Wiring method for main line rail and return cable of new subway traction power supply line system

A main line rail and return cable technology, applied in power lines, power rails, transportation and packaging, etc., can solve the problems of increasing hidden trouble spots, unreasonable connection schemes between return cables and rails, and adding intermediate conversion links, etc. The effect of promoting application value, improving security and stability, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

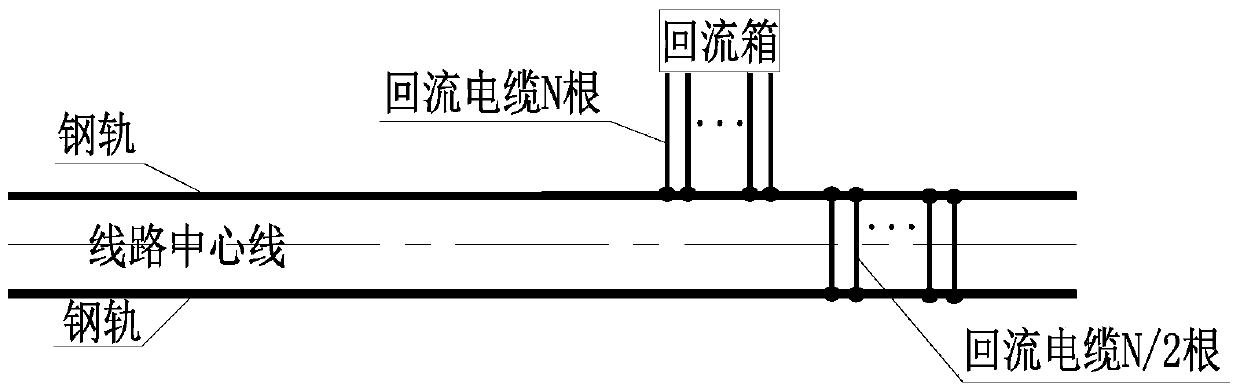

[0029] Such as image 3 In the connection and wiring method between the return cable and the rail (1), the connection method between the main line rail and the return cable of the new subway traction power supply line system, the specific steps are as follows:

[0030] (1) Lead out N flexible cables from the reflow box;

[0031] (2) Weld N / 2 flexible cables drawn from the reflow box directly to the adjacent rail;

[0032] (3) Weld the remaining N / 2 flexible cables drawn out to another rail through the embedded protective tube on the ballast bed;

[0033] The pre-embedded protective pipe in the above method is arranged inside the ballast bed, which avoids the damage of cables during rail construction and maintenance;

[0034] The material of the embedded protection pipe is glass steel pipe or galvanized steel pipe;

[0035] The diameter of the embedded protective tube is >1.3 times the diameter of the cable, which is determined according to the specific project.

Embodiment 2

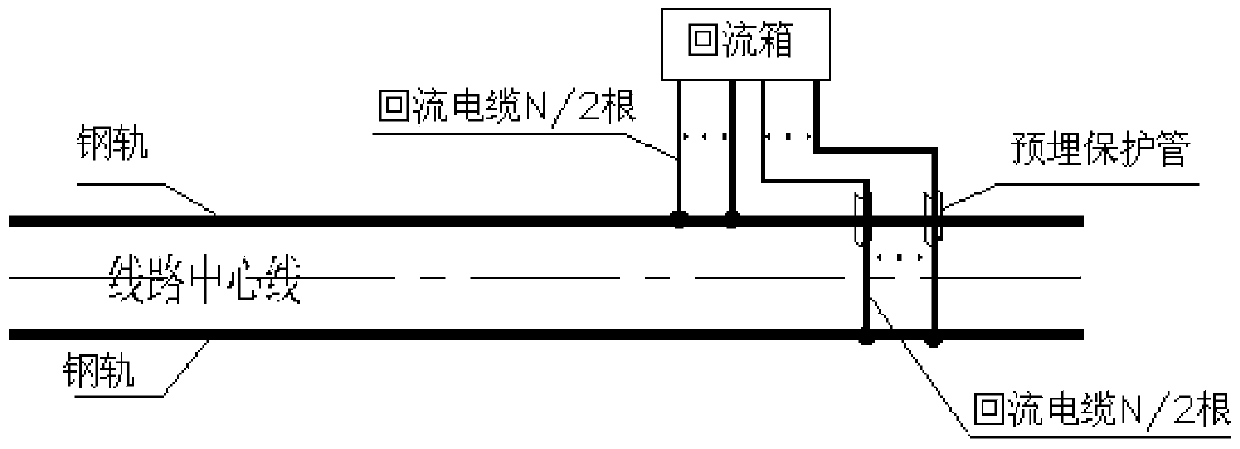

[0037] Such as Figure 5 In the connection and wiring method (2) between the return cable and the rail shown, the specific steps for the connection method between the main line rail and the return cable of the new subway traction power supply line system are as follows:

[0038] (1) Lead out N flexible cables from the reflow box;

[0039] (2) Take the N / 2 flexible cables drawn from the return box, place N / 2 flexible cables in the embedded protection tube, and lead them out to the side of the rail near the center line of the line through the lower part of the ballast bed welding;

[0040] (3) Weld the remaining N / 2 flexible cables drawn out to another rail through the embedded protective tube on the ballast bed;

[0041] The pre-embedded protective pipe in the above method is arranged inside the ballast bed, which avoids the damage of cables during rail construction and maintenance;

[0042] The material of the embedded protection pipe is glass steel pipe or galvanized steel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap