Car bumper device with multiple buffering

A technology for automobile bumpers and buffer devices, applied in bumpers, vehicle parts, transportation and packaging, etc., can solve the problems of increasing manufacturing and installation difficulty, reducing strength, and high cost, so as to improve personal safety, avoid direct collision, principle reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further.

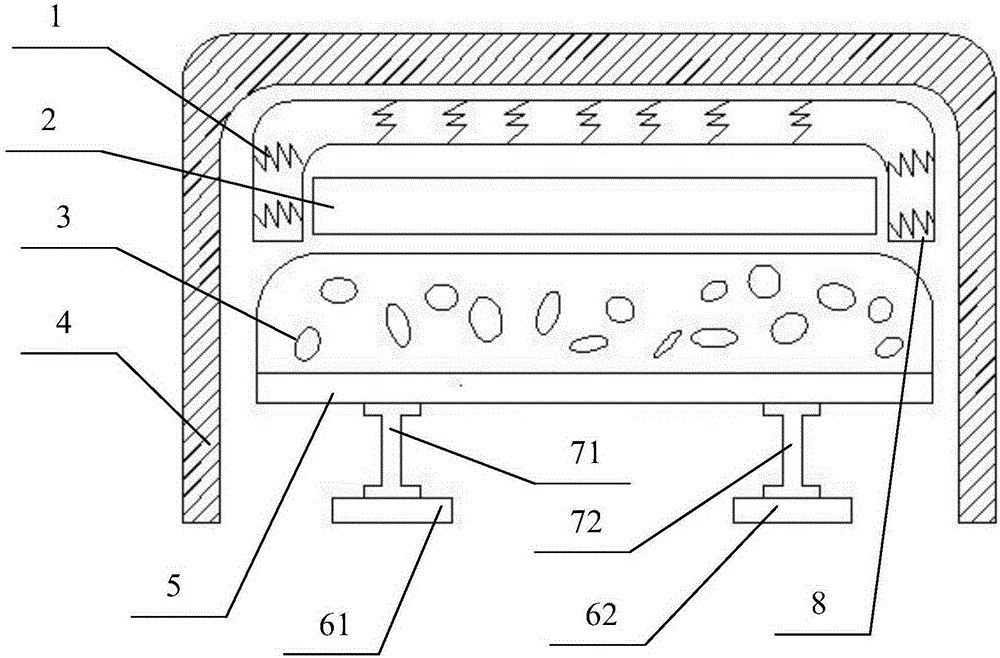

[0010] Referring to the accompanying drawings, a multi-buffer automobile bumper device includes a buffer spring 1, an anti-collision steel frame 2, an air cavity 3, an outer cover plate 4, a supporting plate 5, a bracket one 61, a bracket two 62, a mounting plate one 71, Mounting plate two 72, connecting frame 8. Wherein, buffer spring 1 is inside connecting frame 8, and connecting frame 8 is plastic material, and it has the effect of absorbing energy, is made of the framework that protects buffer spring 1 by it, reaches the effect of double-layer buffering. The anti-collision steel frame 2 is made of aluminum alloy, and the anti-collision steel frame 2 and the connecting frame 8 are connected by screws (not shown in the figure), which not only has high strength but also meets the requirements of light weight. The filling gas inside the air cavity 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com