A glue injection device

A glue injection device and glue injection technology, applied in the glue injection field, can solve the problems of glue drop, glue backflow, waste of resources, etc., and achieve the effects of easy disassembly, increased resistance, and simple coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Those skilled in the art will be more aware of the above and other objects, advantages and features of the present invention according to the following detailed description of specific embodiments of the present invention in conjunction with the accompanying drawings.

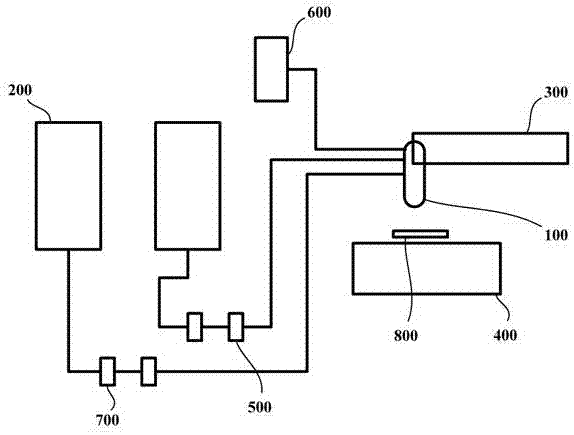

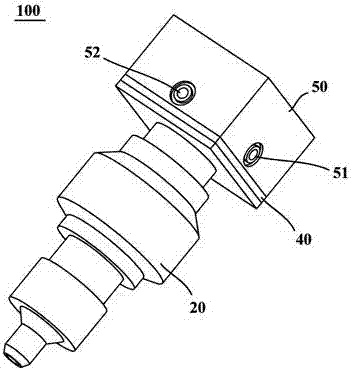

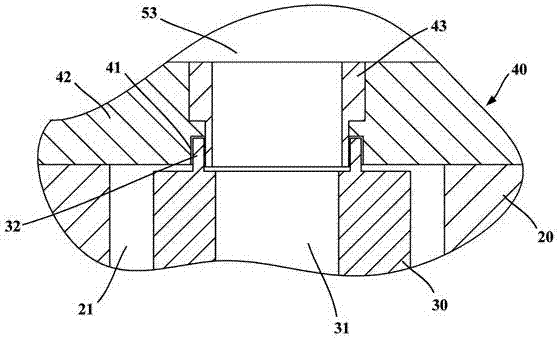

[0031] figure 1 is a schematic schematic diagram of a glue injection device according to an embodiment of the present invention. Such as figure 1 As shown, the glue injection device may include at least one glue tank 200, at least one pumping device 500, a glue injection head 100, a moving mechanism 300, a working platform 400 and a control device. Each glue tank 200 is used to hold glue liquid. The glue injection head 100 is installed on the moving mechanism 300 to move according to a preset track driven by the movement mechanism 300 . The glue injection head 100 is provided with at least one glue inlet hole 51 , and a glue injection channel is defined in the glue injection head 100 . Each pumping de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com