A kind of glossy putty special for metallic paint and using method thereof

A smooth putty and metallic paint technology, applied in the direction of filling slurry, etc., can solve the problems of insufficient adhesion between the putty layer and the surface layer, poor sanding and flexibility, and insufficient smooth and delicate surface, etc., to achieve perfect decorative effect , easy to polish, long-lasting decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

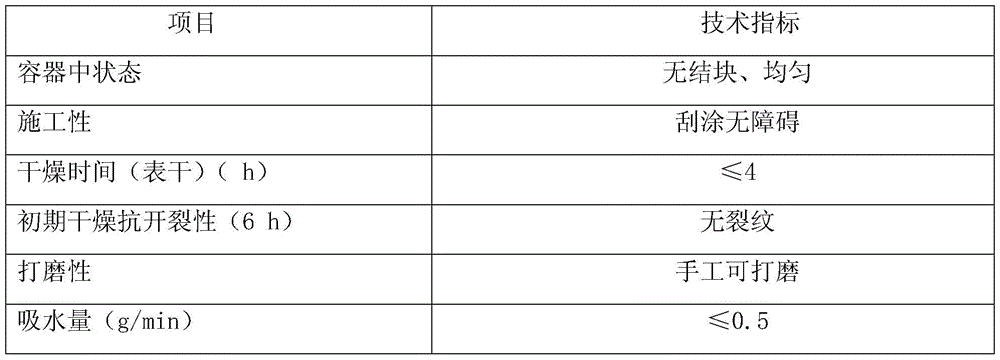

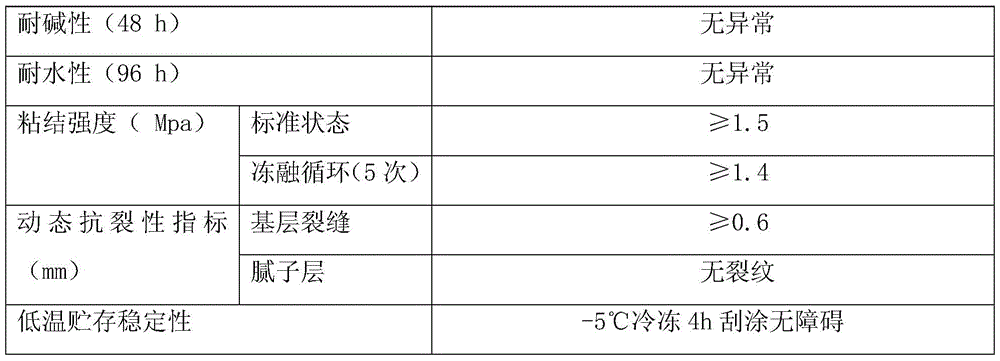

Image

Examples

Embodiment 1

[0026] A special glossy putty for metallic paints, comprising the following raw materials mixed evenly in parts by weight: 15 parts of hydroxypropyl methylcellulose, 6.5 parts of inorganic clay glue, 3 parts of polyvinyl alcohol, 30 parts of acrylic emulsion, wood fiber 0.3 parts, 0.1 parts of BASF WBA, 0.1 parts of Chisso coalescent, 0.1 parts of Rohm and Haas preservative, 0.2 parts of Sloco-oily wetting and dispersing agent, 35 parts of superfine heavy calcium, superfine quartz powder 20 servings.

Embodiment 2

[0028] A special glossy putty for metallic paints, comprising the following parts by weight of raw materials uniformly mixed, 10 parts of hydroxypropyl methylcellulose, 4 parts of inorganic clay glue, 2 parts of polyvinyl alcohol, 25 parts of acrylic emulsion, wood fiber 2 parts, 0.2 parts of Chisso film-forming aid, 20 parts of superfine heavy calcium, and 10 parts of superfine quartz powder.

Embodiment 3

[0030] A special glossy putty for metallic paints, comprising the following raw materials mixed evenly in parts by weight: 25 parts of hydroxypropyl methylcellulose, 10 parts of inorganic clay glue, 5 parts of polyvinyl alcohol, 40 parts of acrylic emulsion, wood fiber 5 parts, 1 part of BASF WBA, 1 part of Chisso coalescent, 1 part of Rohm and Haas preservative, 2 parts of Sloco-oily wetting and dispersing agent, 250 parts of superfine heavy calcium, 30 parts of superfine quartz powder share.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com