Lateral lift pipe quick cyclone separation design method and reactor

A technology of rapid separation and design method of swirl flow, which is applied in the fields of petrochemical industry and fluidization, and can solve the problems of shortening oil and gas residence time, coking and coking in settlers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

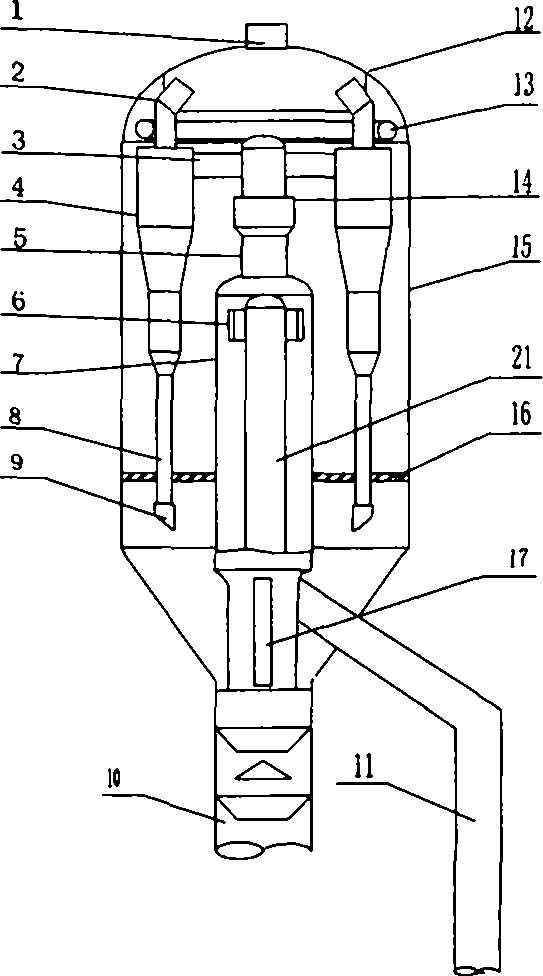

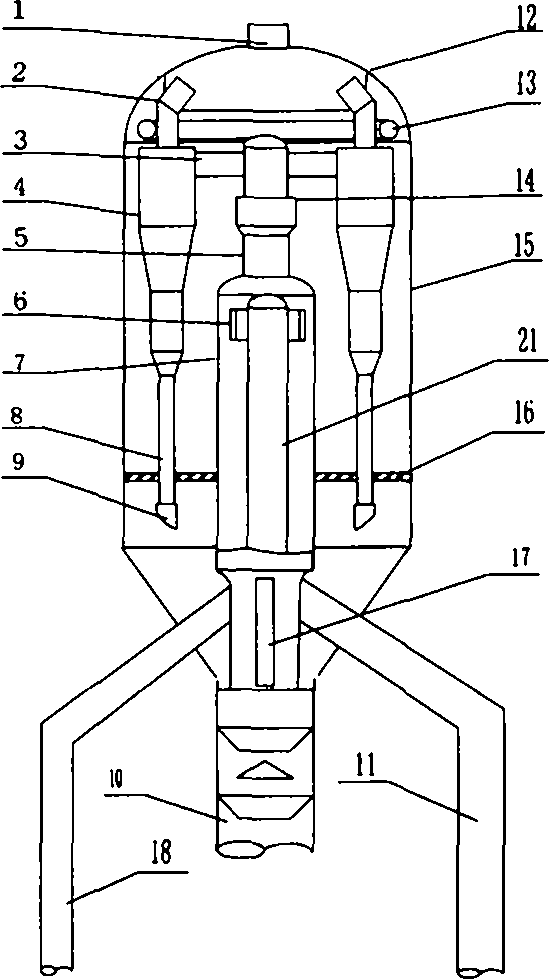

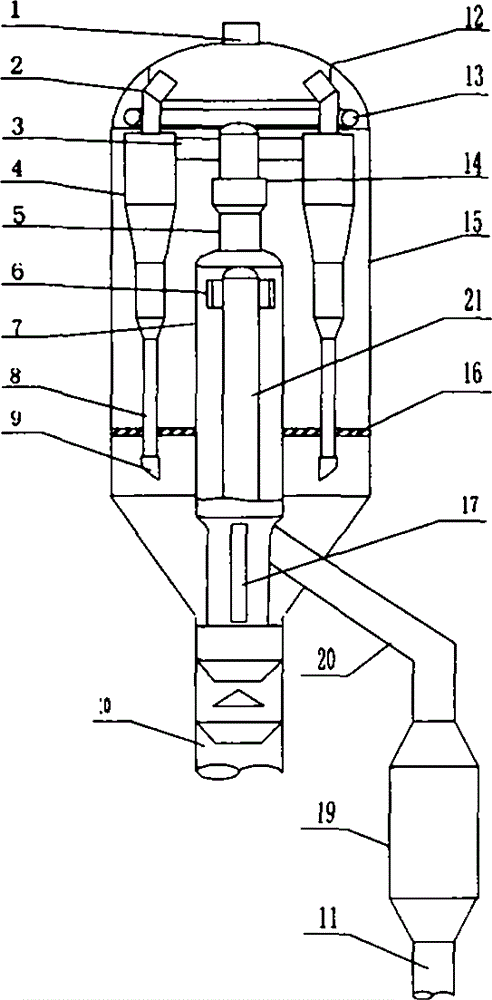

[0021] See Figure 1 ~ Figure 3 , figure 1 It is a single-side riser cyclone fast separation reactor, figure 2 It is a double-sided riser cyclone fast separation reactor, image 3 It is a side riser cyclone fast separation reactor with a fast bed reactor. The upper part of the settler 15 has an oil and gas outlet 1, a gas collection chamber 12 and an anti-coking steam ring pipe 13. The upper end of the central feeding pipe 21 extends into the inside of the sealing cover 7 and is connected with the cyclone 6 . The sealing cover 7 is a cylindrical structure, and the bottom is provided with some air windows 17, and the upper end is connected with the top rotation 4 through the sealing cover exhaust pipe 5 (compensator 14 is provided), the top rotation inlet pipe 3. The upper end of the top rotation 4 is connected to the gas collection chamber 12 through the top rotation exhaust pipe 2, and the lower end is connected to the dip leg 8 and the wing valve 9. An isolation plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com