A kind of culture bottle transport packaging device and packaging method

A packaging method and culture bottle technology, which are applied in the directions of transportation and packaging, packaging, packaging of fragile items, etc., can solve the problems of the culture bottle being easily broken, and achieve the effects of small vibration amplitude, preventing rupture and increasing transportation volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

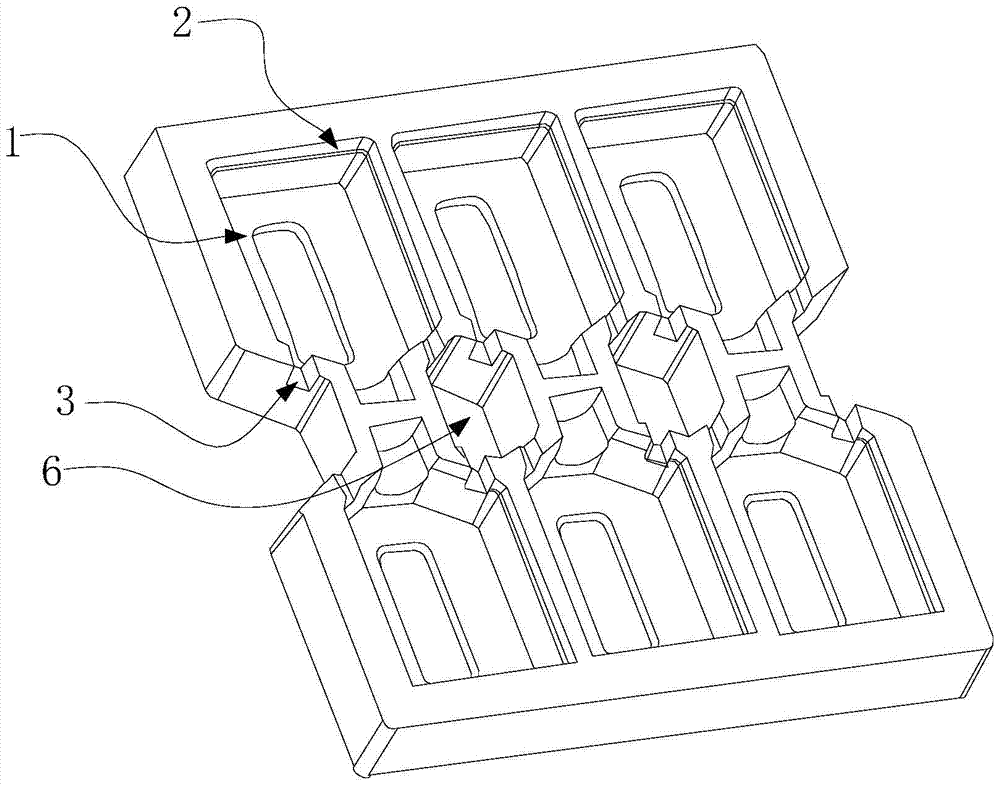

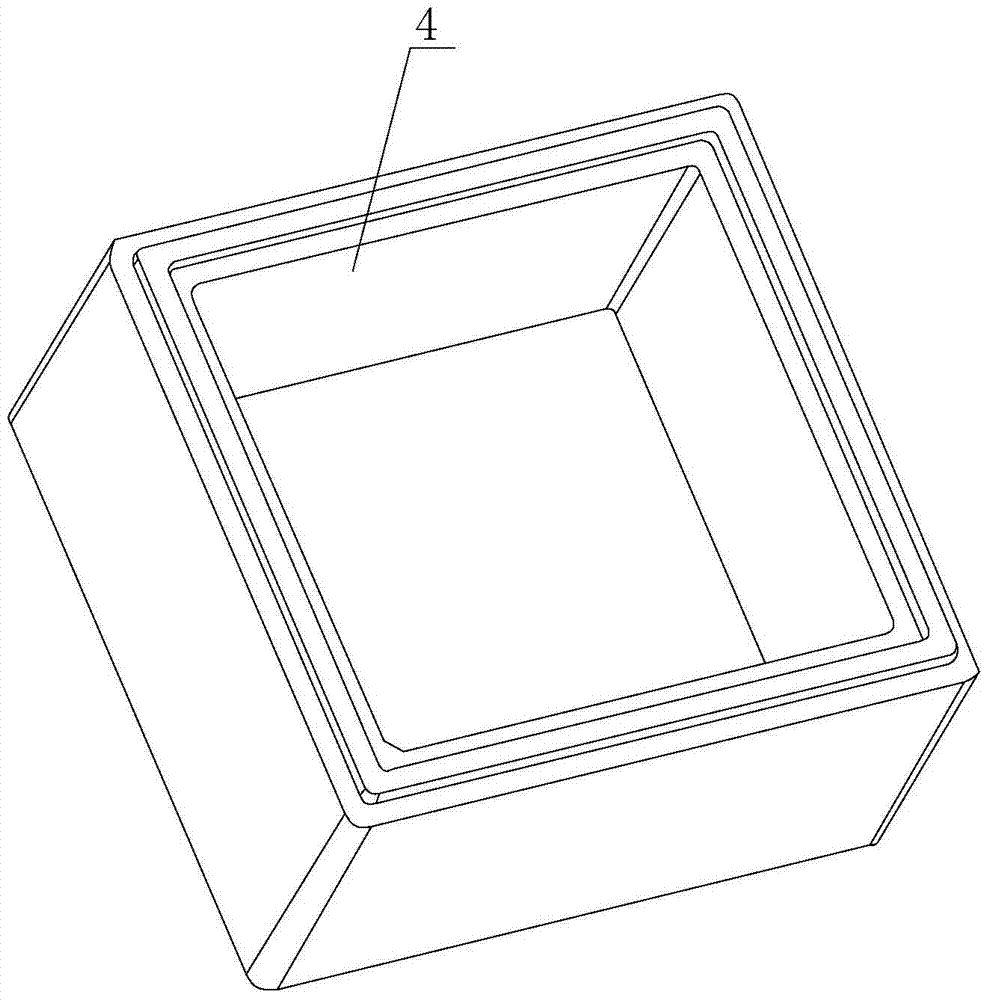

[0029] A transport and packaging device for culture bottles, comprising a box body 4 and a box cover 5, and a plurality of storage boxes are arranged in the box body 4. The storage frame includes a front, a rear and various sides, and a plurality of evenly distributed storage chambers 1 are arranged on the front and rear of the storage frame, the storage chamber 1 at the front and the storage chamber 1 at the rear one by one correspond. The storage chambers are symmetrically distributed in two rows on two planes, and each row has 3 storage chambers. The storage chamber 1 is compatible with the culture bottle. The box body 4 is divided by a plurality of partitions into a plurality of cavities for storing storage frames, and each cavity can place a storage frame.

