Pressing sliding door

A sliding door and threshold technology, applied in the field of doors and windows, can solve the problems of difficult to change watertight performance and airtight performance, watertight performance, poor airtight performance, shortened service life of sliding doors, etc. The effect of watertightness and airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

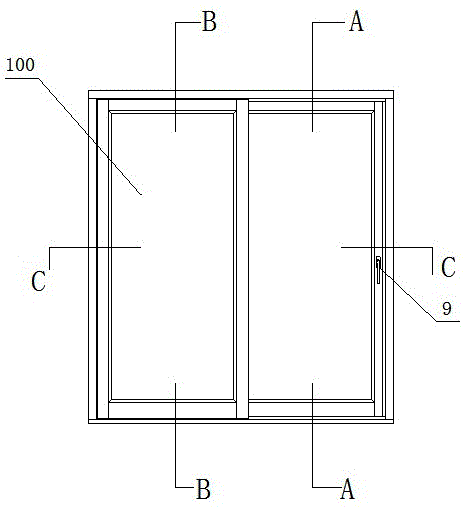

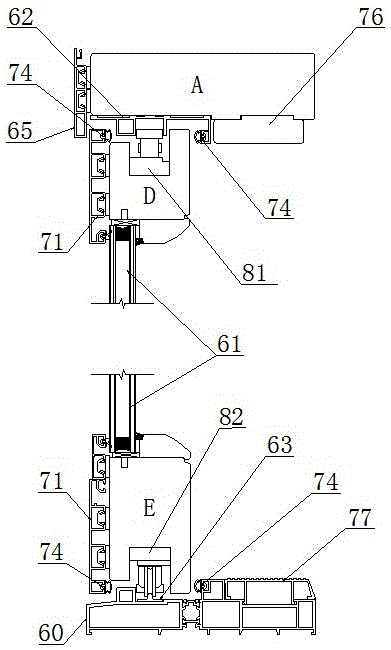

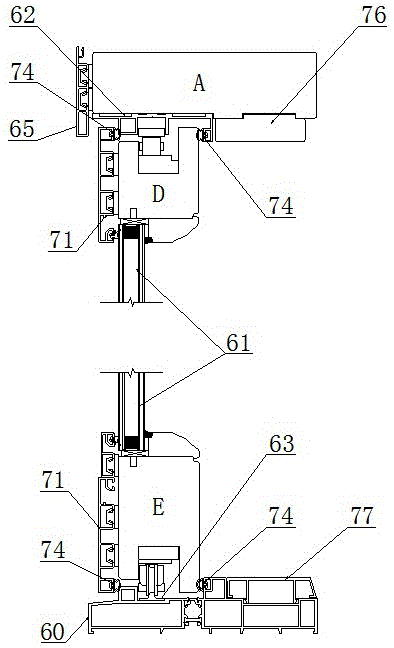

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 with Figure 23 As shown, the present embodiment is an aluminum-clad wood press-fit sliding door, the fixed fan 100 is inside the left end room, and the push-pull fan 200 is outside the right end room. This embodiment includes a door frame consisting of an upper frame A, a threshold 60, a left frame B and a right frame C, an upper fixed sash frame F, a lower fixed sash frame G, a left fixed sash frame J, a right fixed sash frame K and glass 61 The fixed fan 100 that forms is made up of the push-pull fan 200 and the hardware system made up of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com