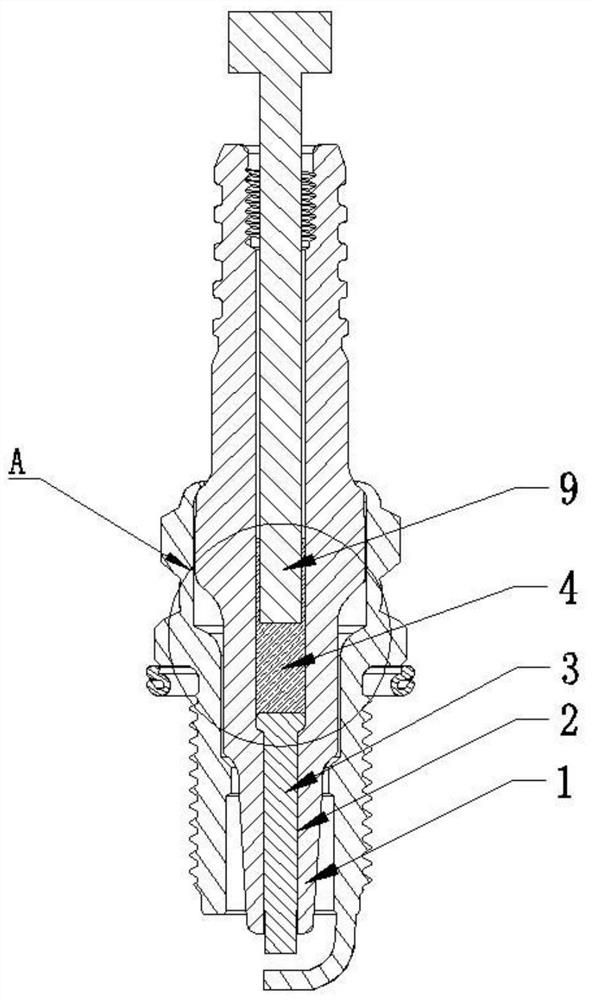

[0052] Existing spark plug high-temperature press-fitting process such as Figures 1 to 4 As shown: the spark plug is composed of: porcelain part 1, center electrode 3, glass body 4, terminal 7, shell and side electrodes, porcelain part 1 is provided with a stepped shaft hole 2; center electrode 3 is opened from the end of the shaft hole 2 Insert and expose from the other end of the shaft hole 2; then fill the shaft hole 2 with glass powder from the end of the shaft hole 2 with a large opening; On the powder; the glass powder is melted at high temperature and then solidified to form a glass body, and the shaft hole 2 is blocked to achieve sealing. Since the press-fit part 6 is directly pressed on the glass powder, the glass body 4 formed after the glass powder melts and solidifies will stick to the press-fit part 9, making it difficult for the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com