Spherical Automatic Centering Method Applied to Surface Defect Detection of Spherical Optical Components

A spherical optics, automatic centering technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems affecting the imaging quality of the optical system, secondary damage, energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

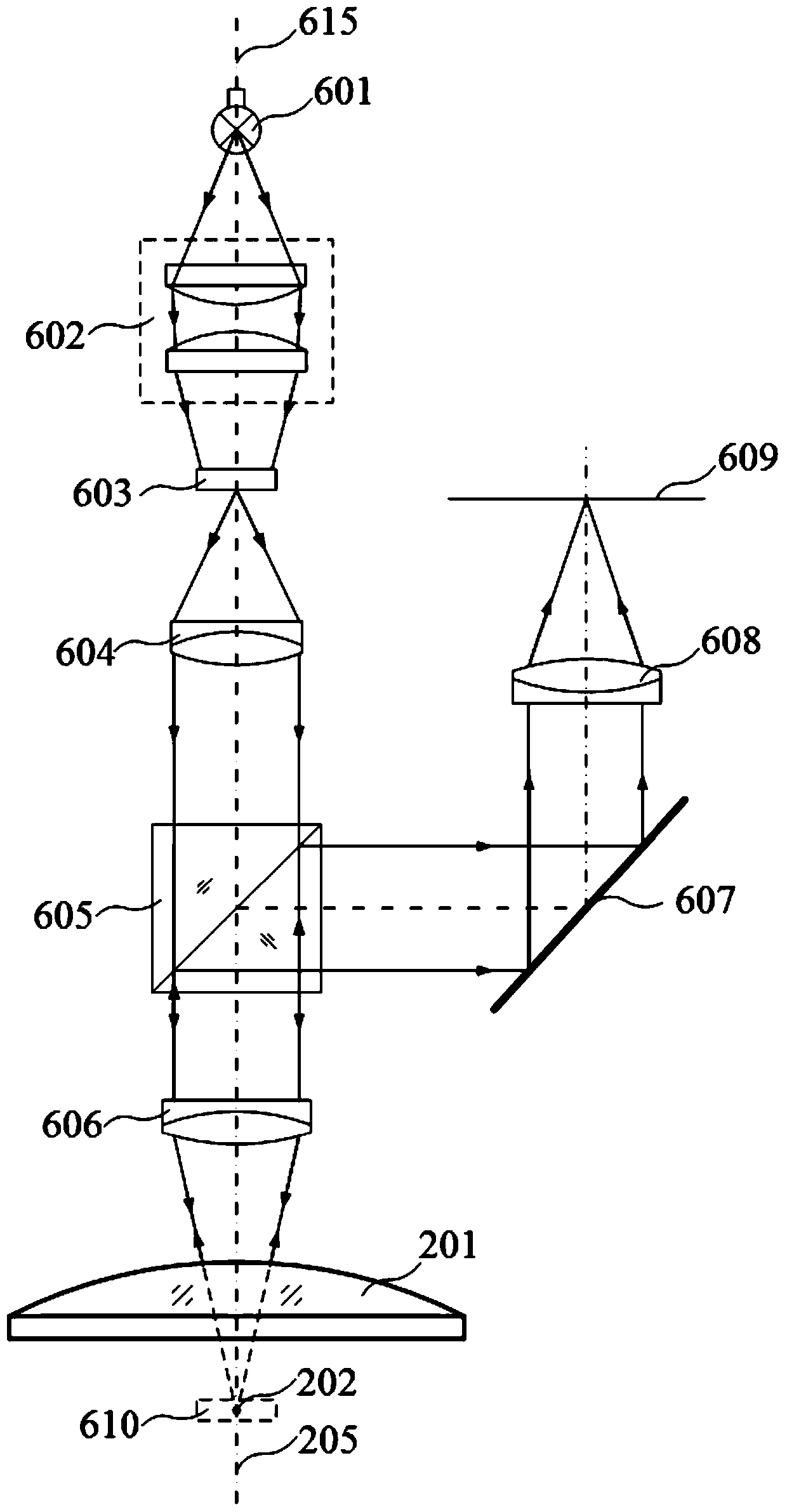

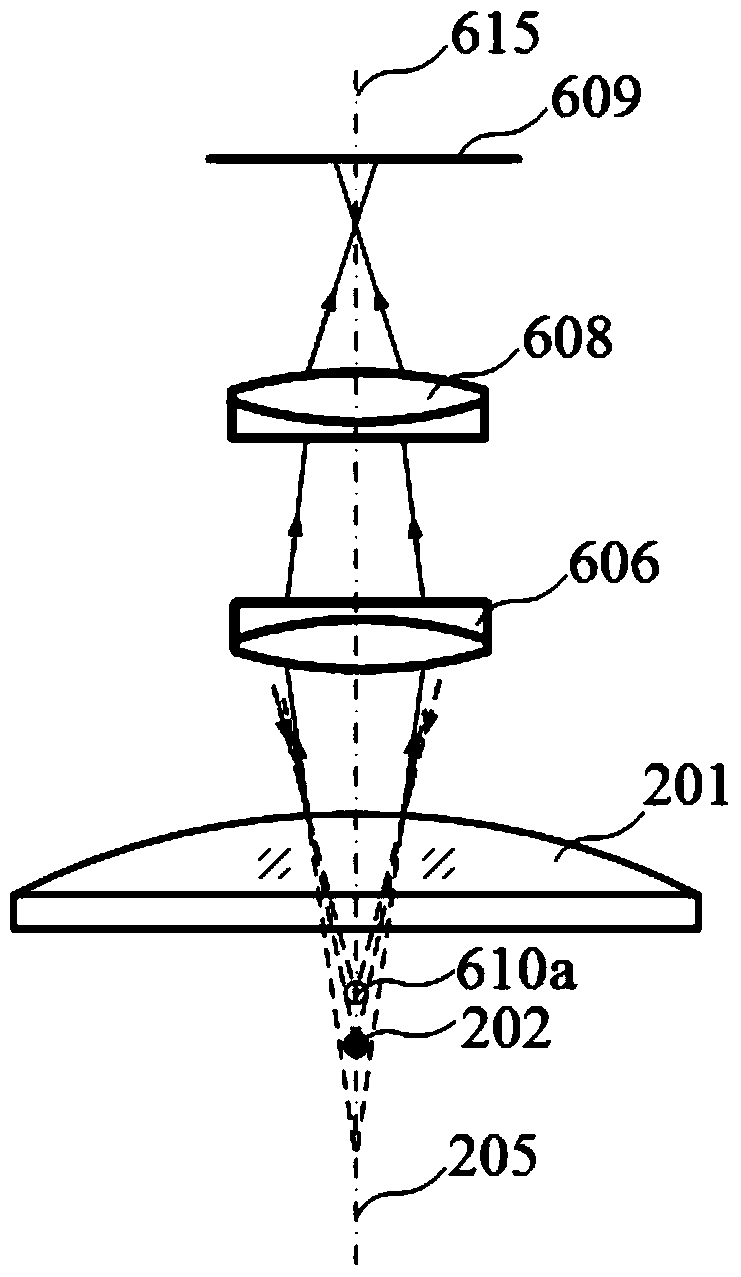

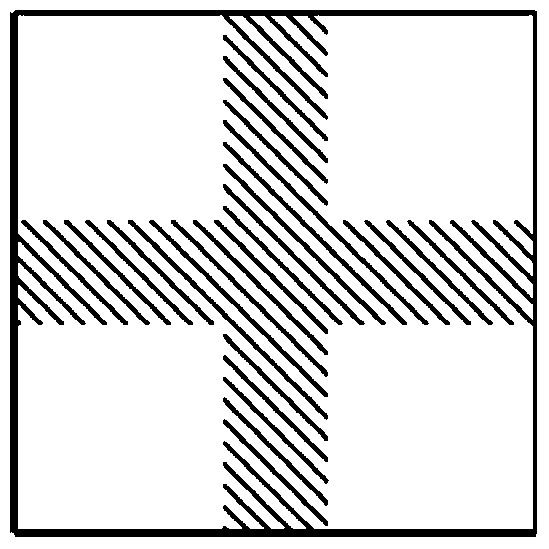

[0030] The spherical centering unit provides a hardware basis for completing the centering of the spherical optical element 201 . figure 1 Shown is the block diagram of the spherical centering unit. The spherical centering unit includes a light source, a light source focusing lens group, a reticle, a collimating lens, a beam splitter, an objective lens, a reflector, an imaging mirror and a CCD; the light emitted by the light source 601 in the spherical centering unit passes through the light source focusing lens group The reticle 602 is irradiated on the reticle 603, and the reticle 603 is engraved with a cross wire. After that, the light is transmitted through the collimating lens 604 and then enters the beam splitter 605. After being transmitted through the beam splitter 605, the light is irradiated on the spherical optical element 201 through the objective lens 606, and is reflected on its surface. At this time, the cross on the reticle 603 The image formed by the wire is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com