Half box sliding push drive fixture

A technology of driving jig and half-box sliding push, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of few driving jigs, etc., and achieves low manufacturing cost, reasonable component configuration and compact structure. concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

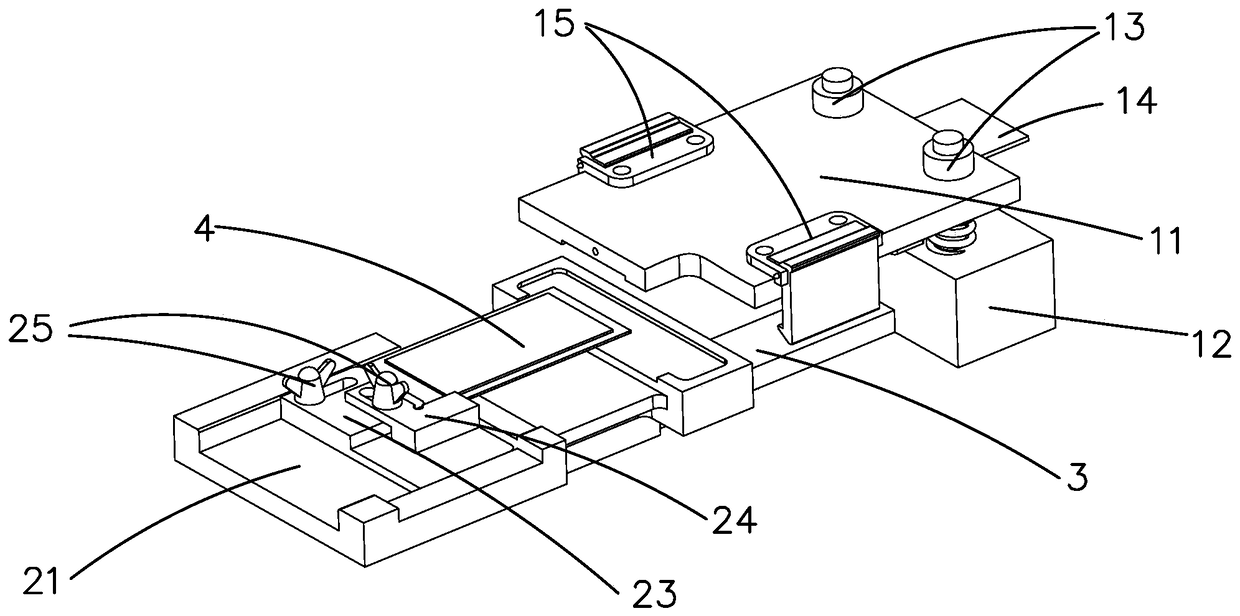

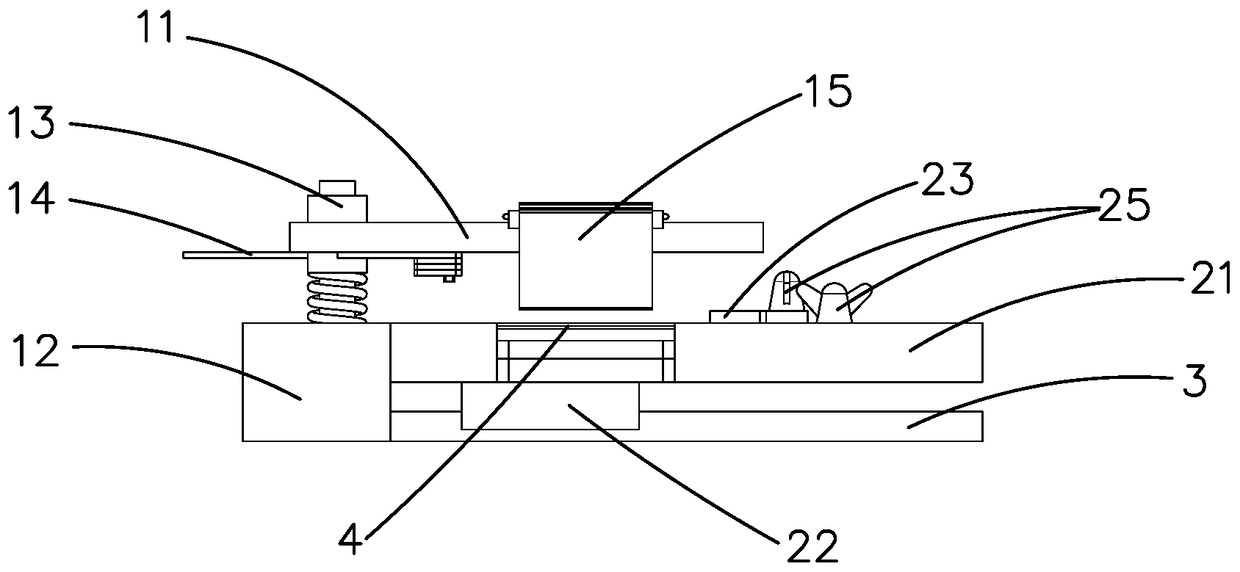

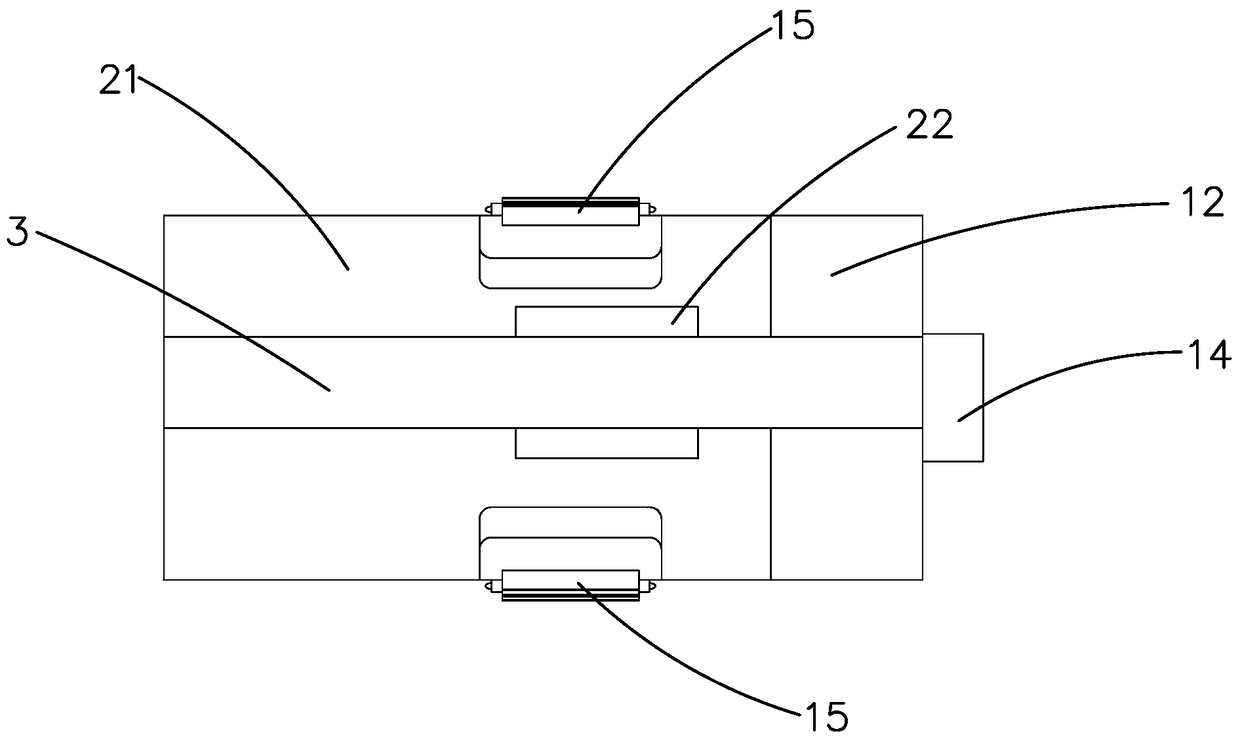

[0018] Such as Figure 1-3 As shown, the structure diagram of the semi-box slide-push driving jig provided by the present invention includes a first base plate, a second base plate and a slide rail 3 . Wherein, the first substrate includes a platform one 11, a base 12 and an adjustment mechanism 13, the adjustment mechanism 13 is arranged between the platform one 11 and the base 12, so that the platform one 11 can move vertically relative to the second substrate, and the base 12 is fixedly arranged on a slide on track 3. The second substrate includes a platform two 21 and a clip 22, the clip 22 is slidably connected to the slide rail 3, so that the second substrate can slide along the slide rail 3 to the bottom of the platform one 11, and the platform two 21 is used to place the OLED4. A positioning mechanism is arranged on it, and the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com