Automatic closing structure of water inlet valve of closestool

An automatic shut-off and water inlet valve technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve problems such as toilet blockage, flush toilet overflow, toilet flush valve leakage, etc., and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

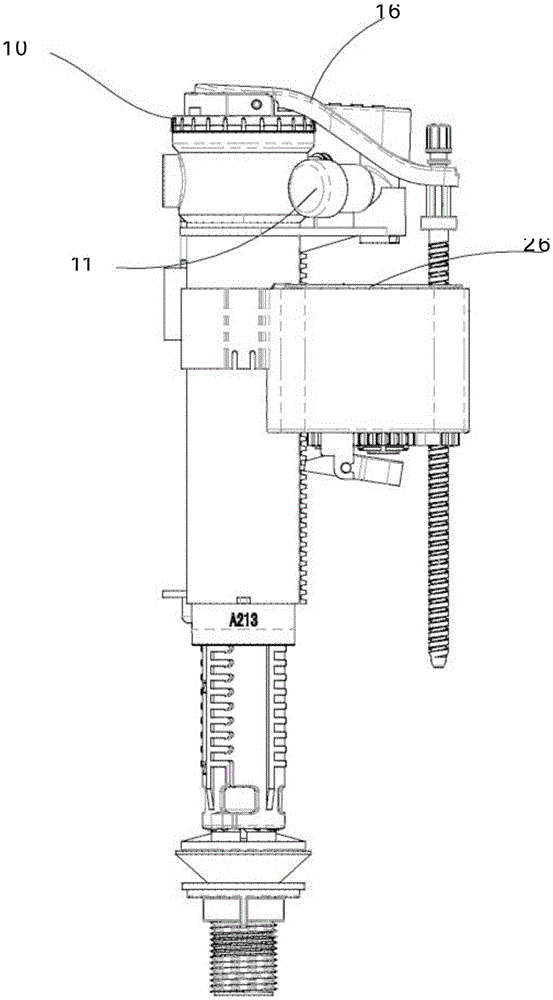

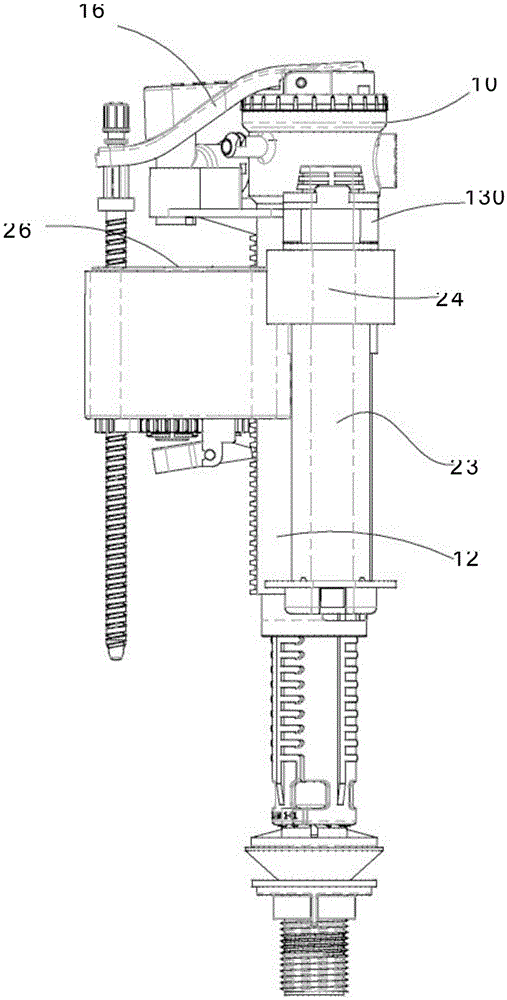

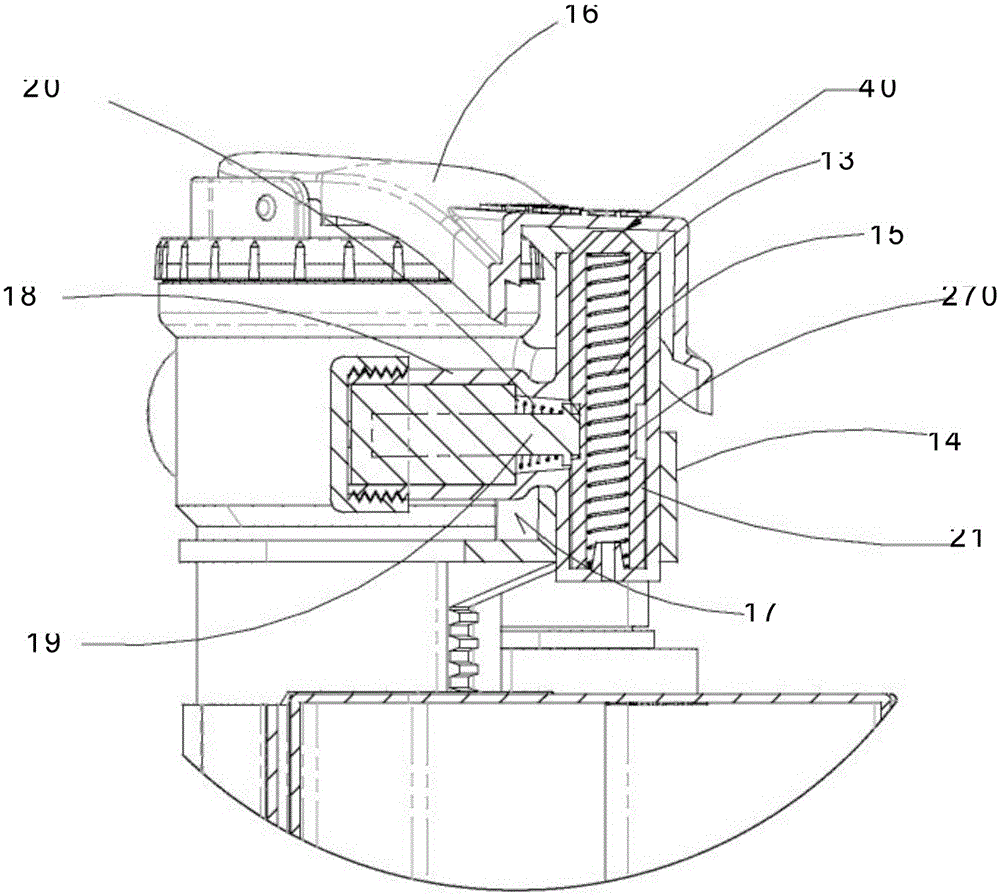

[0045] Example 1: Please see Figure 1-7 , A toilet water inlet valve automatic closing structure, with a water inlet valve floating ball structure 26 that raises the floating arm 16 to correspond to the rising water level 8 of the toilet tank 9. The floating arm 16 uses the water inlet valve floating ball structure 26 Lift up to close the toilet inlet valve 10; also includes:

[0046] An auxiliary transmission device 11, the auxiliary transmission device 11 includes a slidable piston 13 perpendicular to the bottom of the floating arm 16, when the piston 13 is in the rising position 50, the floating arm 16 is lifted to fully close the toilet inlet valve 10 ; An eccentric device 15 pushes the piston 13 up to the rising position 50.

[0047] A solenoid structure 18 is usually in a de-energized state, and when the piston 13 is in the lowered position 40, it slidingly engages the locking structure 17 of the piston 13; when energized, the solenoid structure 18 is released from the locki...

Embodiment 2

[0058] Embodiment 2: In this embodiment, except for the eccentric device 15, the rest is basically the same as the above embodiment, so it will not be repeated.

[0059] See Figure 8-9 The eccentric device 15 is a hydraulic structure 200 driven by the water pressure of the toilet inlet valve 10. In this embodiment, the solenoid control valve 210 is usually in a de-energized state, so as to appropriately block the water pressure of the toilet water inlet valve 10 caused by the lifting of the piston 13, so as to facilitate closing the toilet water inlet valve 10. The solenoid structure 211 is a push type instead of the pull type shown in the above embodiment. Both types can be used. The solenoid 211 and the valve core 214 block the toilet inlet valve 10 in its normal position when the power is turned off. The water pressure of the hole 213 can be obtained through the hose 215 from the toilet water inlet valve 10 or other water channels connected to the inlet of the toilet water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com