Ocean engineering crane test bench

A technology of marine engineering and cranes, which is applied in the field of test benches, can solve the problems that the height of the test bench cannot be adjusted, the operating space is limited, and the simulation progress is affected, and the effect of simple adjustment, simple height, and improved use efficiency can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

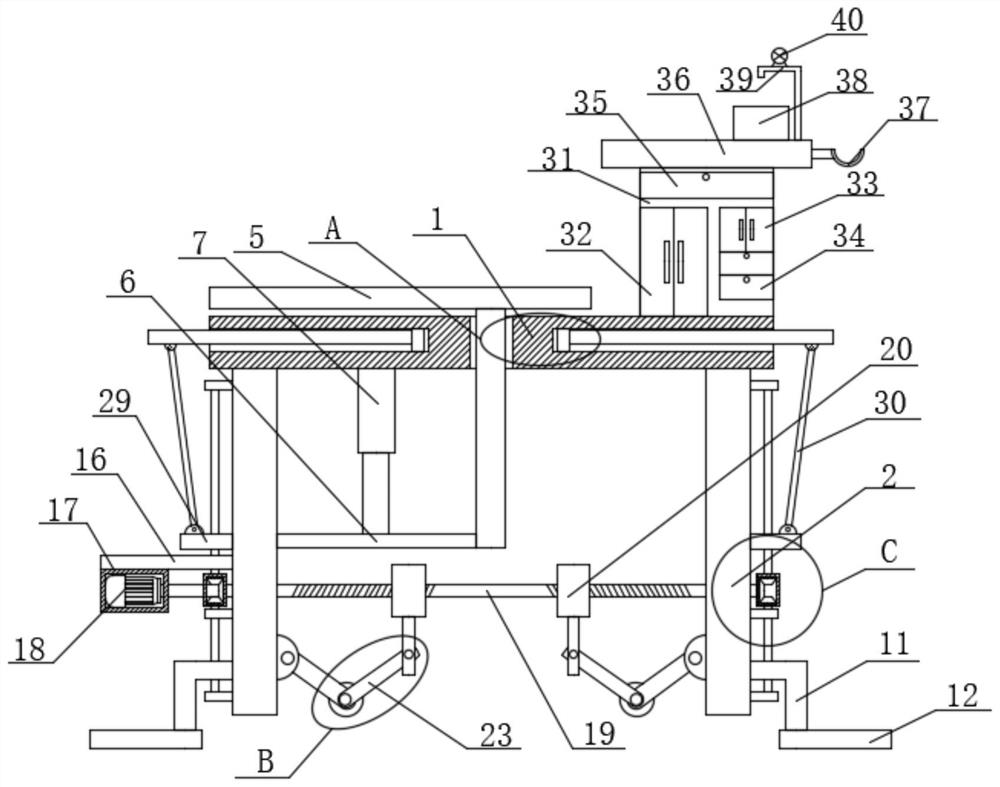

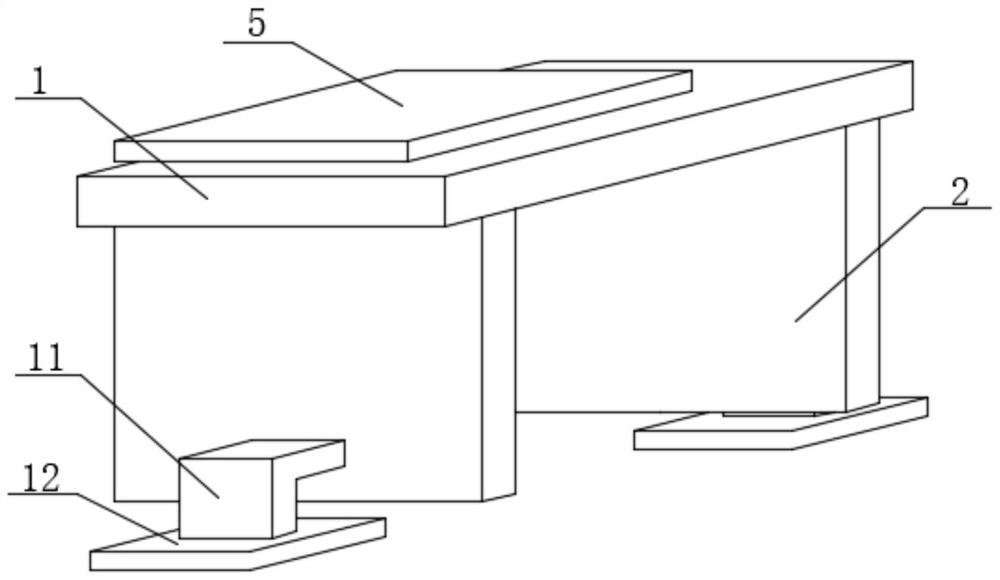

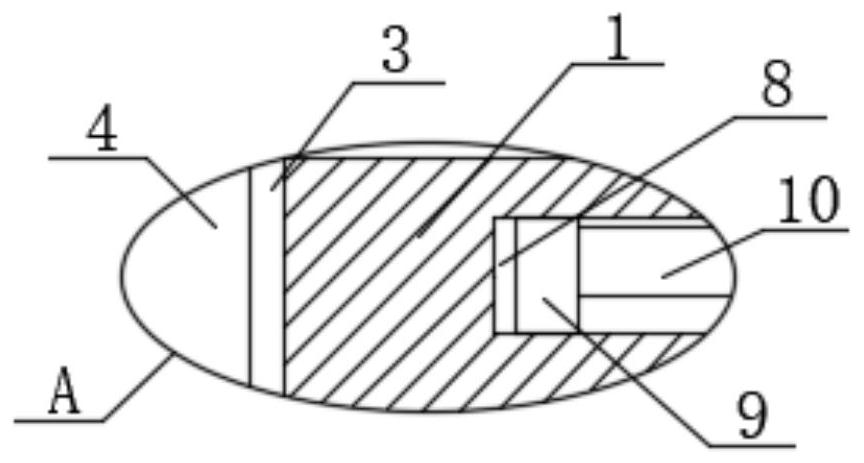

[0028] refer to Figure 1-5 , a marine engineering crane test bench, comprising a mounting plate 1, two vertical plates 2 are symmetrically and fixedly installed on the bottom of the mounting plate 1, a placement plate 5 is slidably mounted on the mounting plate 1, and an adjusting device is fixedly installed on the bottom of the mounting plate 1 , the two vertical boards 2 are slidably installed with support devices, the two vertical boards 2 are movably installed with moving devices, the two vertical boards 2 are slidably installed with push devices, and the two vertical boards 2 are slidably installed with two auxiliary boards 10 , the pushing device is movably connected with the two auxiliary boards 10, a driving motor 18 is fixedly installed on one of the two vertical boards 2, and a first screw rod 19 is fixedly installed on the output of the driving motor 18, and a first screw rod 19 is fixedly installed on the first screw rod 19. Two movable blocks 20 are installed on ...

Embodiment 2

[0040] refer to Figure 1-5 , a marine engineering crane test bench, comprising a mounting plate 1, two vertical plates 2 are symmetrically and fixedly installed on the bottom of the mounting plate 1, a placement plate 5 is slidably mounted on the mounting plate 1, and an adjusting device is fixedly installed on the bottom of the mounting plate 1 , the two vertical boards 2 are slidably installed with support devices, the two vertical boards 2 are movably installed with moving devices, the two vertical boards 2 are slidably installed with push devices, and the two vertical boards 2 are slidably installed with two auxiliary boards 10 , the pushing device is movably connected with the two auxiliary boards 10, a driving motor 18 is fixedly installed on one of the two vertical boards 2, and a first screw rod 19 is fixedly installed on the output of the driving motor 18, and a first screw rod 19 is fixedly installed on the first screw rod 19. Two movable blocks 20 are installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com