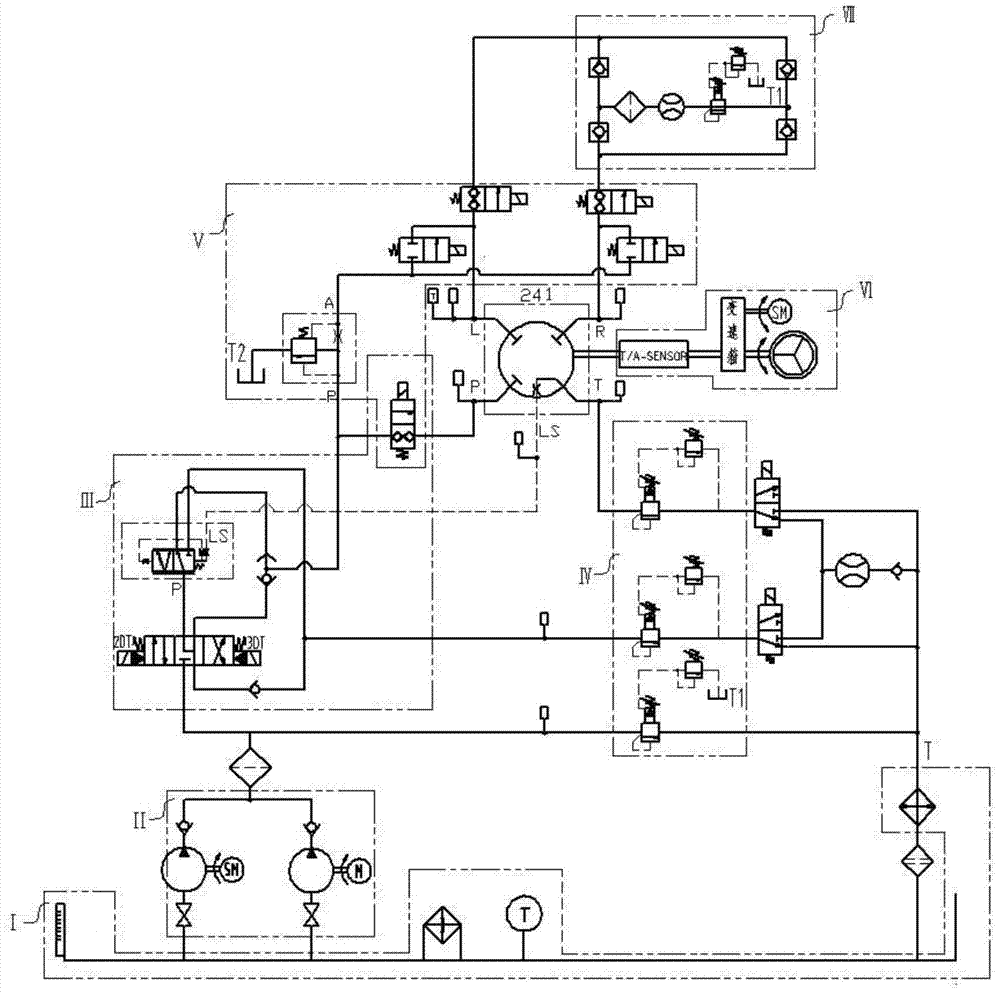

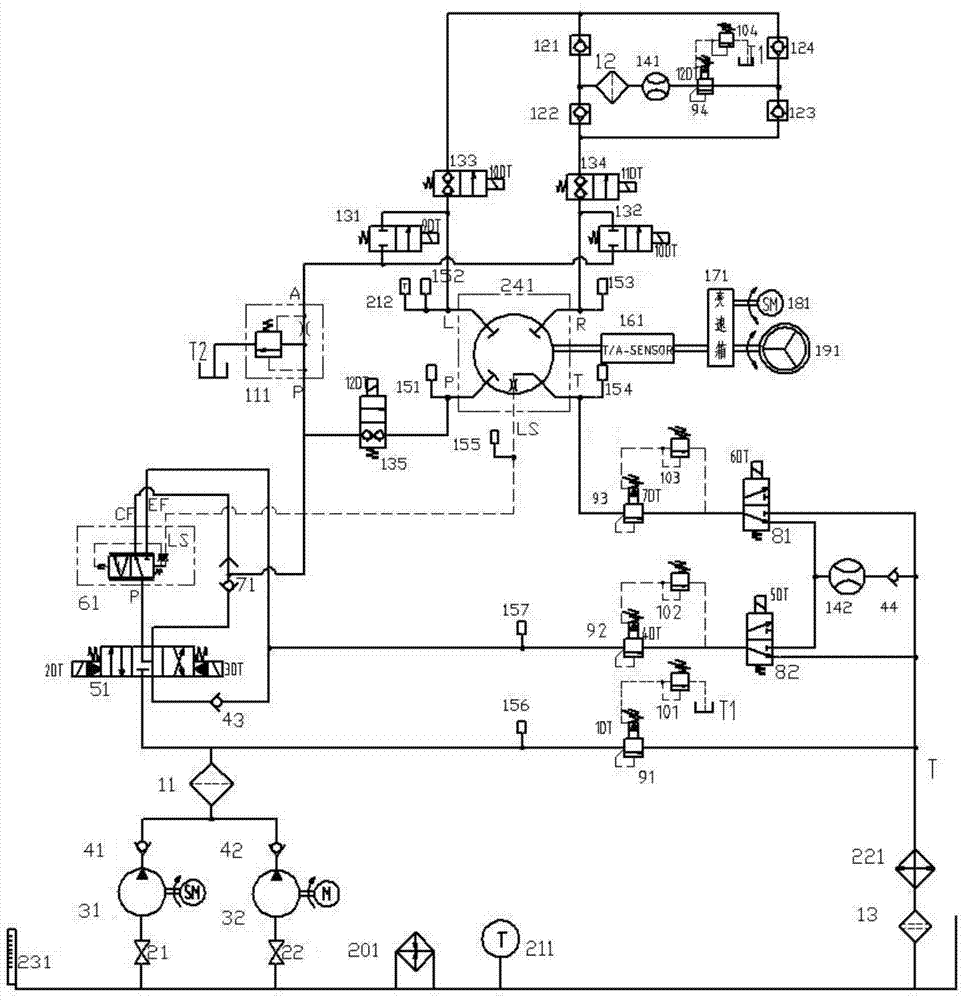

Multifunctional test system for full hydraulic steering gear

A multifunctional test and steering gear technology, applied in the field of hydraulic systems, can solve the problems of different performance requirements of test items, high system pressure loss, cumbersome operation, etc., achieve accurate and intuitive test results, small system pressure loss, and fast operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0058] A. Steering wheel rotation speed adjustment: start the servo motor 181, and adjust the control knob to the left (or right) to obtain the desired steering wheel rotation speed.

[0059] B. System pressure regulation: energize the electromagnet 6DT, start the variable frequency motor pump group 31 and the ordinary motor pump group 32 (the frequency conversion motor pump group 31 will not be started when the test flow rate of the steering gear 241 is less than 80L / min), and adjust the frequency conversion of the variable frequency motor pump group 31 The adjusting knob of the motor sets the test flow rate of the steering gear 241 under test; the three-positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com