Method for controlling material filling

A control method and material technology, applied in packaging and other directions, can solve the problem of material scattering and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

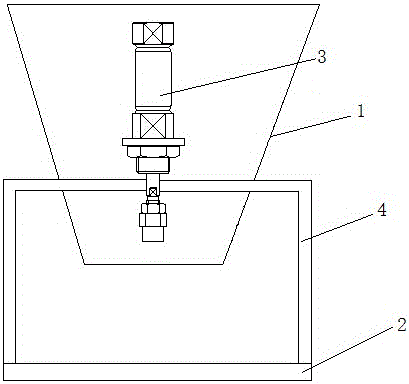

[0010] See figure 1 , a control method for material filling. First, the packaging bag is placed on the bag support plate 2, and then the cylinder 3 is controlled. The cylinder 3 drives the bag support plate 2 to move up through the L-shaped connecting rod 4 until the weighing bucket 1 The position sensor at the discharge port detects the opening of the packaging bag, and then the controller controls the cylinder 3 to stop moving, the positioning of the bag support plate 2 is completed, and then the discharge valve at the discharge port of the weighing hopper 1 is opened, and the material is filled wherein, the end of the L-shaped connecting rod 4 horizontal part is connected with the piston rod of the cylinder 3, and the end of the vertical part is fixedly connected with the support plate 2 of the supporting bag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com