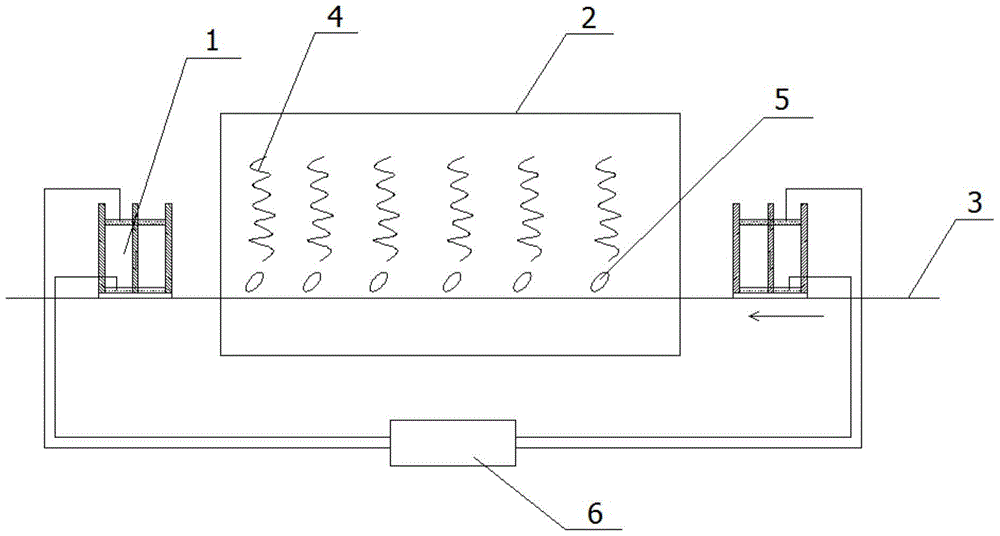

Mass production device and method for rapidly improving light-induced attenuation of p-type crystalline silicon cells

A crystalline silicon cell, light-induced attenuation technology, applied in the field of solar cells, can solve problems such as difficulty in mass production, decreased cell and module efficiency, and increased production costs, to improve processing efficiency and product quality, shorten processing time, The effect of uniform air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

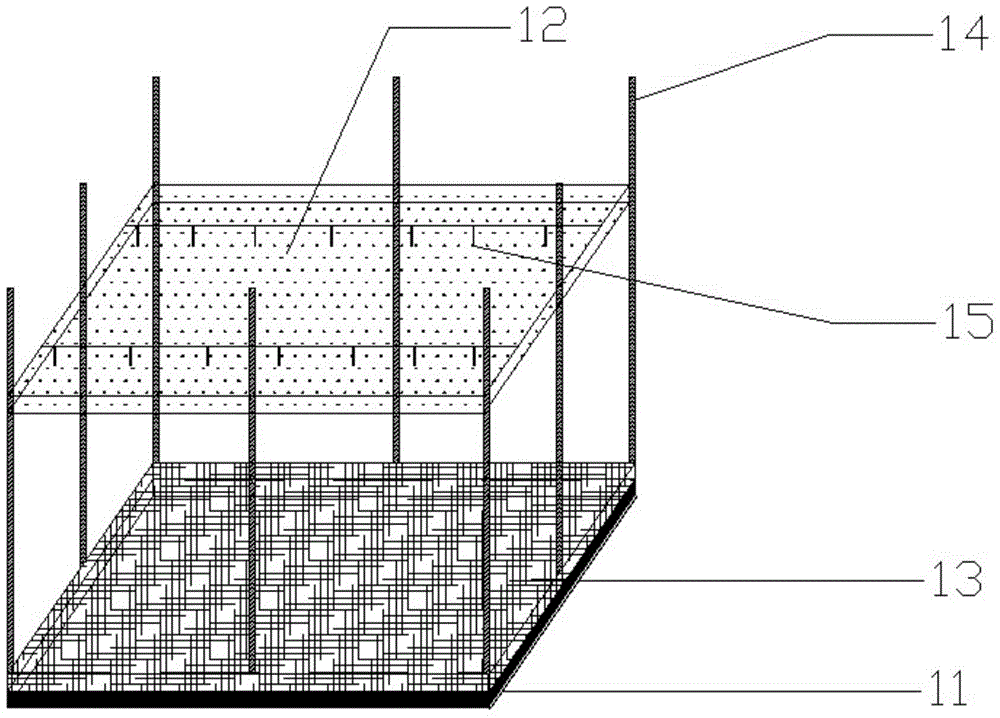

Embodiment 1

[0036] Stack 100 p-type monocrystalline silicon solar cells in the order of all fronts and put them into the silicon wafer carrier box, and use DC power supply to energize, and the current density is set to 1000mA / cm 2 , Keep the temperature of the incubator at 250℃, set the conveyor speed to make the silicon wafer carrier box pass through the incubator for 15 minutes, and take out the battery after it cools naturally. Compare the processed cells with the unprocessed cells of the same batch, and the results are as follows:

[0037]

Embodiment 2

[0039] Stack 200 p-type polysilicon solar cells in the order of all fronts and put them into the silicon wafer carrier box, and use DC power supply to energize, and the current density is set to 3000mA / cm 2 , Keep the temperature of the incubator at 375°C, set the conveyor speed to make the silicon wafer carrier box pass through the incubator for 8 minutes, and take out the cell after it cools naturally. Compare the processed cells with the unprocessed cells of the same batch. The results are as follows:

[0040]

Embodiment 3

[0042] Stack 55 p-type monocrystalline silicon solar cells in the order of all fronts and put them into the silicon wafer carrier box, use pulsed power supply to energize, and set the current density to 501mA / cm 2 , Keep the temperature of the incubator at 230°C, set the conveyor speed to make the silicon wafer carrier box pass through the incubator for 20 minutes, and take out the cell after it cools naturally. Compare the processed cells with the unprocessed cells of the same batch. The results are as follows:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com