In-shaft spline and outer circle coaxiality machining and positioning device and process method

A positioning device and internal spline technology, applied in the field of mechanical processing, can solve the problems of reducing processing accuracy, affecting tool rigidity, cumbersome operation, etc., and achieve the effect of improving coaxiality processing accuracy, improving processing accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

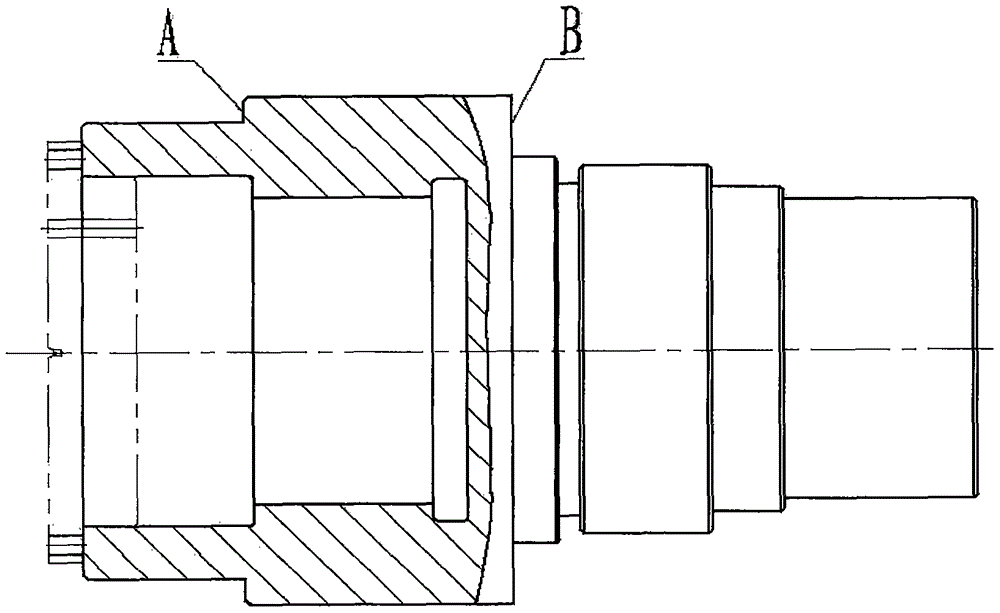

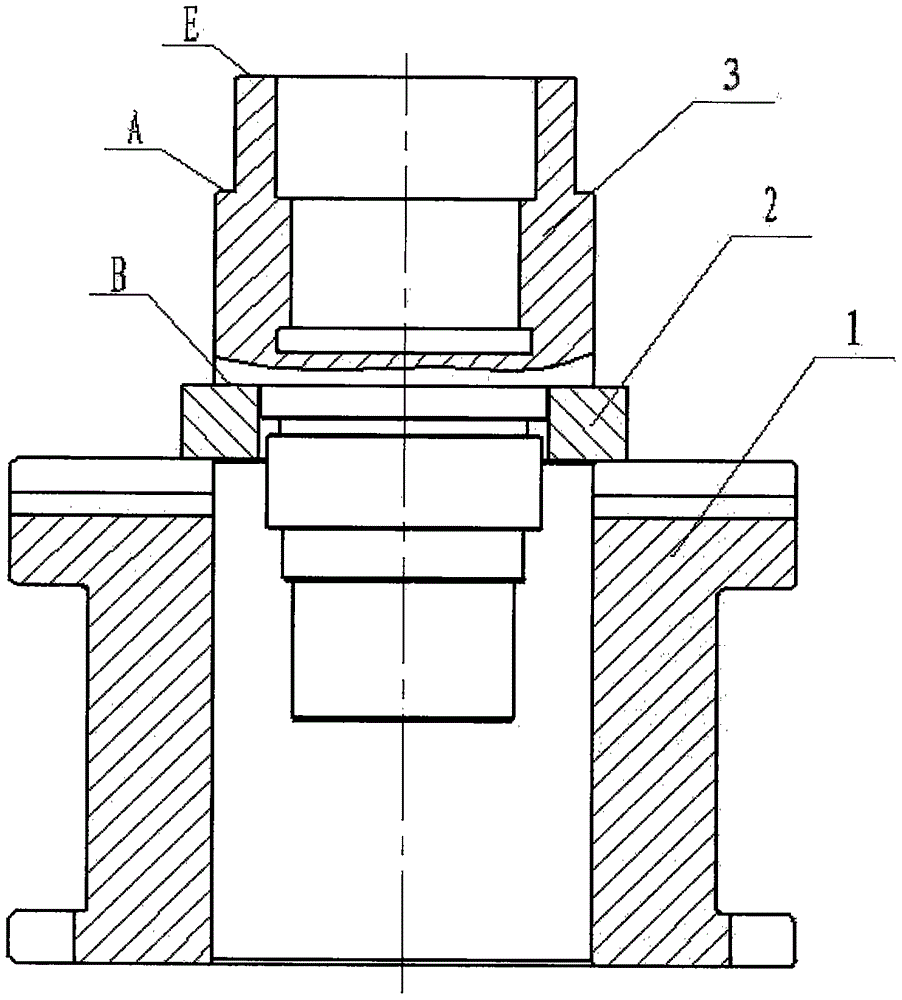

[0020] Depend on Figure 1~2 It can be seen that

[0021] Design and manufacture a positioning device with stable positioning and convenient operation. The device solves the problems of unstable positioning, non-uniform benchmarks and insufficient rigidity of the machine tool spindle when machining internal splines, improves machining accuracy, and makes clamping and alignment more reasonable. The device consists of a carcass and a gasket.

[0022] Change the process of grinding the spline hole to process after grinding the outer circle, and when grinding the outer circle, the relevant end face must be ground, so that when grinding the spline hole, the ground outer circle and the ground end face can be aligned to ensure the spline The hole has the same center as the outer circle. The processing steps to ensure the coaxiality of the inner spline and the outer circle are as follows:

[0023] Follow the steps below to complete the machining of the coaxiality of the spline in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com