Method for reconstructing temporary diversion tunnel into permanent flood discharge facility

A diversion tunnel, permanent technology, applied in construction, hydroelectric power station, marine engineering and other directions, can solve problems such as damage, wear and tear of the overflow wall, submerged cave roof, etc., achieve flexible inlet elevation layout, prolong service life, Improve the effect of energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

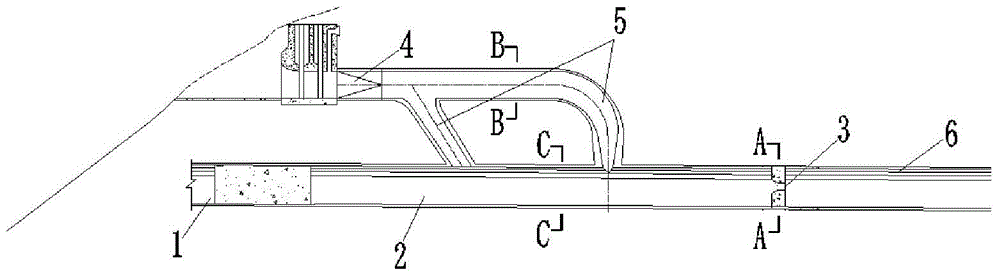

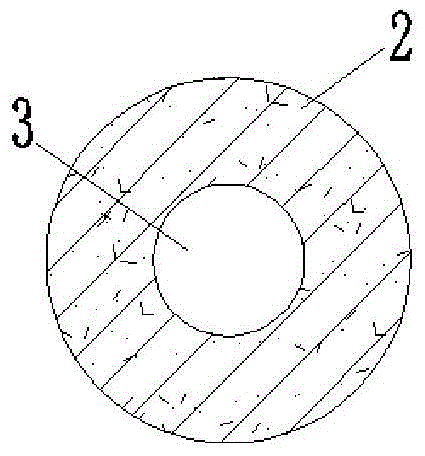

[0028] Such as figure 1 As shown, firstly, the entrance of the original diversion tunnel 1 is blocked, and then the turning section of the entrance and the subsequent straight section 5 times the height of the tunnel are rebuilt into the energy dissipation pressure forebay 2, and the wall surface at the end of the energy dissipation pressure forebay 2 One is set to face the empty jet outlet 3 on all sides, and the section of the jet outlet is circular, see figure 2 , and make the original diversion tunnel section after the jet outlet 3 become the open flow section 6 of the permanent flood discharge tunnel.

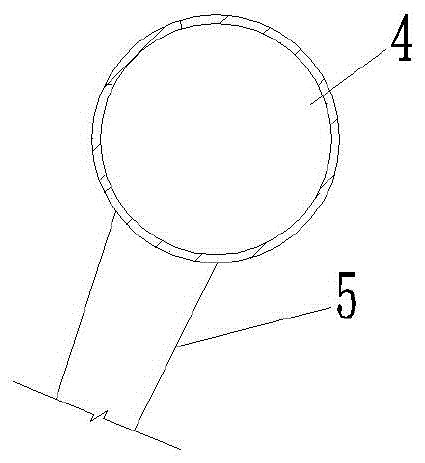

[0029] In this embodiment, a pressurized flood discharge tunnel 4 is newly built at the position above the entrance of the original diversion tunnel 1 that was blocked, and its cross-sectional shape is circular, see image 3 , and the cross-sectional area is smaller than the cross-sectional area of the original diversion tunnel 1, and the bottom elevation of the entran...

Embodiment 2

[0031] Such as Figure 5 , 6 As shown, the entrance of the original diversion tunnel 1 is first blocked, and then the turning section of the entrance and the straight section 7 times the height of the tunnel are rebuilt into the energy dissipation pressure forebay 2, which is in the shape of a city gate. , so a four-sided empty jet outlet 3 is set on the wall of the end, the section of the jet outlet is rectangular, see Figure 7 , and make the original diversion tunnel section after the jet outlet 3 become the open flow section 6 of the permanent flood discharge tunnel.

[0032] In this embodiment, two pressurized flood discharge tunnels 4 are newly built above the entrance of the blocked original diversion tunnel 1, and the entrances of each flood discharge tunnel are arranged along the elevation ladder, and the cross-sectional shape is a city gate shape, see Figure 8 , and the cross-sectional area is smaller than the cross-sectional area of the original diversion tunne...

Embodiment 3

[0034] The difference between the method of rebuilding the temporary diversion tunnel into a permanent flood discharge facility described in this embodiment and embodiment 2 is that: 1) the newly-built flood discharge tunnel 4 is 4, and the entrances of each flood discharge tunnel 4 are arranged along the elevation ladder, Such as Figure 11 2) The connecting pipes 5 are all formed directly after turning at the end of the newly built flood discharge tunnel 4; 3) The total area of the connection between the four connecting pipes 5 and the energy dissipation pressure forebay 2 is equal to the cross-sectional area of the original diversion tunnel 1 ; 4) The two connecting pipes 5 located upstream of the energy dissipation pressure forebay 2 are connected with the top surface of the energy dissipation pressure forebay 2 by the axis, and the two connecting pipes 5 located downstream of the energy dissipation pressure forebay 2 are connected to the energy dissipation pressure for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com