Sorting machine for capsules

A sorting machine and capsule technology, applied in sorting and other directions, can solve the problems that the error rate cannot meet the requirements and the efficiency is difficult to further improve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

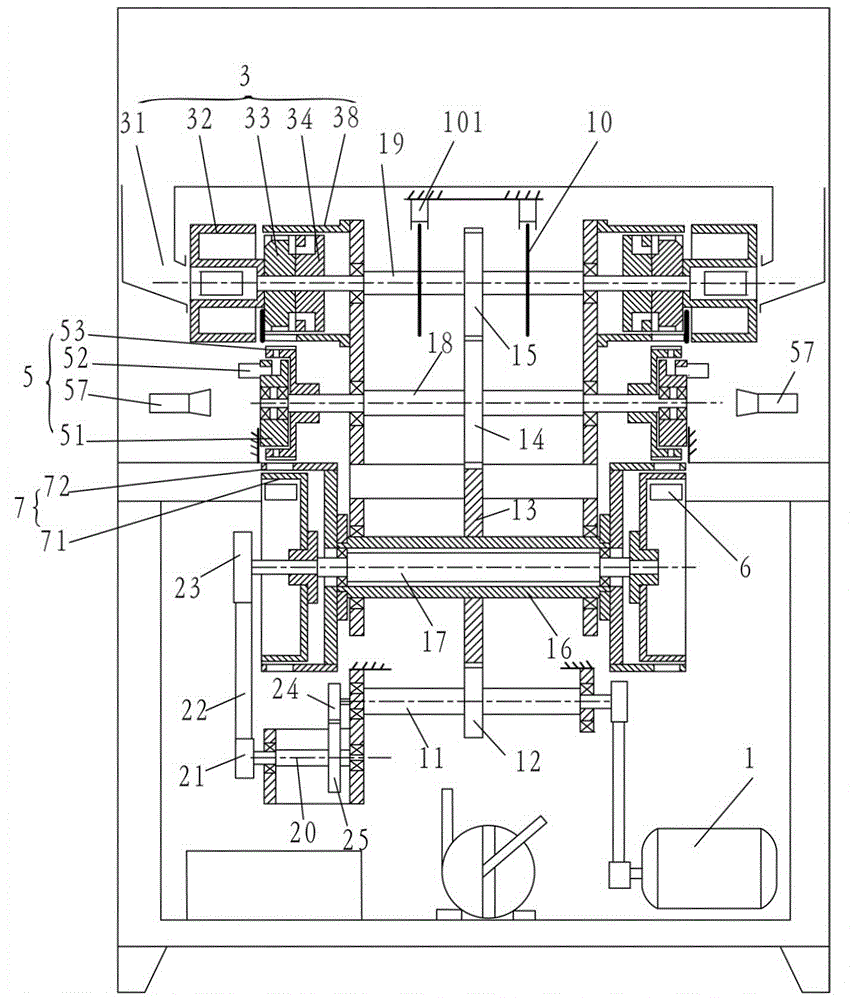

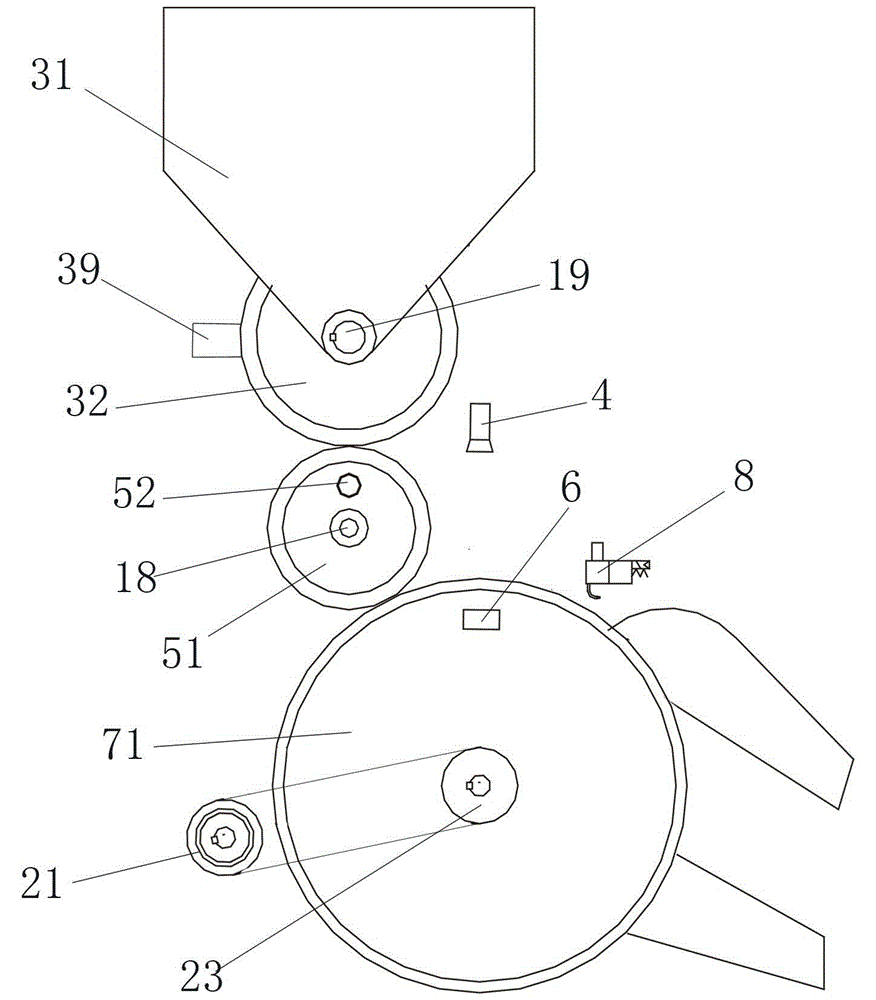

[0034] See attached picture. This embodiment is a complete sorting machine for defective capsules, including a feeding system 3 , an end surface photographing system 5 and a peripheral surface photographing system 7 . attached figure 1 The machine includes two sets of mutual symmetry, for the convenience of description, the present embodiment only describes one of them.

