A camera module standard device and assembly method thereof

A camera module and standard device technology, applied in electrical components, image communication, color TV components, etc., can solve the problems of inability to standardize production, high material costs, etc., and achieve material saving, high yield and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, invention is described in further detail.

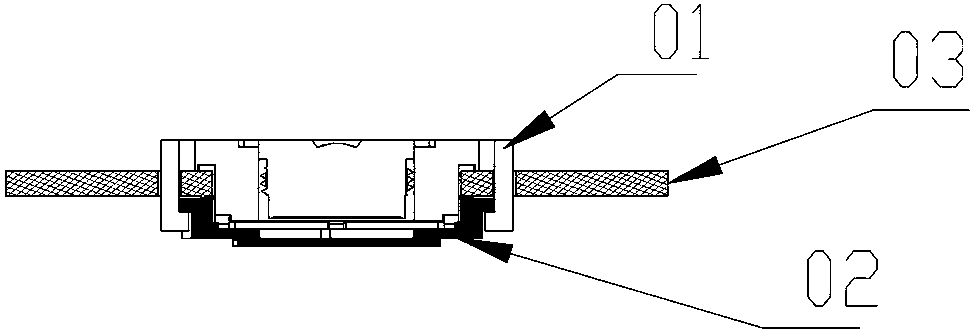

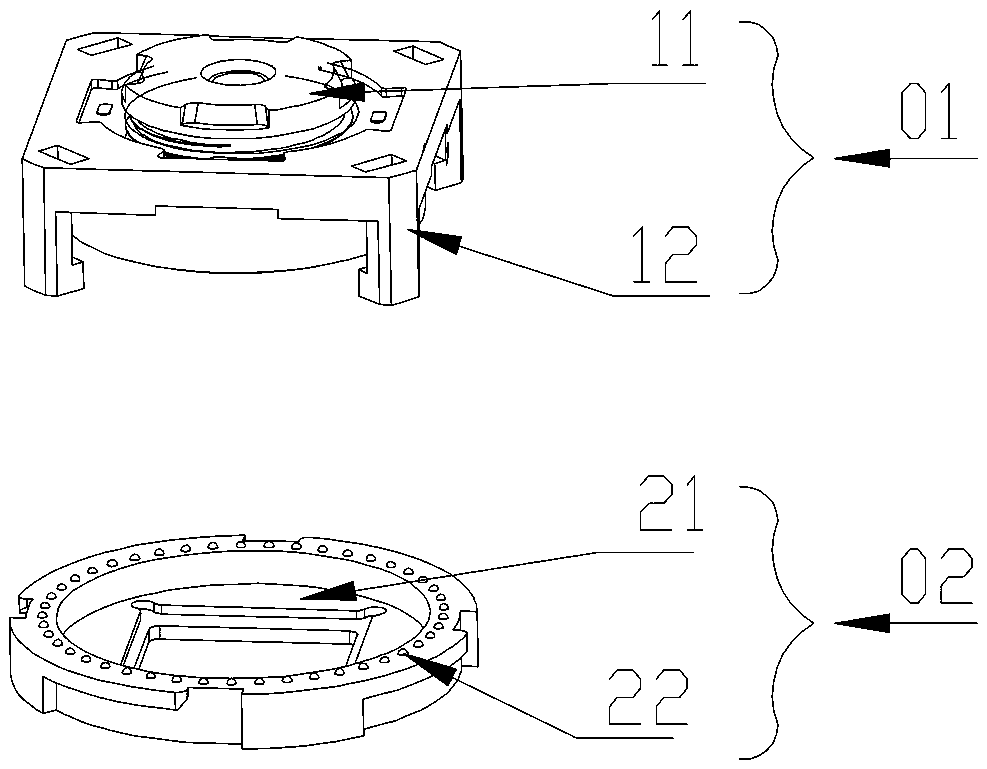

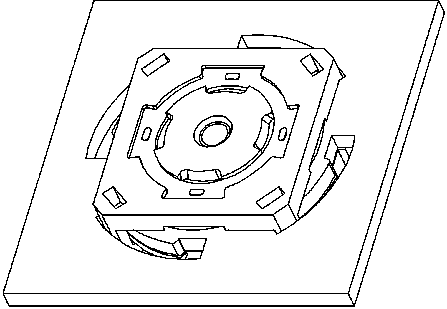

[0023] Such as figure 2 As shown, a camera module standard device includes a lens assembly 01 and a chip assembly 02; the lens assembly 01 includes a lens 11 and a lens holder 12; the chip assembly 02 includes a photosensitive chip 21 and a circular pad 22 . The lens 11 is connected to the lens holder 12 through threads. The photosensitive chip 21 and the circular pad 22 are connected by wafer bonding. The circular pad 22 has an annular metal pin and four annular relief holes, and the lens holder 12 has four male buckles. The lens assembly 01 and the chip assembly 02 are connected through the four male buckles of the lens holder 12 and the four annular relief holes of the circular pad 22 . The circular pad 22 is welded and attached to the main board of the digital product through the circular metal pin.

[0024] A camera module standard device assembly method, the specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com