A design method of diamond glass indenter based on intensity factor

A technology of glass indenter and strength factor, which is applied in the direction of testing the hardness of materials, can solve the problems of not being able to give convincing design reasons, and achieve the effects of good wear resistance, long service life and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

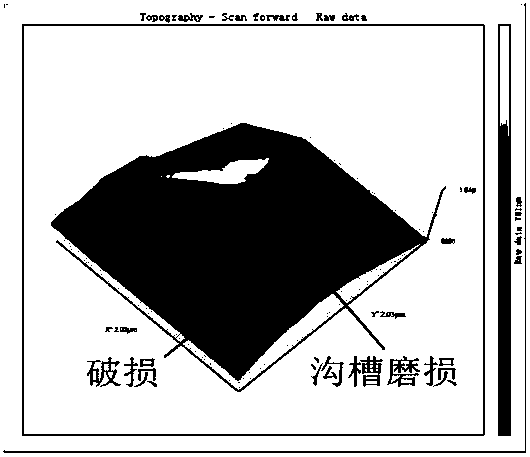

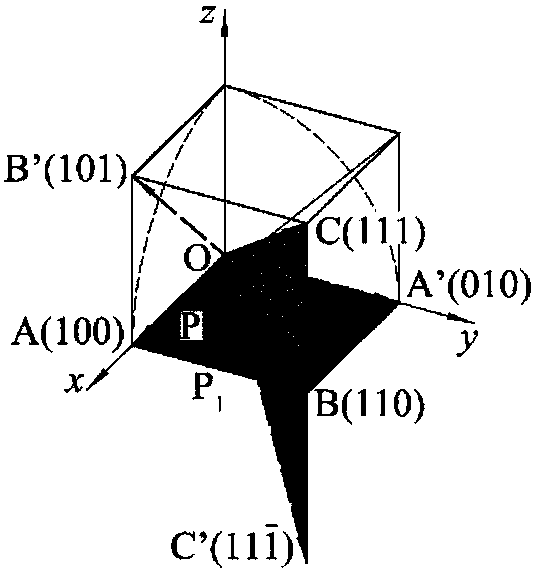

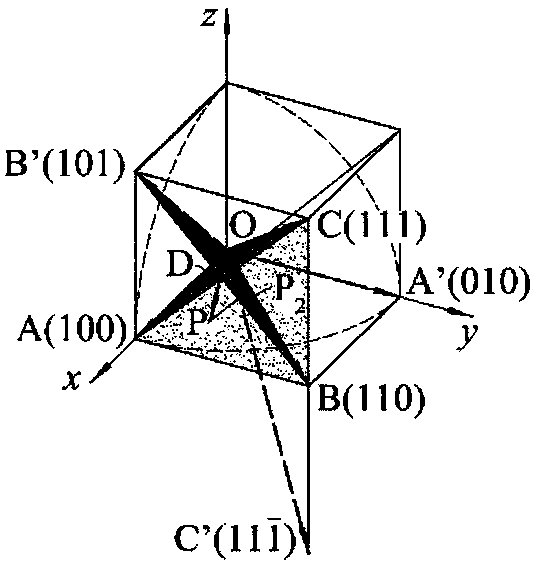

[0042] The invention provides a method for designing the crystal plane and crystal orientation of the side of the diamond glass indenter based on the intensity factor, which provides a scientific basis for the design of the diamond glass indenter. The radius of the blunt circle of the indenter optimized by the invention can reach Below 30nm, better than the technical index requirements of the international standard ISO14577, Figure 1-3 It is a schematic diagram of the superimposed influence of three typical crystal plane families on the characteristics of any crystal plane P. The specific implementation is as follows:

[0043] 1. Dynamic microscopic tensile strength of diamond crystal with any crystal plane and crystal orientation

[0044] According to the theory of dynamic microscopic tensile strength of diamond crystal and the principle of strength superposition, it is assumed that the dynamic microscopic tensile strength of any crystal plane of diamond crystal is the weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com