Three-freedom-degree smooth driver with hybrid power source

A hybrid power, degree of freedom technology, applied in the direction of manufacturing tools, manipulators, program-controlled manipulators, etc., to achieve the effect of increasing stiffness, improving control accuracy, and good self-recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

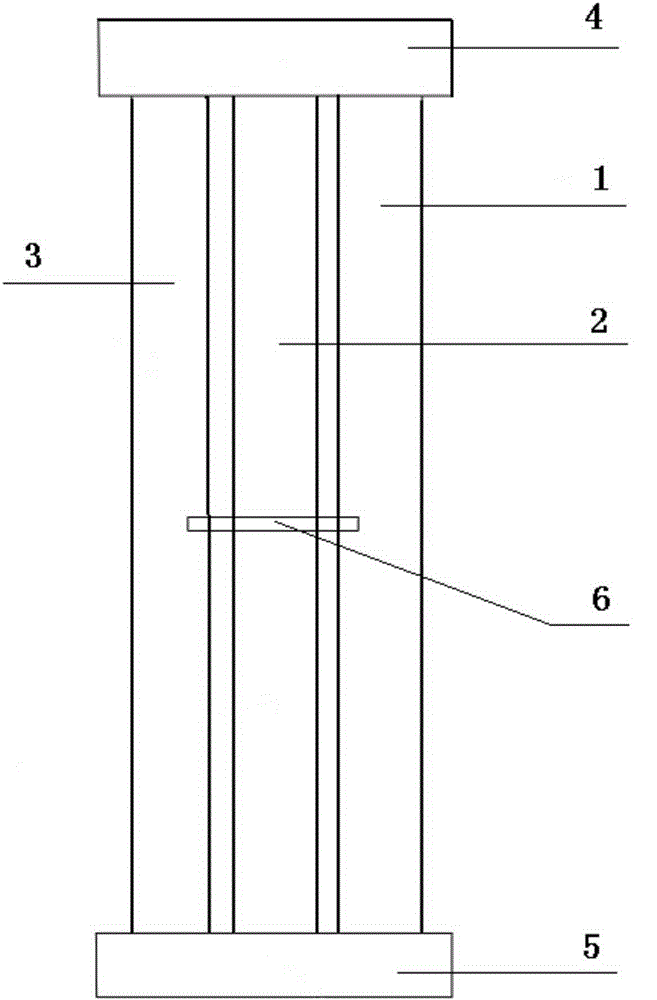

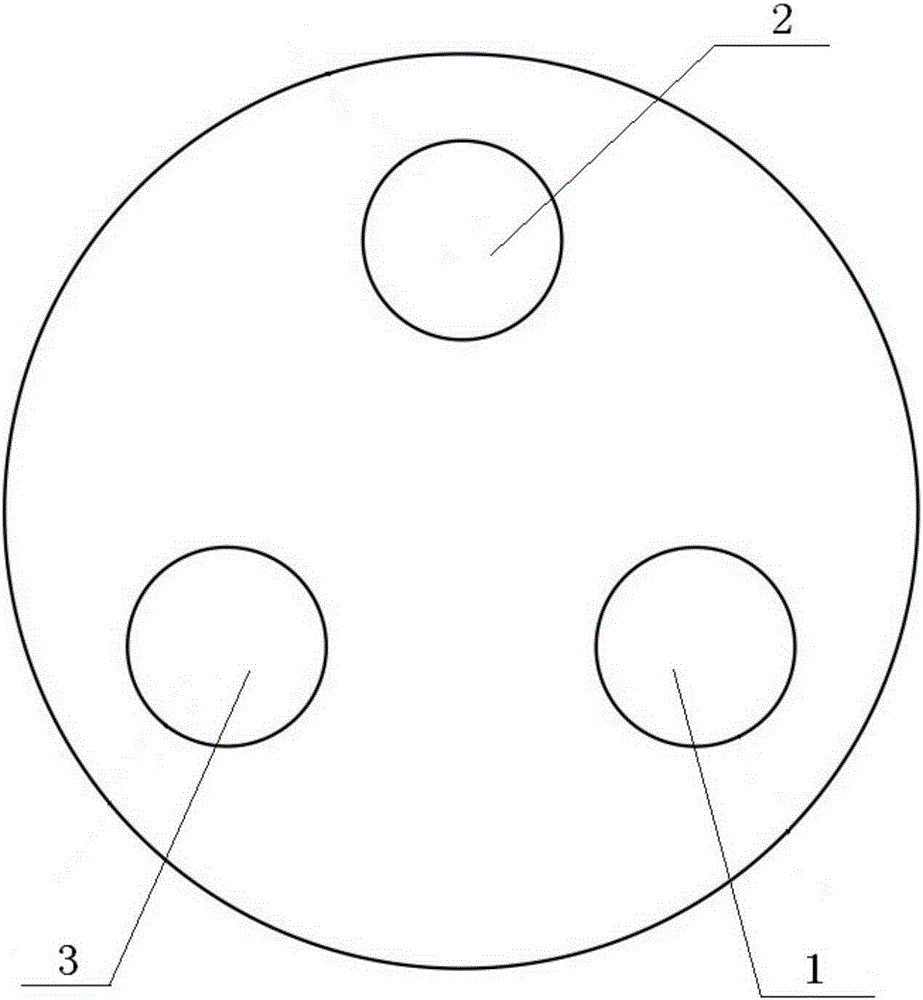

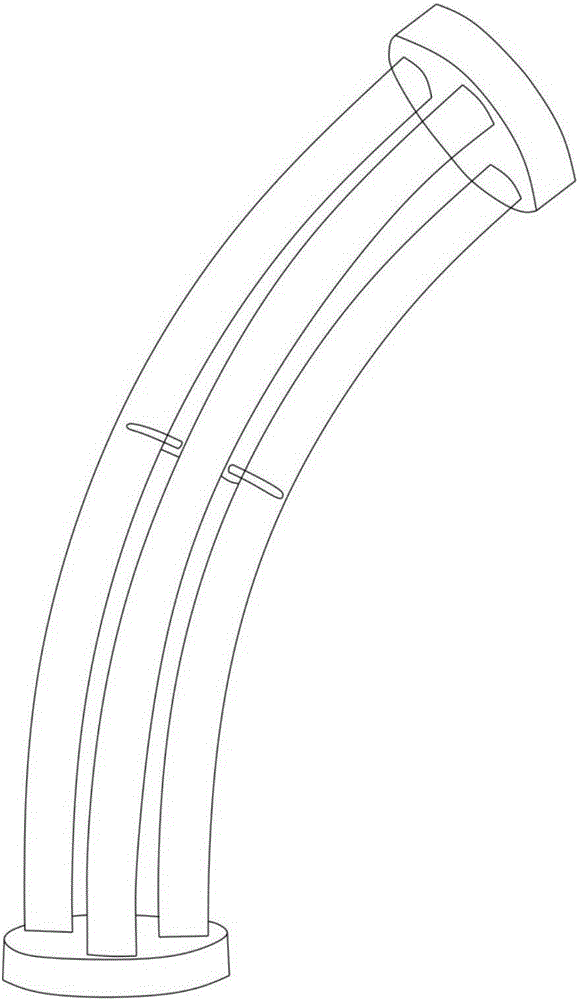

[0019] Such as figure 1 , figure 2 and image 3 As shown, a three-degree-of-freedom compliant actuator with a hybrid power source is composed of three artificial pneumatic muscles 1, 2, 3, end caps 4, 5 and a central fixed disk 6 arranged in parallel. The end cap 4 and the end cap 5 are respectively It is arranged at both ends of the three artificial pneumatic muscles 1, 2, 3, and the central fixing disc 6 is arranged in the middle of the three artificial pneumatic muscles 1, 2, 3 to fix the three artificial pneumatic muscles 1, 2, 3. By inflating any single or two artificial pneumatic muscles, the length of the three artificial pneumatic muscles will be different, so the driver of the present invention will bend in the direction of the shorter muscle; if the three artificial pneumatic muscles are filled with the same air pressure, then The overall axial expansion and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com