Safety tentacle

A technology of safety tentacles and tentacles, applied in the direction of measuring devices, instruments, etc., can solve problems such as complex structures, personal casualties, steel coils or equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

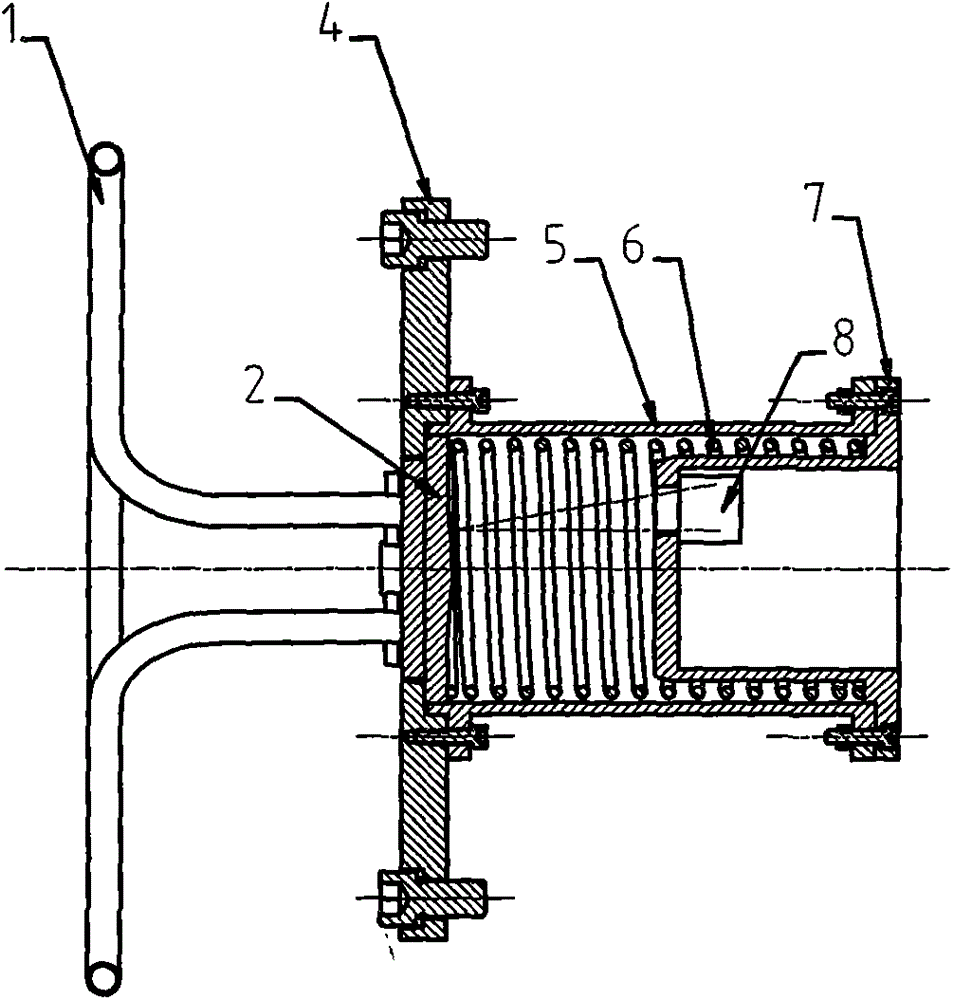

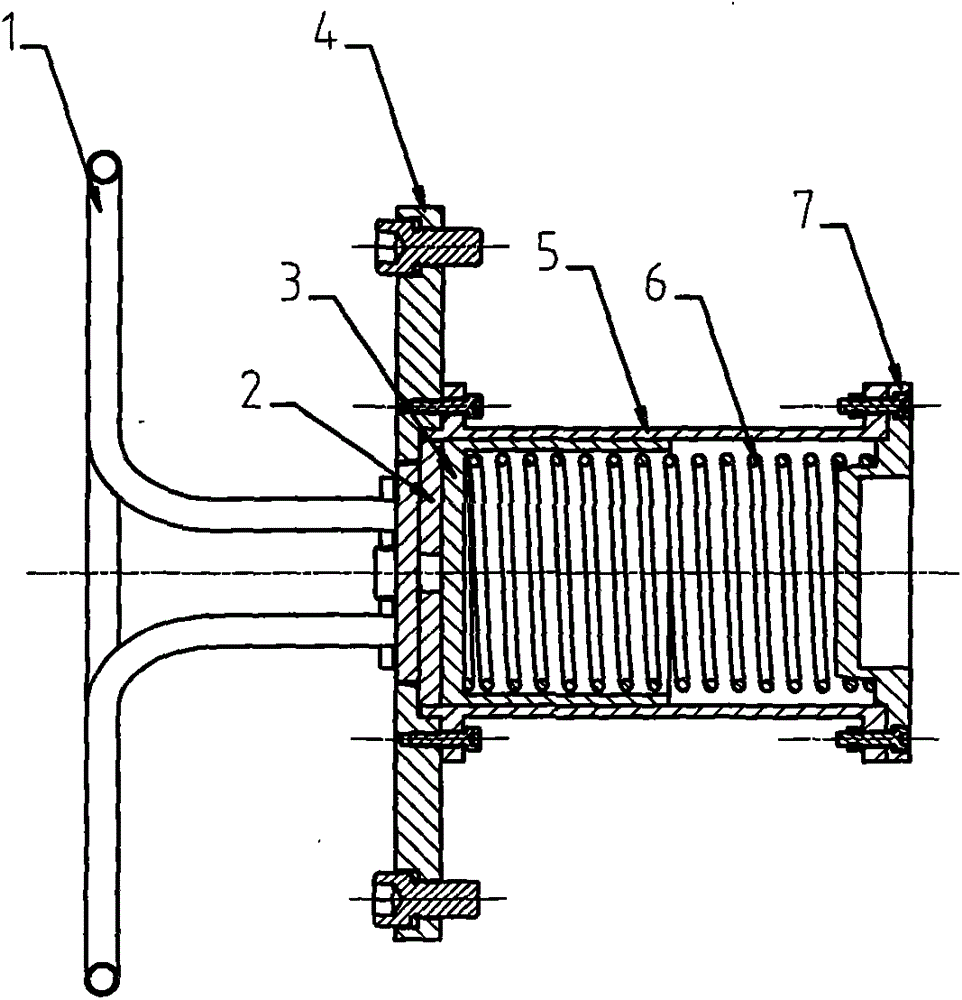

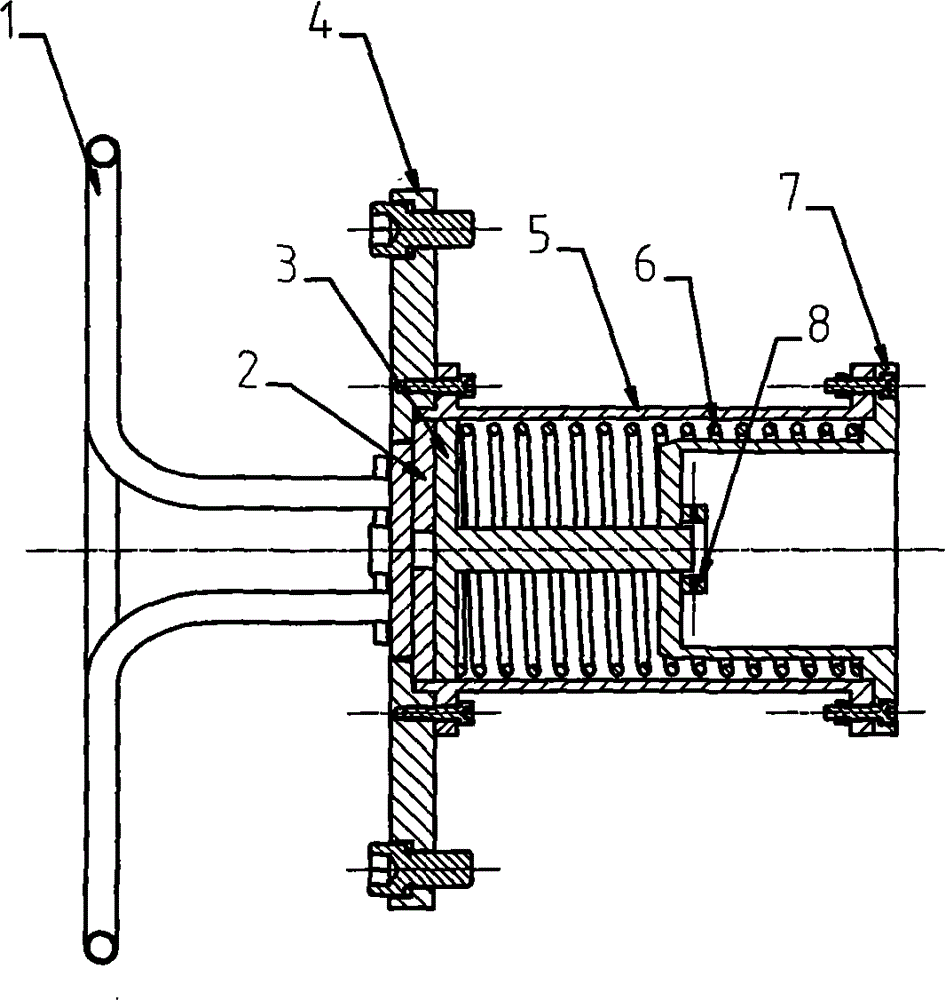

[0012] The shape of the disc-shaped part used as the tentacles must be smaller than the shape of the corresponding position of the inserted object, and at the same time need to be larger than the shape of the object inserted later. The shape of the adjustment bar is the shape of the aforementioned equipment used in the production of steel coils, and it can also be applied to The end of the coiling shaft of the uncoiler, taking the above-mentioned adjusting rod as an example, the steel coil has a circular eye, so it is easiest to make the tentacles into a ring. In order to connect the tentacles (1) and the swing plate (2) together , the tentacles (1) also need to contain the parts required for the connection, figure 1 The tentacles (1) of the shown embodiment are like a steering wheel, and it includes a circular ring (hereinafter referred to as the tentacles ring), the spokes supporting the tentacles ring and a link, and the spokes are used to support the tentacles ring, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com