Full-automatic pressing plate type coating and slicing machine

A slicing machine, fully automatic technology, applied in the field of machinery, can solve the problems of large product weight deviation, poor slicing accuracy, uneven gluing, etc., to achieve the effects of high precision, convenient operation and fast slicing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

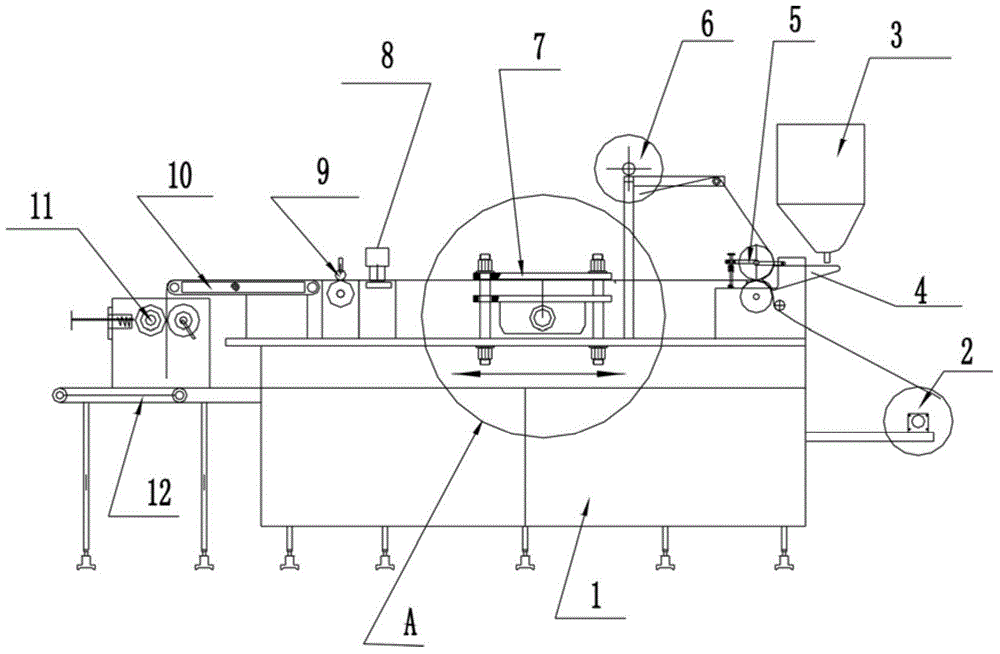

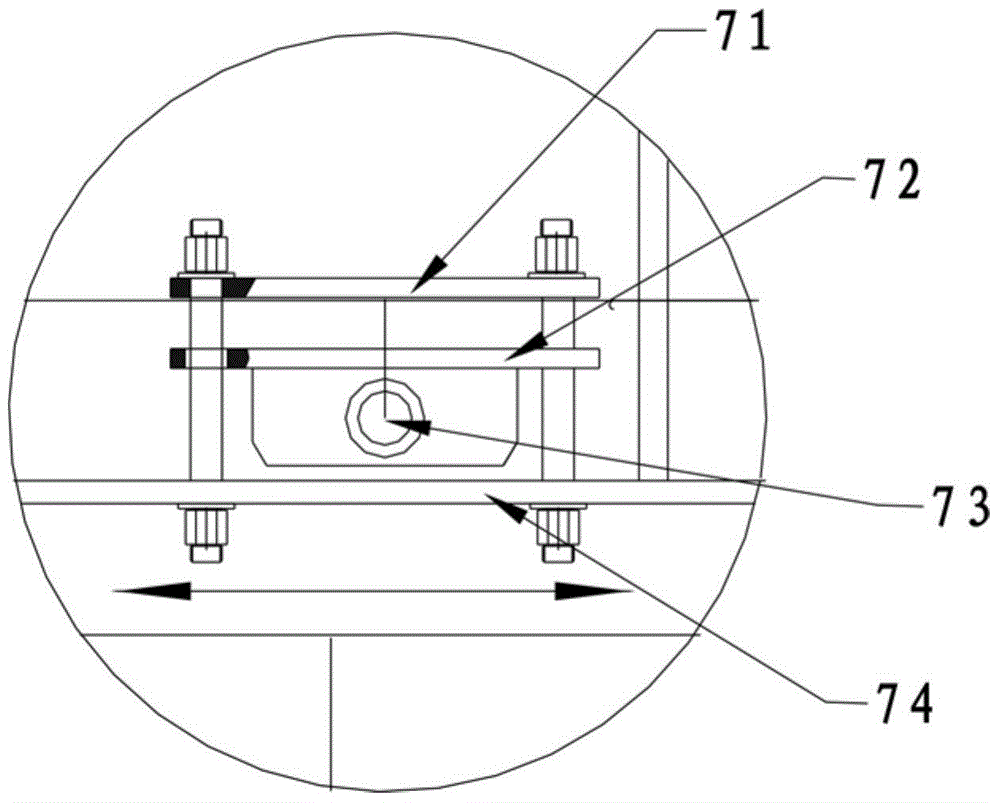

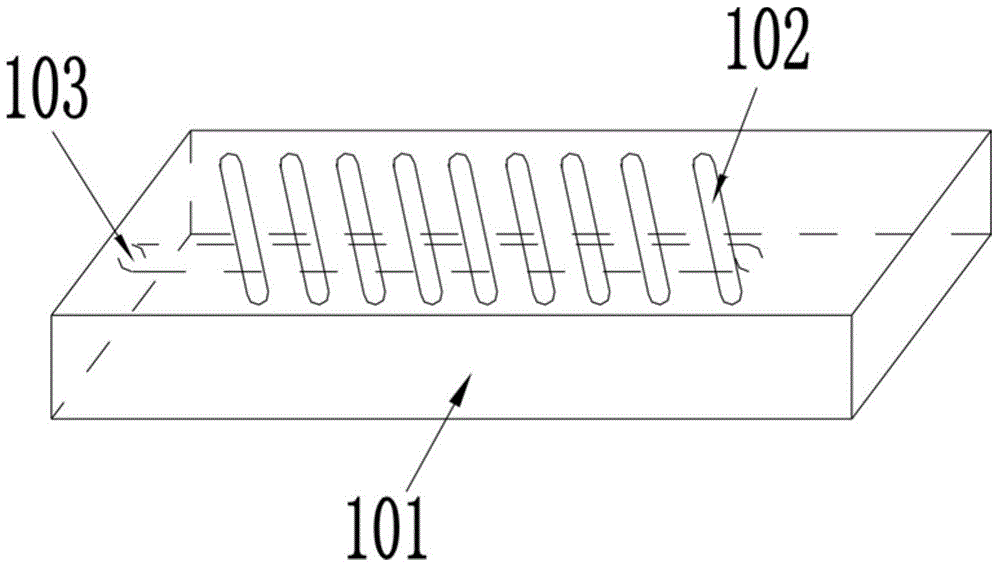

[0033] figure 1 It is a structural schematic diagram of a fully automatic platen coating slicer in an embodiment of the present invention, as figure 1 As shown, the fully automatic platen coating and slicing machine of this embodiment includes: a frame 1 and a unit arranged on the frame 1 .

[0034] Wherein the frame 1 is arranged on the ground, and plays a supporting role to the whole coating slicer.

[0035] The gel agent in the present invention is generally used for medical purposes, so the entire table top of the frame 1 is made of stainless steel or electroplated parts to improve hygiene requirements and produce products with higher quality.

[0036] The frame 1 is provided with a non-woven fabric reel 2, a gel bucket 3 and an embossed film reel 5 in sequence. The non-woven reel 2 provides a support carrier for the gel, and the gel bucket 4 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com