Landing leg locking device and engineering machinery with same

A technology of locking outriggers and locking plates, which is applied in transportation and packaging, vehicle maintenance, lifting vehicle accessories, etc., and can solve problems such as cumbersome operation and poor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

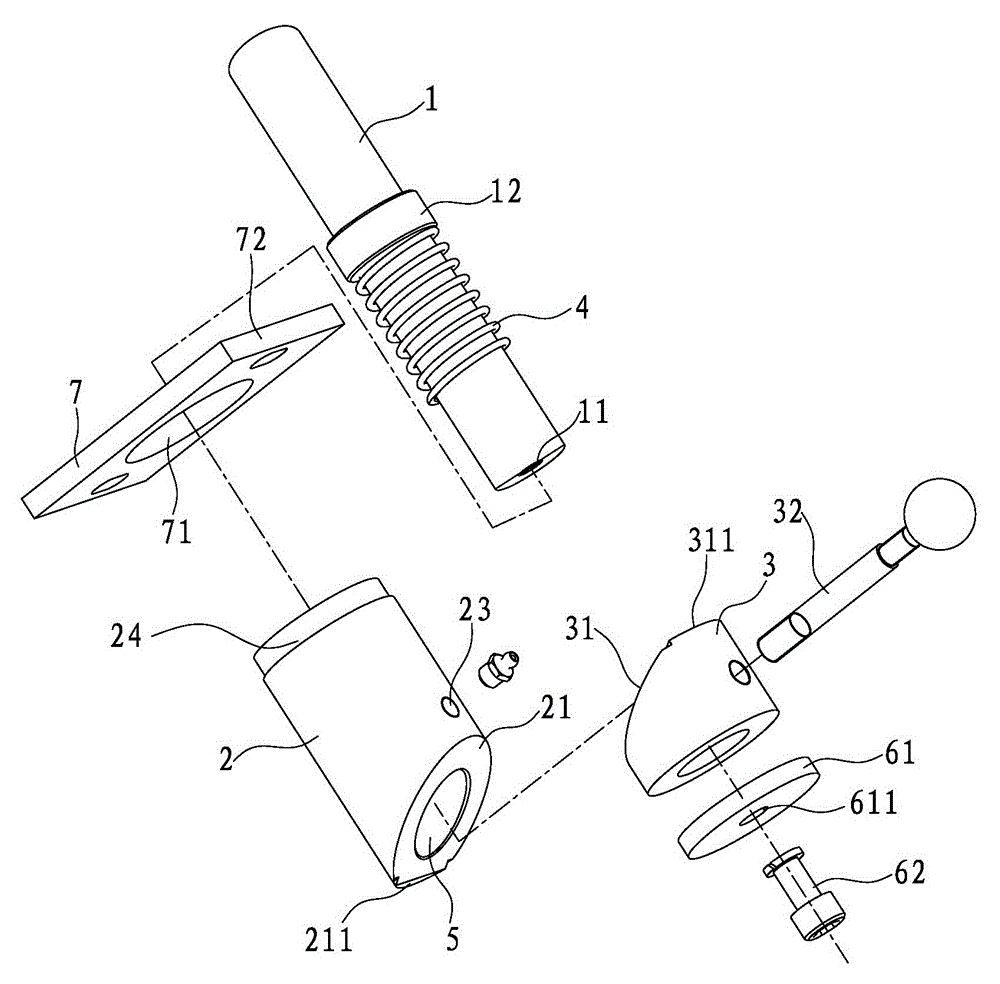

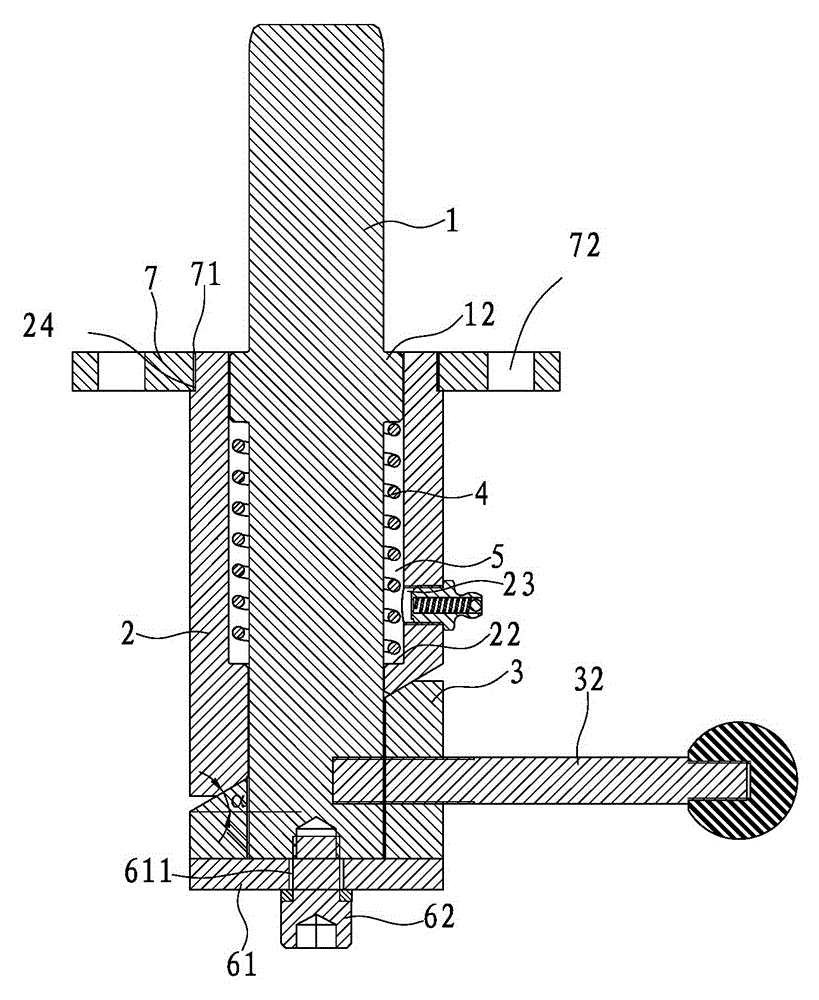

[0031] like figure 1 , figure 2 As shown, a locking device for outriggers includes a limit shaft 1, an upper round tube 2, a lower round tube 3 and a spring 4, and the upper round tube 2 and the lower round tube 3 respectively have oblique Cutting surfaces 21, 31, the angle α between the oblique cutting surface and the horizontal plane is 30°-60°, the oblique cutting surface of the upper round pipe and the oblique cutting surface of the lower round pipe are respectively provided with positioning surfaces 211, 311, the above two There is an included angle between the positioning surfaces in the initial state, that is, when the oblique cutting surfaces 21, 31 of the upper round tube 2 and the lower round tube 3 need to be rotated by a certain angle to match the respective positioning surfaces 211, 311 with each other, the range of the included angle can be Adjust according to actual needs, the included angle between the two positioning surfaces in this embodiment is 90°, and a...

