Multifunctional remote monitoring system for baking room

A remote monitoring and multi-functional technology, applied in the field of multi-functional remote monitoring systems for barns, can solve the problems of running around, increasing the workload of staff, reducing monitoring efficiency, etc., and achieving the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

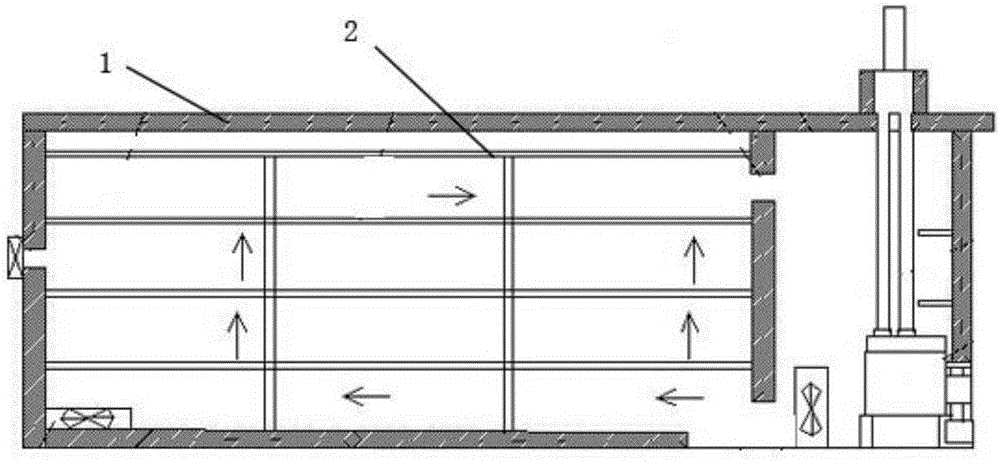

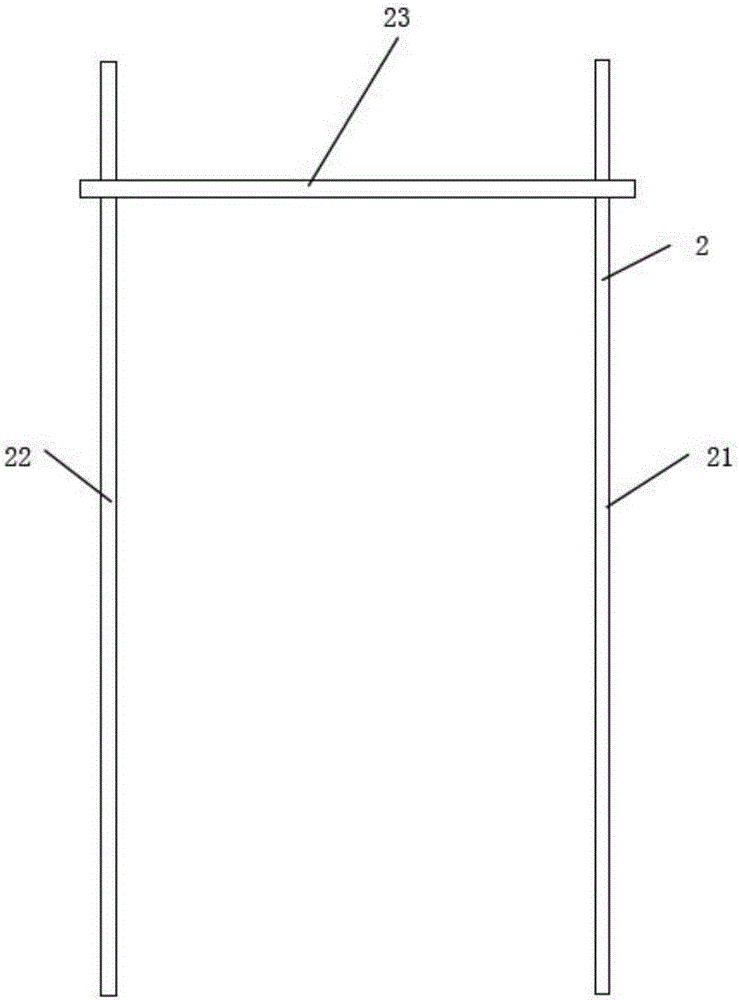

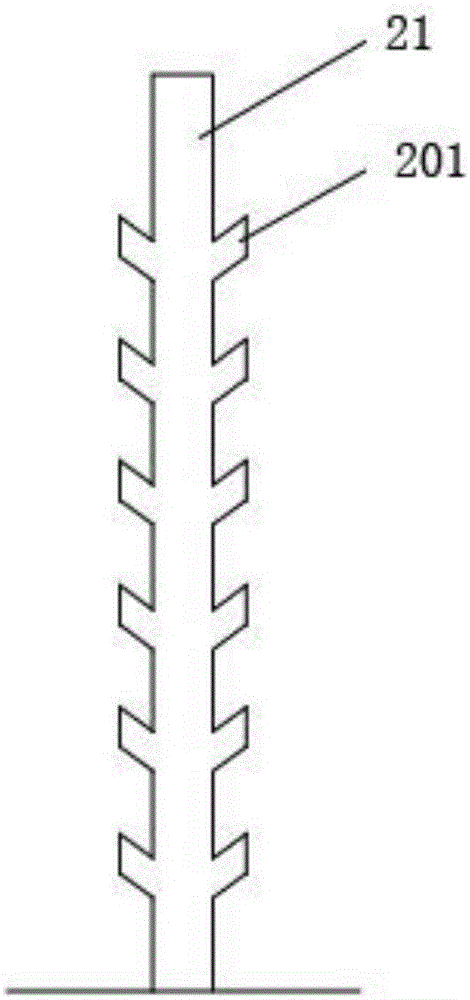

[0038] like Figure 1~4 As shown, the barn used by the monitoring system provided by the present invention includes a barn body 1 and several groups of tobacco hanging racks 2 installed in the barn body 1, and the tobacco hanging racks 2 include vertically arranged first vertical rods 21 , the second vertical bar 22 and the horizontal bar 23 arranged horizontally, the first vertical bar 21 and the second vertical bar 22 are provided with a plurality of clamping parts 201 for clamping the horizontal bar 23 .

[0039] like Figure 7 As shown, the weight monitoring system includes weight data acquisition components, temperature data acquisition components, humidity data acquisition components, image data acquisition components, data transmission components, control components and terminals installed in the barn;

[0040]Described weight data acquisition element comprises first weight data acquisition element 3, the second weight data acquisition element 4, as Figure 5 , 6 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com