Clamping jaw with pre-positioning function

A pre-positioning and gripper technology, which is applied in the field of automation equipment, can solve problems such as positioning deviation, affecting workpiece installation, and workpiece damage, and achieves the effect of guaranteeing the level, positioning accuracy, and preventing the workpiece from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

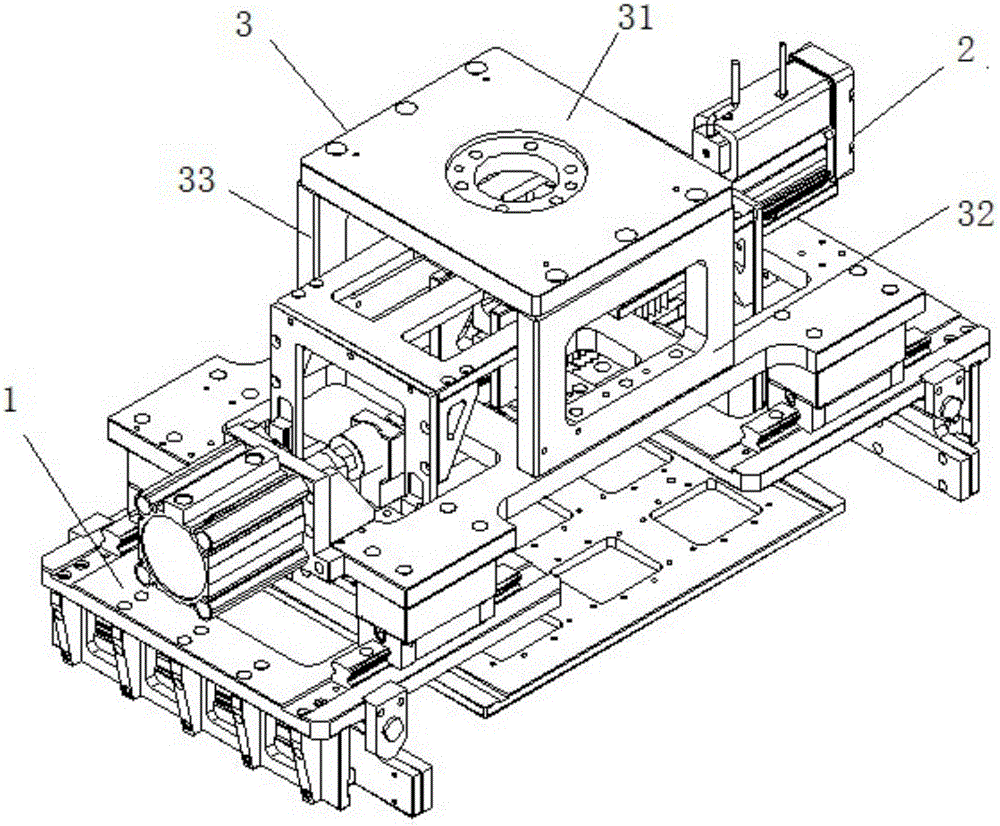

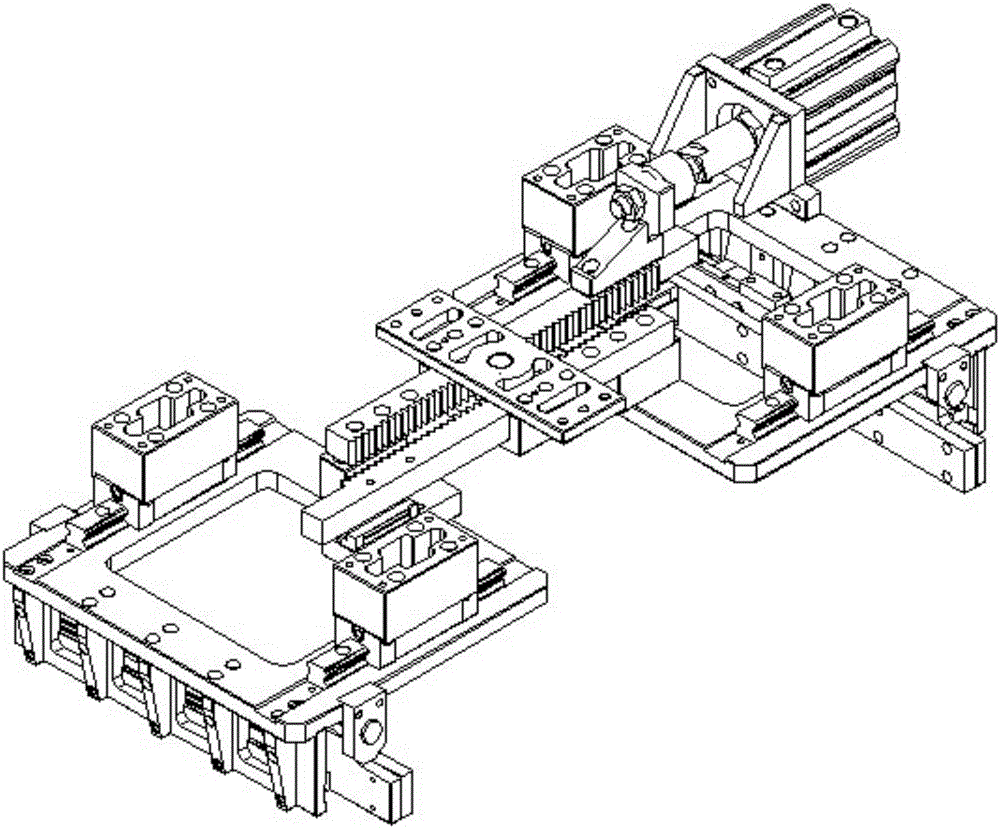

[0025] see Figure 1 to Figure 9 , a gripper with a pre-positioning function, including a gripper mechanism 1 and a pre-positioning mechanism 2 connected with the gripper mechanism 1, a connection mechanism 3 is provided on the pre-positioning mechanism 2, and the workpiece is pre-determined through the pre-positioning mechanism 2 position, and then the workpiece is clamped by the jaw mechanism 1.

