A New Type of Automatic Dishwasher

An automatic dishwasher, a new type of technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, household cleaning devices, etc., can solve the problem of long cleaning time, inability to wash and use immediately, and consumption Water and energy consumption and other issues, to achieve the effect of convenient and fast use cost, dishwashing efficiency, ready to use, and high dishwashing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

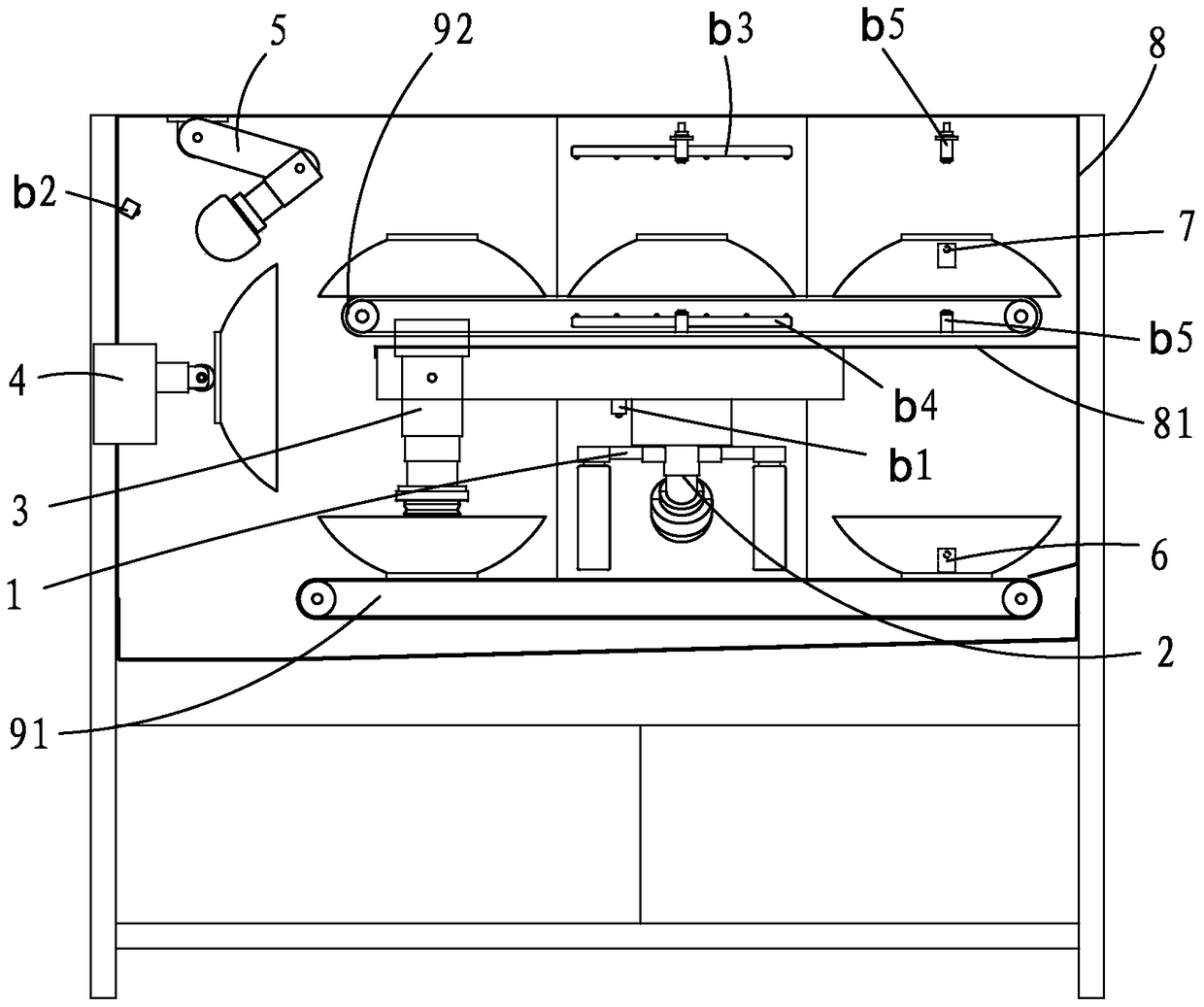

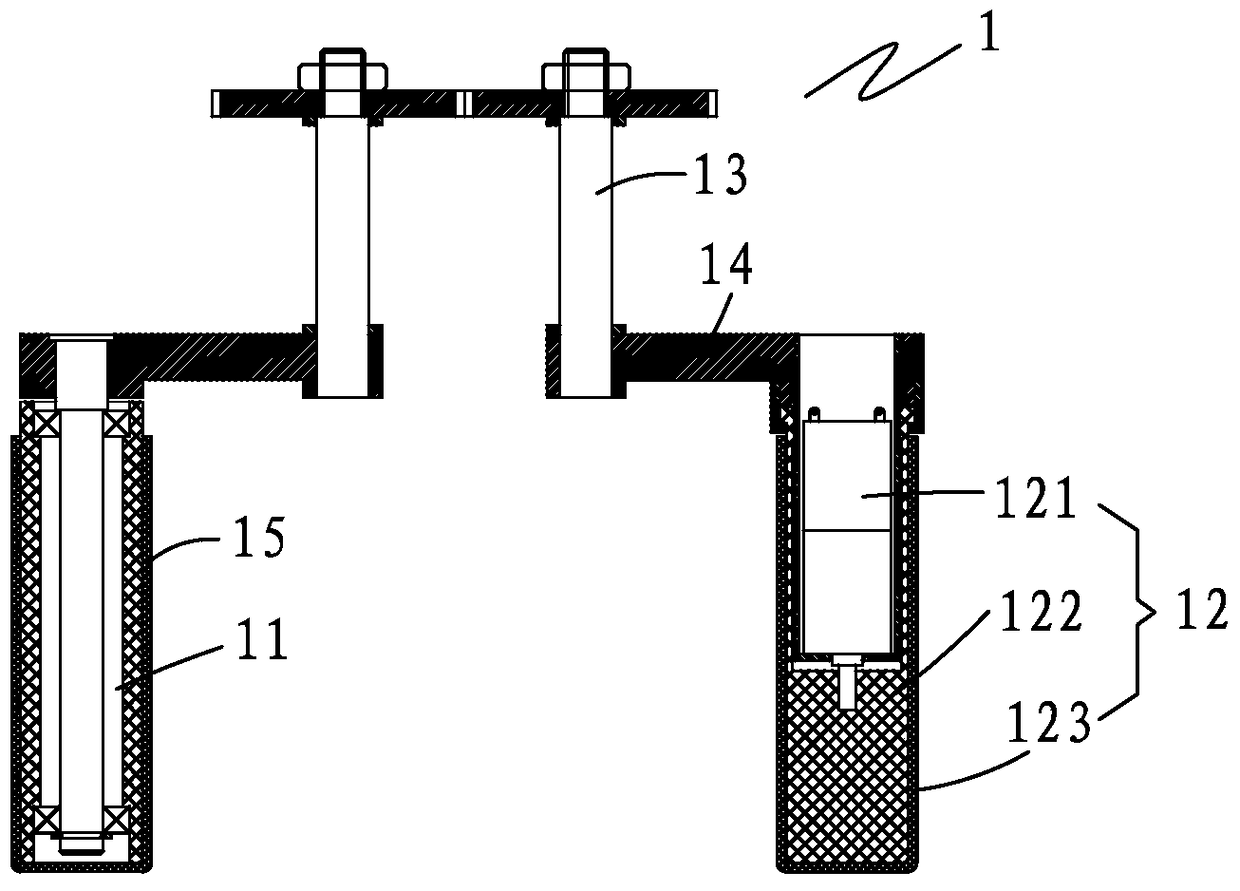

