A Self-resetting Steel Coupling Beam System Using Shape Memory Alloy Tie Rods

A memory alloy, self-resetting technology, applied in the direction of joists, girders, trusses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

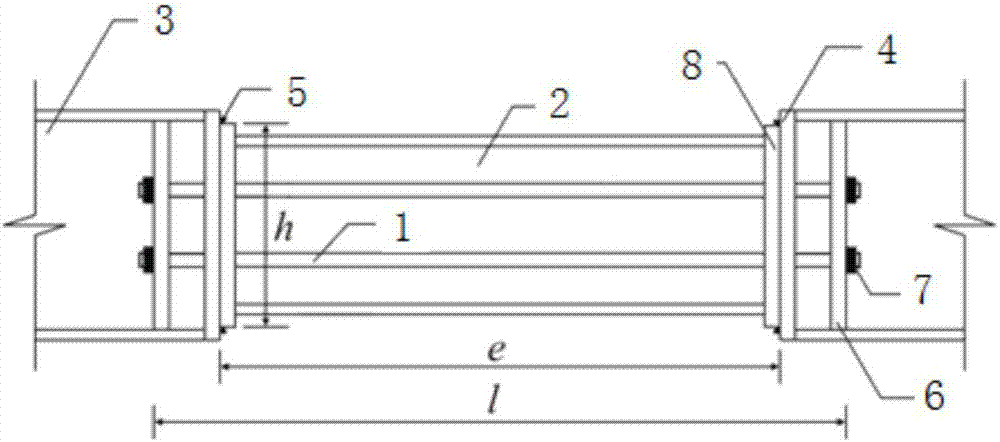

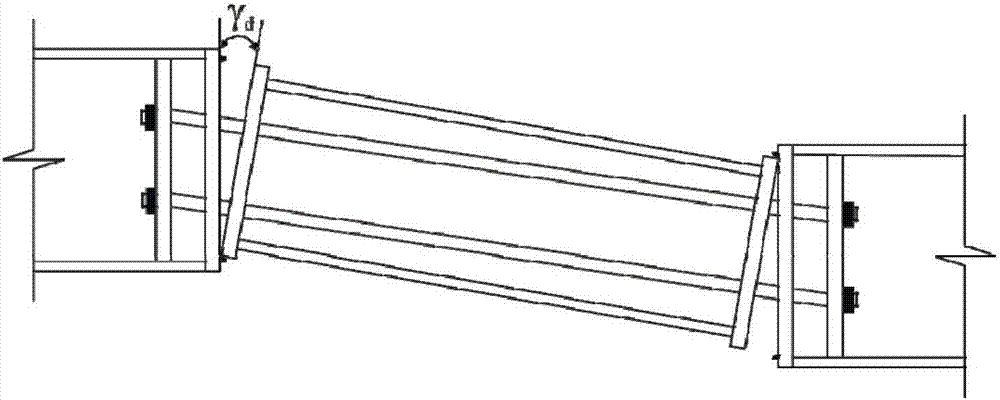

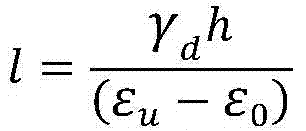

[0020] Such as figure 1 As shown, the present invention adopts a self-resetting steel connecting beam system using a shape memory alloy tie rod, which is composed of a steel connecting beam 2 and a shape memory alloy tie rod 1. In the meantime, the shape memory alloy tie rod 1 runs through the entire length of the steel connecting beam 2, and both ends are anchored to the main structural member 3 connected to the steel connecting beam 2.

[0021] The shape memory alloy tie rod 2 applies a pre-tension force before anchoring, and after anchoring, the pre-tension force will form a pre-compression between the steel connecting beam 2 and the main structural member 3 connected thereto. The two ends of the shape memory alloy tie rod 1 can be designed as threads, and the prestress can be applied by means of bolt fastening, or a special anchoring dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com