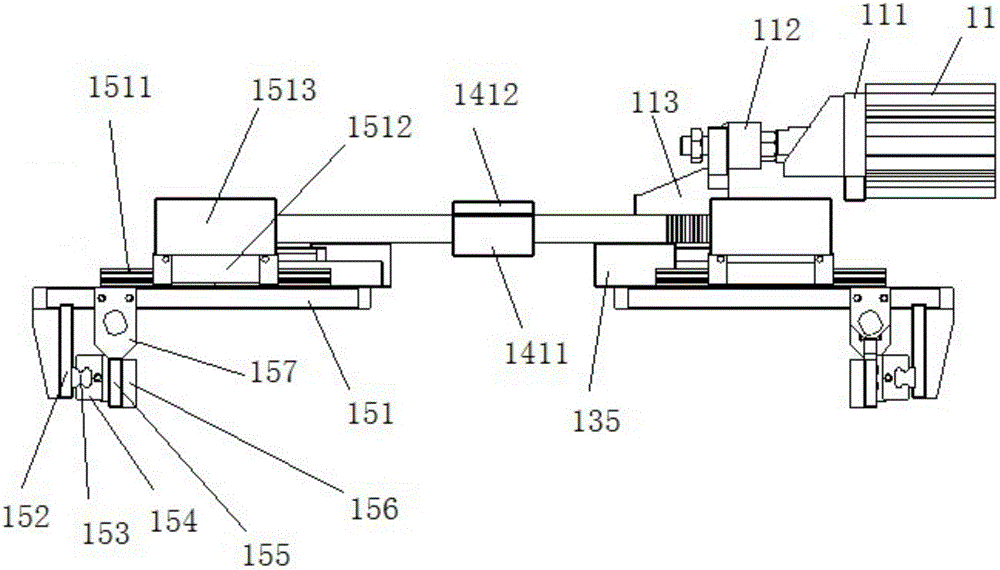

[0026] The jaw mechanism 1 includes two first jaw assemblies 15 and second jaw assemblies 16 that are symmetrically arranged and have the same structure, and a drive assembly for driving the first jaw assembly 15 and the second jaw assembly 16 to move synchronously, The drive assembly includes a cylinder 11, a cylinder connector 112 connected to the cylinder 11, a cylinder connection block 113 connected to the cylinder connector 112, a first rack assembly 12 connected to the cylinder connection block 113, and the cylinder 11 is connected to the cylinder through the cylinder fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com