Scrap cleaning device of numerically controlled lathe

A technology of CNC lathes and cleaning devices, which is applied in the direction of auxiliary devices, turning equipment, tool holder accessories, etc., and can solve the problems of flying debris, being stuck and unable to open or close, and not being able to remove debris well. , to achieve the effect of comprehensive cleaning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

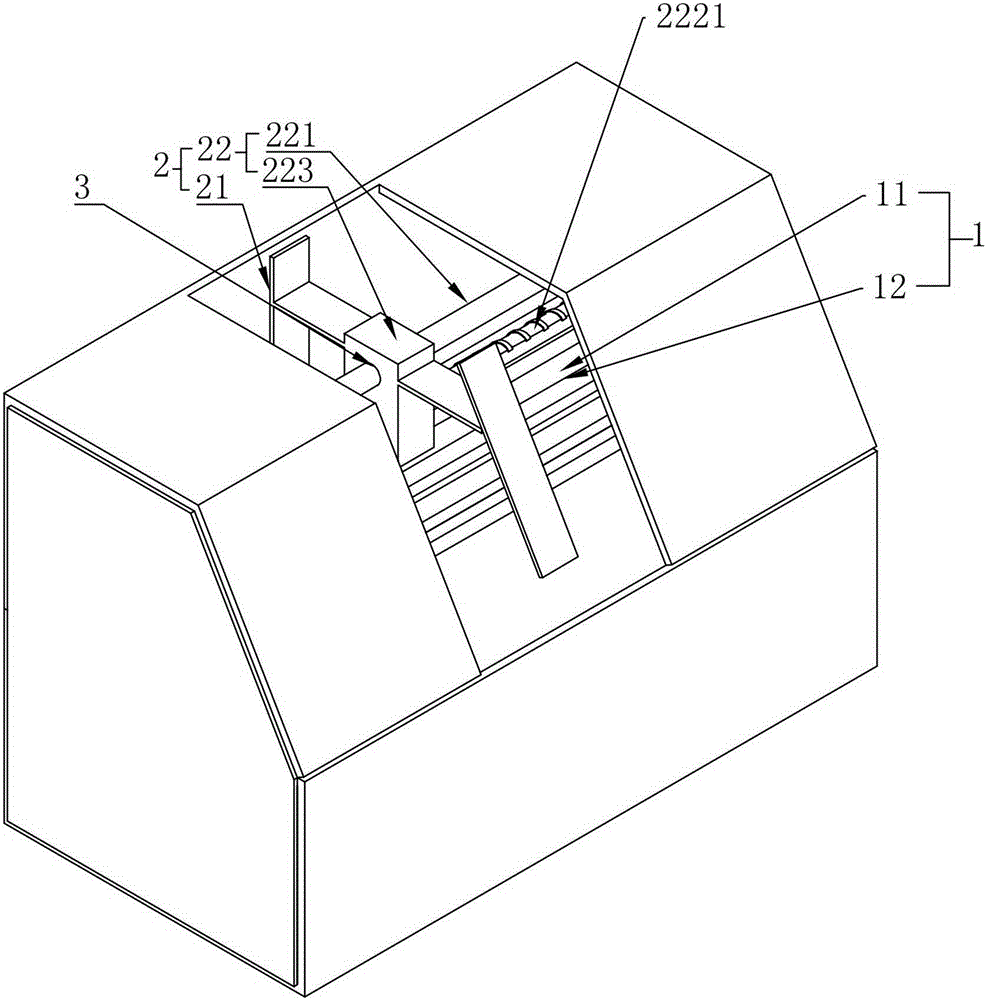

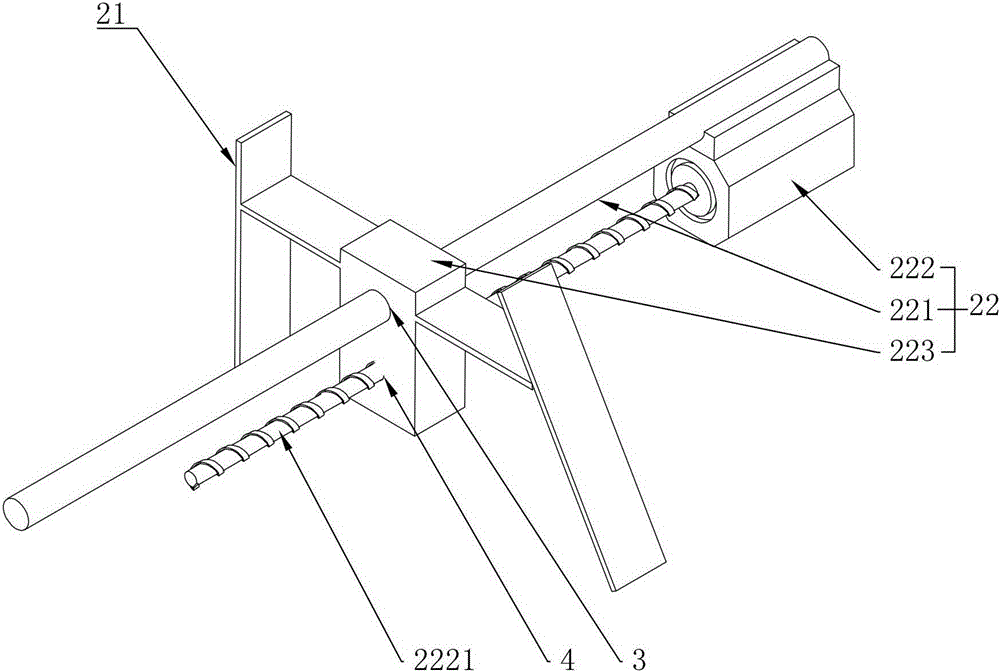

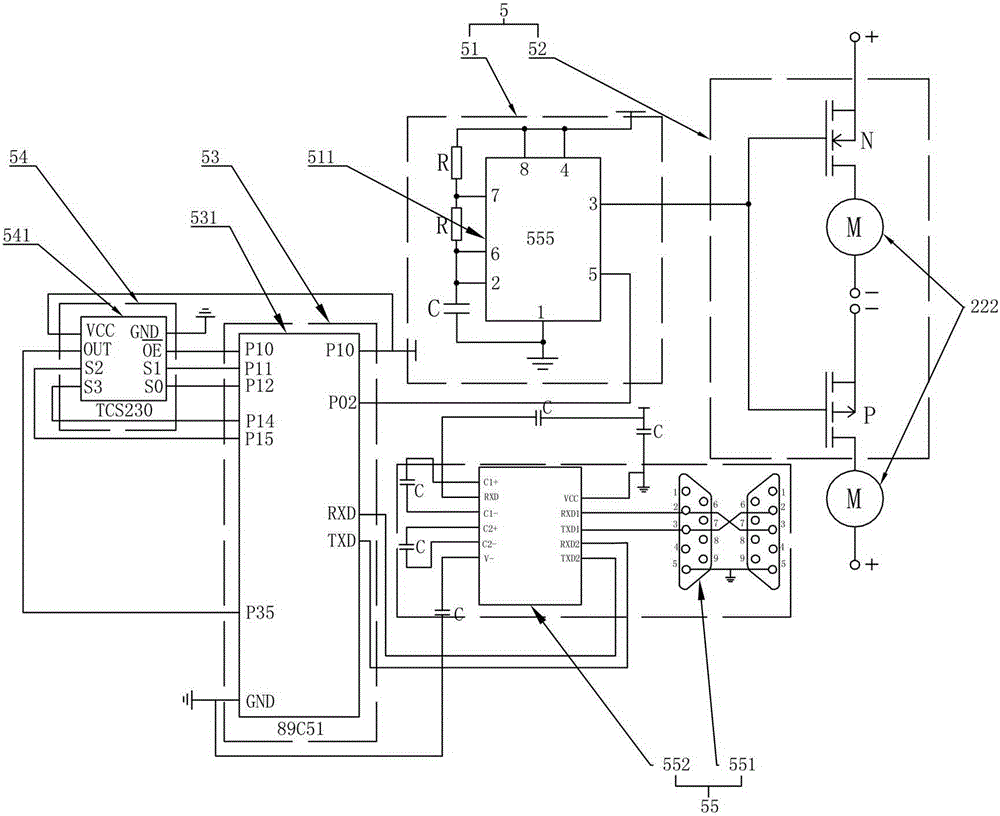

[0014] refer to figure 1 As shown, a waste chip cleaning device of a numerically controlled lathe in this embodiment includes a main chip removal mechanism 1 and an auxiliary chip removal mechanism 2, and the main chip removal mechanism 1 includes a mechanism for sending waste chips out of the waste chip cleaning device of a numerically controlled lathe. Conveyor belt 11 and chip discharge flute 12 for receiving waste chips, the conveyor belt 11 is used as the bottom of the chip discharge groove 12, the auxiliary chip removal mechanism 2 is arranged above the chip removal groove 12, and the auxiliary chip removal mechanism 2 It includes a scraper 21 attached to the frame shell of the waste cleaning device of a CNC lathe and a drive assembly 22 that drives the scraper 21 to move back and forth. Shaft 221, a driving motor 222 fixed on one end of the fixed shaft 221, and a slider 223 sliding on the fixed shaft 221, the slider 223 is fixed with the scraper 21, and a screw is coaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com