A washing machine panel glass transfer car

A technology for panel glass and transfer car, which is applied to motor vehicles, trolleys, multi-axle trolleys, etc., can solve the problems of inconvenient use, easily damaged glass, and the difference between the center of gravity of flat glass and curved glass, etc., so as to reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

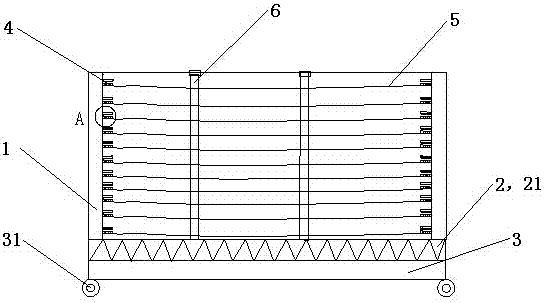

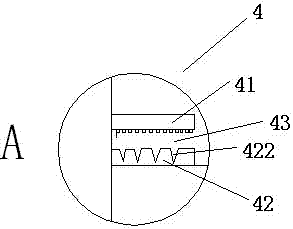

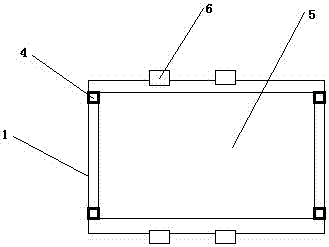

[0019] Such as Figure 1-3 As shown, a washing machine panel glass transfer vehicle includes a fixed frame 1, an anti-vibration base 2 and a fixed bottom plate 3 from top to bottom, and several groups of glass fixing parts 4 are arranged on the opposite sides of the fixing frame 1, and each group of glass is fixed The part 4 includes a total of four glass fixing parts 4 fixed on two opposite side walls of the fixed frame 1, two for each side wall, and an airbag cushion layer 5 is connected between each group of glass fixing parts 4. As preferably, the transfer vehicle of the present invention is also provided with an inflator (not shown), used to inflate the airbag cushion layer, and the airbag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com