Washing type mold press

A molding machine and punch technology, which is applied in the field of molding machines, can solve the problems of laborious cleaning, etc., and achieve the effect of saving costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

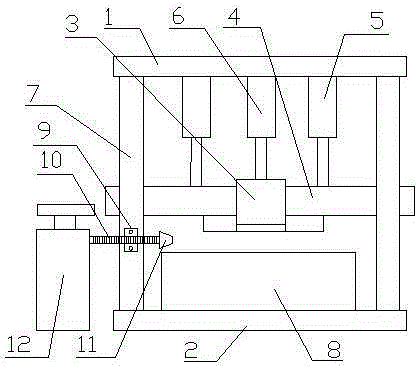

[0009] Such as figure 1 It is a structural schematic diagram of the present invention, a flushing molding press, including a top seat 1, a base 2, a punch 3, a punch seat 4, a hydraulic rod 5, a hydraulic rod 2 6, a guide post 7 and a die 8, and the top seat 1 It is fixedly connected with the base 2 through the guide post 7, the upper end of the base 2 is provided with a die 8, the top base 1 is fixedly connected with the punch base 4 through the hydraulic rod one 5, and the top base 1 is fixed with the punch 3 through the hydraulic rod two 6 Connection, the punch 3 is placed on the upper end of the die 8, the punch 3 is installed in the punch seat 4, the guide post 7 is fixedly connected with the serpentine bend 10 through the fixing ring 9, and the top of the serpentine bend 10 is provided with a nozzle 11 , the tail end links to each other with water pump 12.

[0010] First turn on the motor 11, so that the motor 11 drives the fan 10 to rotate, so that the dirt on the die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com