Gas meter magnetic steel set assembling mechanism

A technology for assembling mechanism and gas meter, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of labor, labor intensity of workers, and low operating efficiency of workers, and achieves convenient use, continuous assembly, and reduction of manpower. Costs and effects of managing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

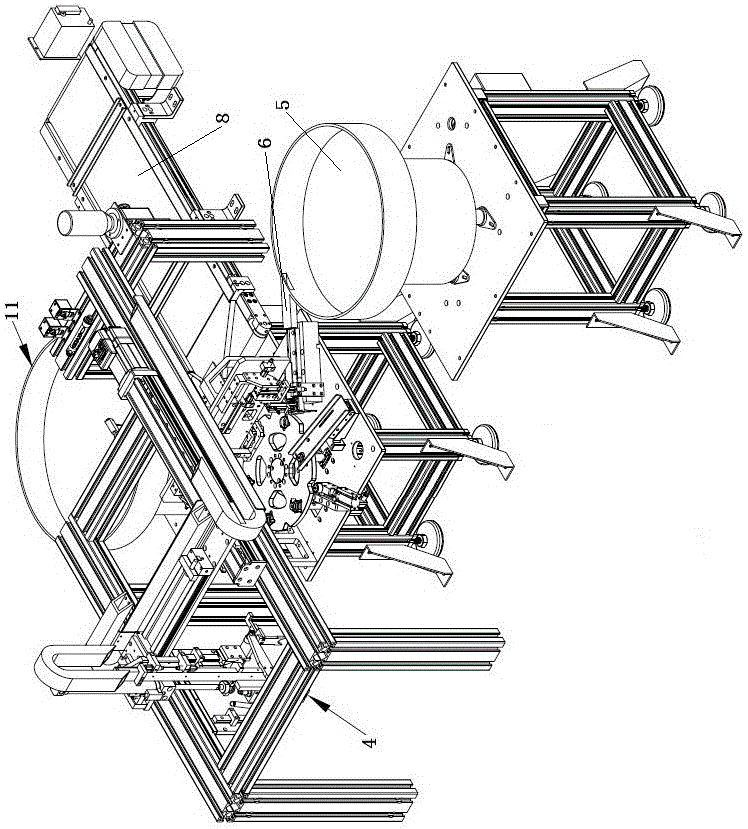

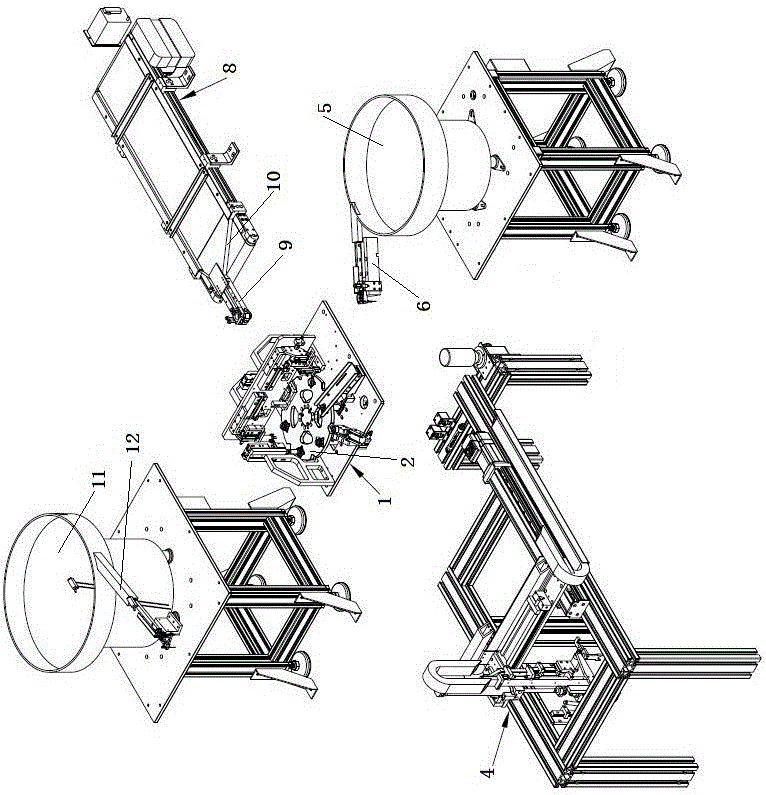

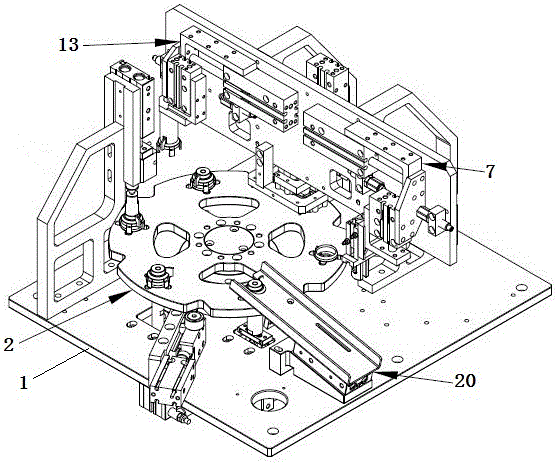

[0040] As shown in the figure, the gas meter magnetic steel group assembly mechanism of the present invention includes a base 1, a rotating disk 2 located above the base 1, a rotating device that can drive the rotating disk 2 to rotate around its center, and is arranged on the rotating disk 2. The workpiece tank 3, the outer jacket conveying device, the magnetic steel conveying device, the inner sleeve conveying device, the finished product grasping device 4 capable of taking out the prepared magnetic steel group from the workpiece groove 3, the locking device, and the locking device arranged on the base 1 Detection device, waste rejection device. In this embodiment, six workpiece grooves 3 are evenly distributed on the rotating disk 2, and the workpiece grooves 3 are located on the same circle as the center of the rotating disk 2, and the angle between two adjacent workpiece grooves 3 and the center of the rotating disk 2 is 6°. °.

[0041] Wherein, the locking device includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com