[0030] For the aforementioned transport and packaging device for culture bottles, firstly, the user places the culture bottle containing the culture solution in the storage chamber 1; then, the storage frames are se...

Embodiment 2

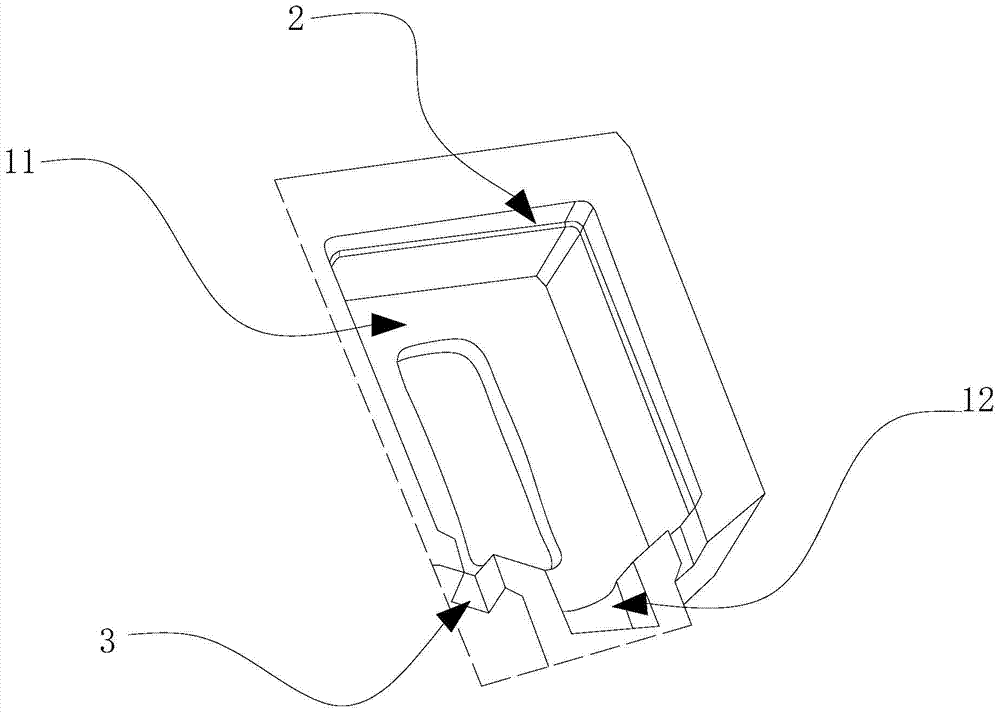

[0032] A culture bottle transportation and packaging device, comprising a box body 4 and a box cover 5, a plurality of storage boxes are arranged in the box body 4, and a plurality of evenly distributed storage chambers 1 are arranged on the storage box, and the storage chambers 1 Compatible with culture flasks. The storage chambers are located on one of the planes of the storage frame, and each storage chamber 1 includes a main chamber body 11 and a bottle mouth placement table 12 integrated with the main chamber body 11 . The storage chambers 1 are symmetrically distributed in two rows, and each row has three storage chambers. The bottle mouth placement platform 12 of the first storage chamber 1 and the bottle mouth placement platform 12 of the second storage chamber 1 are relatively distributed and both are located in the middle of the storage frame. Through-holes 6 are arranged between any adjacent four bottle mouth placement platforms 12 ; ventilation grooves 3 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com