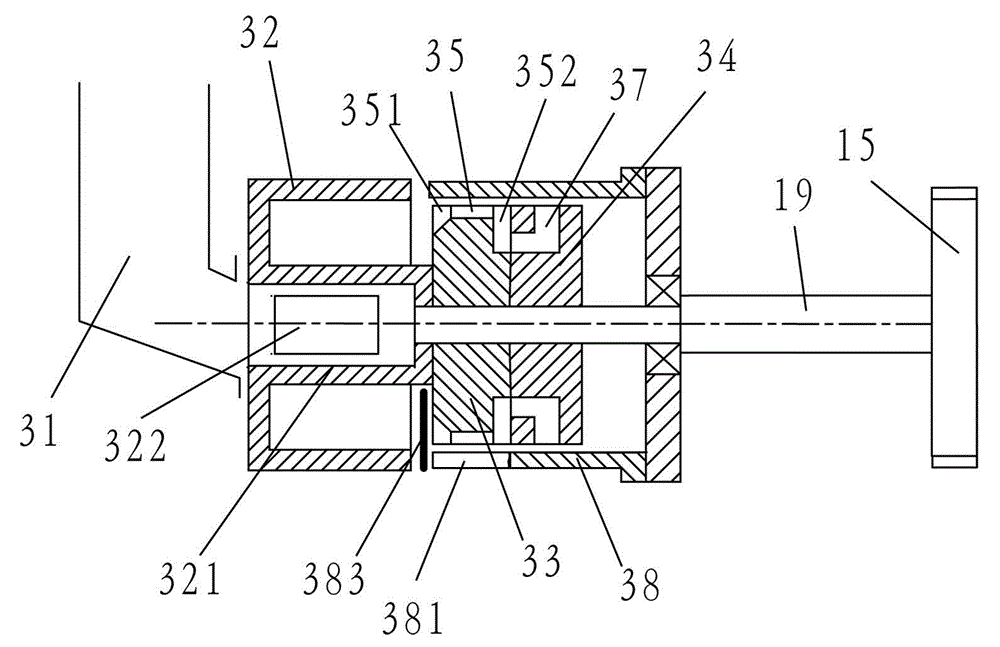

[0035] The feeding system 3 includes a feeding port 31, a storage wheel 32, a first feeding wheel 33, a first adsorption wheel 34 and a material protection wheel 38; the structure of the storage wheel 32 is an open cylinder with a cylindrical groove in the middle 321, the axial section is "concave"; the notch of the cylindrical groove 321 is connected to the feeding port 31, the bottom of the cylindrical groove 321 is provided with a shaft hole 324, and the side wall of the groove is provided with an opening 322; the storage wheel The inner wall of 32 is provided with a circle of tooth-shaped structure 323,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com