Automatic detection device for dust baffle production and working method

A technology for automatic detection and dust baffles, applied in measuring devices, mechanical devices, mechanical measuring devices, etc., can solve problems such as low efficiency, reduced product qualification rate, low measurement efficiency, etc., to achieve simple operation and measurement, and improved measurement efficiency. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

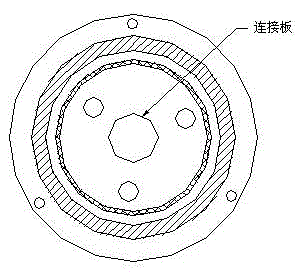

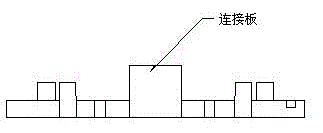

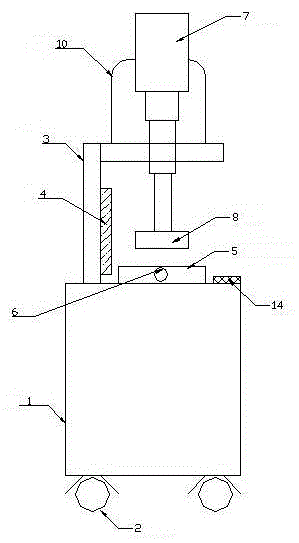

[0025] further as image 3 , Figure 4 and Figure 5 As shown, another aspect of the present invention provides a working method of an automatic detection device for dust shield production. During detection, firstly, the dust shield to be measured is inserted into the limit post 11 arranged on the dust shield fixing seat 5 Inside, the dust shield to be measured is fixed by the silk-type adjusting bolt 6 provided on the dust shield fixing seat 5, and then the control unit 14 is used to control the cylinder 7 to drive the mold base 8 with the same structure as the dust shield to be measured. Press, finally observe the scale scale 9 on the connecting part of the linkage rod 7 and the mold base 8, whether the error is within the allowable range, if so continue to the next process, if not, just select it; the control assembly 14 in this structure receives the sensor in real time The pressure information fed back by 13 controls the stroke of the cylinder 7 to prevent damage to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com