Carving machine worktable

A workbench and engraving machine technology, applied in engraving, processing models, decorative arts, etc., can solve the problems of inconvenient movement, difficult operation, and inability to process workpieces multiple times, so as to facilitate subsequent operations, expand operating area, and facilitate movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0023] The invention will be described in detail below with reference to the accompanying drawings and examples.

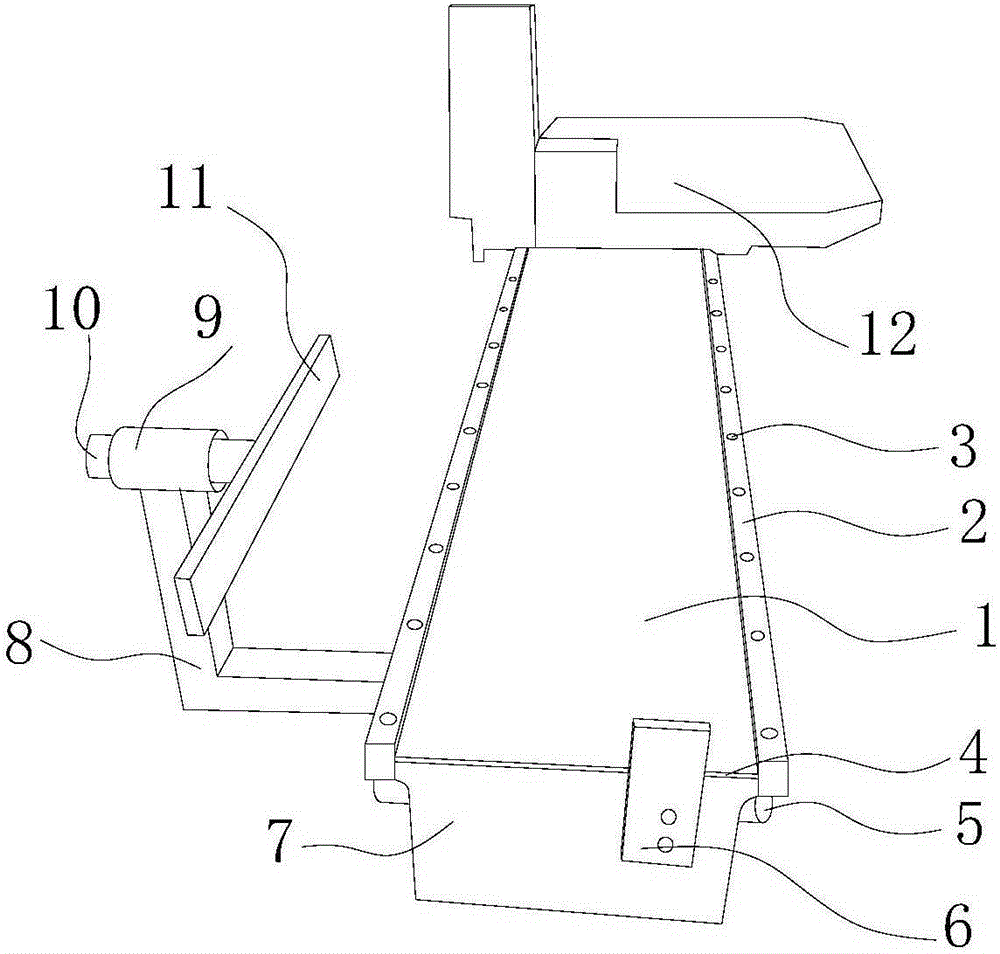

[0024] A workbench for an engraving machine, including an operation table 12, a transmission base 7, a conveyor belt 1 and a pusher plate 11, the transmission base 7 and the conveyor belt 1 are arranged on the side of the operation table 12, and the height of the conveyor belt 1 is slightly lower than The table top of the console 12, the conveyor belt 1 is arranged on the upper part of the transmission base 7, the conveyor belt 1 is driven to rotate by the roller 5 and the motor, the side of the conveyor belt 1 is limited by the closed side guard plate 2, and the safety frame 4 Set at the transmission end of the conveyor belt 1, the transmission end of the conveyor belt 1 is also provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com