Position sensor

A sensor and part technology, applied in instruments, light guides, optics, etc., can solve the problem of inability to detect accurate pressing positions, and achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

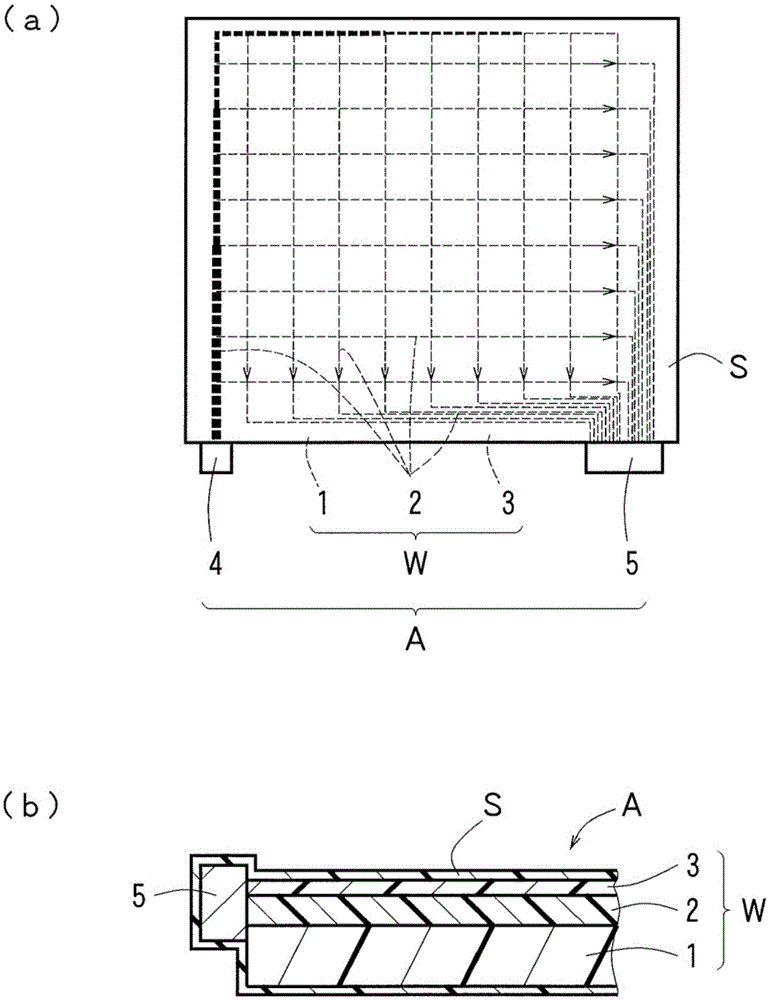

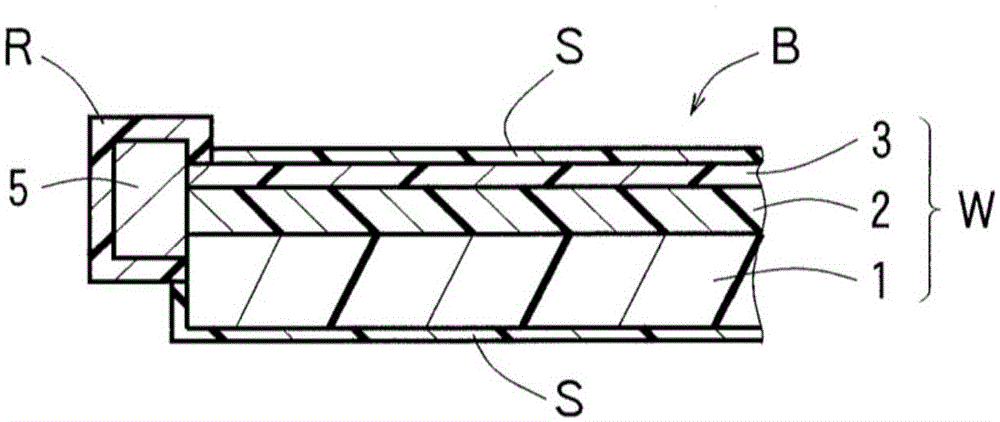

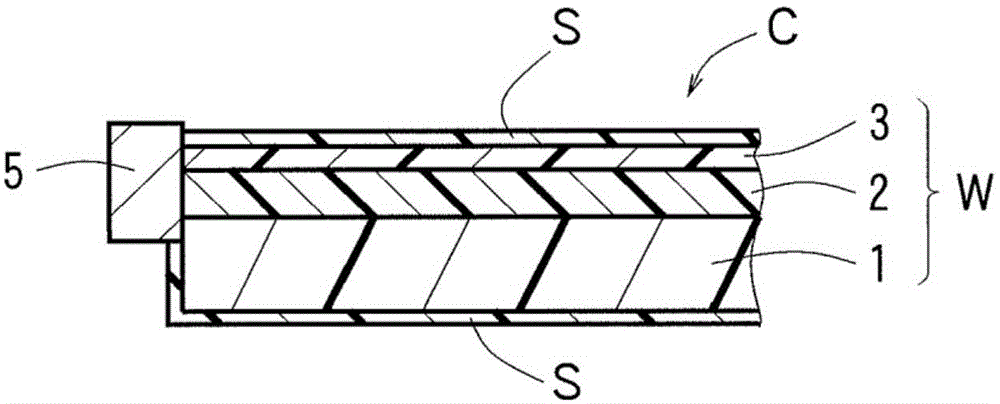

[0041] As a position sensor, a device whose entirety is covered with a light-shielding layer is prepared (refer to figure 1 (a), (b)). That is, the upper surface of the upper cladding layer of the position sensor is coated with a light-shielding sheet (75 μm in thickness) by means of a double-sided adhesive tape (25 μm in thickness), and the lower surface of the lower cladding layer is covered by a light-shielding sheet (75 μm in thickness) by means of a double-sided adhesive tape (50 μm in thickness). A light-shielding plate (thickness 1 mm) is covered, and the outer surface of the light-emitting element and the outer surface of the light-receiving element are covered by a light-absorbing resin layer. In addition, the end face of the core, the light-emitting element, and the light-receiving element are bonded using ultraviolet curable resin. The forming materials and the like of each structure are as follows.

[0042] (light shielding layer and double-sided tape)

[0043]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com