A pressing plate suitable for pre-pressing feeder

A technology of a feeder and a pressing plate, applied in the field of wood product manufacturing, can solve the problems of high wood loss, high energy consumption, low pressing efficiency, etc., and achieve the effect of improving the extrusion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

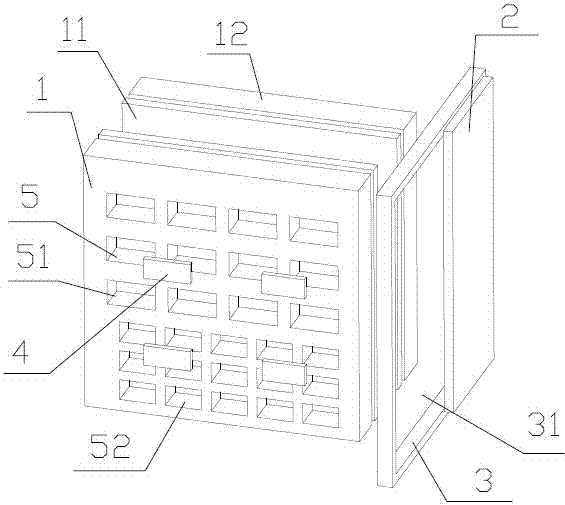

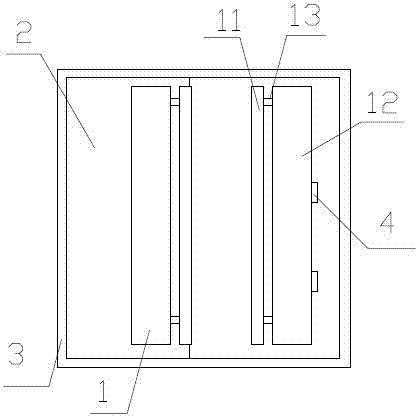

[0026] Example 1, such as figure 1 and figure 2 Shown: a pressure plate suitable for a pre-compression feeder, including a side pressure plate 1 and a front baffle 2, both of the side pressure plate 1 and the front baffle 2 extend in the vertical direction, and the side pressure plate 1 and the front baffle The plane where 2 is located is vertical, and the side pressure plate 1 includes an extrusion plate 11 for directly contacting with the wood to complete the extrusion action, a force plate 12 for connecting the transmission parts, and an elastic connection connecting the extrusion plate 11 and the force plate 12 13, the thickness of the force plate 12 is greater than that of the extruding plate 11, and the side of the extruding plate 11 used for extruding is a flat surface. The side pressure plate 1 and the front baffle 2 form a squeeze space, the user puts the wood in, the side pressure plate 1 squeezes the wood from the side, and the wood is blocked by the front baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com