Embodiment 2

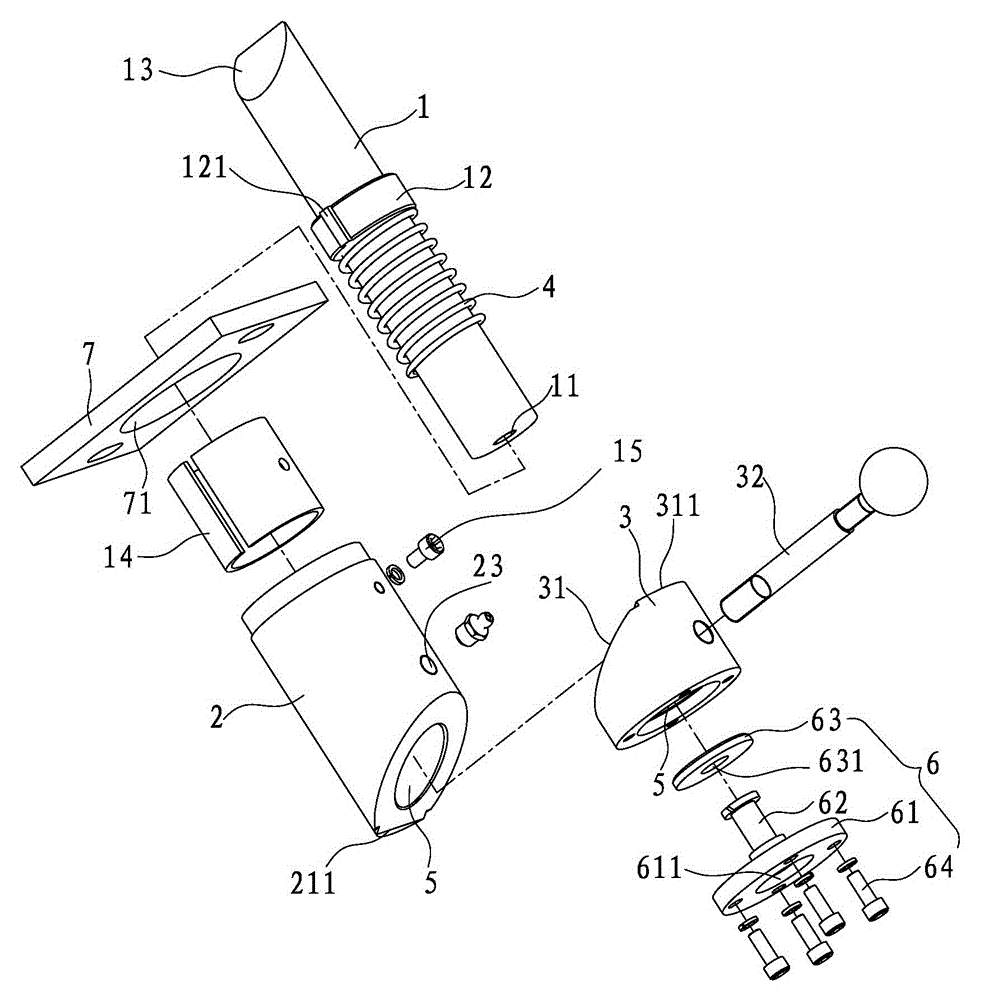

[0036] like image 3 , Figure 4As shown, the present invention also provides a more optimized outrigger locking device, the structure of which is basically the same as that of Embodiment 1, but the structure at the top of the limiting shaft, the matching structure between the positioning block and the upper round tube, and the limiting There is a difference in the positioning assembly between the bottom of the shaft and the lower round pipe, specifically: a bevel 13 is provided on the top of the limit shaft 1, and the bevel 13 is aligned with the bevel of the stop block 8 installed on the swing leg of the pump truck. The slope of the mouth is consistent to ensure that the two can cooperate with each other when they are in contact with each other; a longitudinal flange 121 is provided on the positioning block 12 of the limit shaft 1, and a chute is provided on the inner wall of the upper circular tube 2 (Fig. not shown) or by fixing a directional tube 14 with a chute by bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com