Drilling mold suitable for windshield wiper

A technology for drilling molds and wipers, which is applied in the direction of drilling molds for workpieces, etc., which can solve problems such as wasting manpower, difficulty in realizing automation, and reducing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

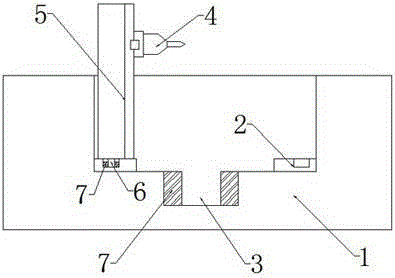

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0017] Drilling mold suitable for wipers, including: lower mold base 1, ring-shaped groove 2 placed on lower mold base 1, wiper fixing groove 3 placed at the center point of ring-shaped groove 2, movable clamped on the ring The vertical moving part in the groove 2 is connected to the drilling machine 4 of the vertical moving part. As a kind of preference, the vertical moving part is a vertical guide rail 5. The vertical guide rail 5 realizes the 360-degree circumferential rotation of the drilling machine 4 around the wiper by changing the fixed position on the ring-shaped groove 2, and the vertical guide rail 5 moves up and down to drive the drilling machine 4 to move longitudinally; Work together to realize all-round drilling.

[0018] The guide rail is provided with a clamping assembly clamped in the ring-shaped groove 2; the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com