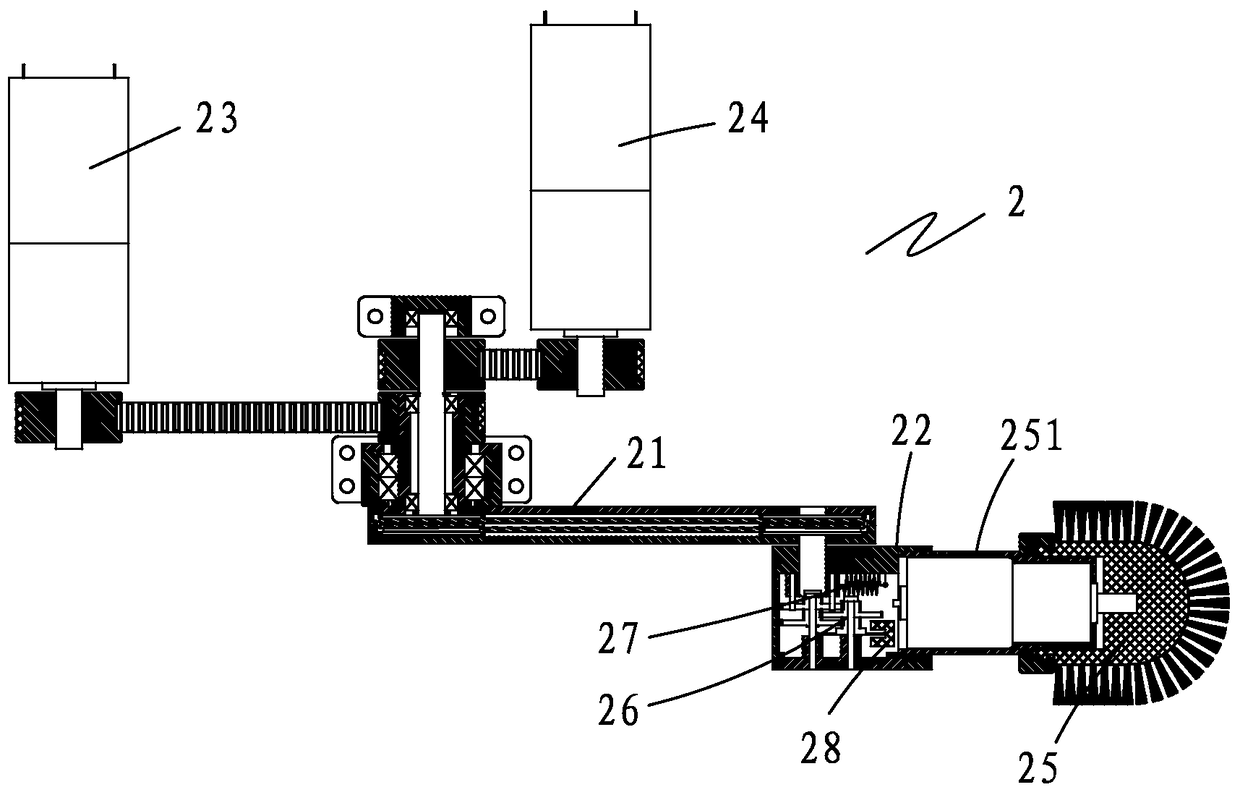

[0024] see Figure 1 to Figure 5 As shown, a new type of automatic dishwasher includes a clamping mechanism 1, a first scrubbing mechanism 2, a telescopic adsorption mechanism 3, a telescopic rotating mechanism 4, a controller (not shown in the figure), a second scrubbing mechanism 5, a first Infrared reflector 6, the second infrared reflector 7, fixed frame 8 and transmission mechanism 9, described transmission mechanism 9, clamping mechanism 1, first scrubbing mechanism 2, telescopic adsorption mechanism 3, telescopic rotation mechanism 4 and the second Two scrubbing mechanisms 5 are arranged in the fixed frame 8, and the first infrared injector 6, the clamping mechanism 1 and the retractable adsorption mechanism 3 are successively arranged on the conveying mechanism 9, and the first scrubbing mechanism 2 is arranged In the clamping mechanism 1, the telescopic rotation mechanism 4 is arranged on one side of the fixed frame 8, and is opposite to the telescopic adsorption mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com