Polycaprolactone multi-layer composite degradable packaging film

A technology of polycaprolactone and multi-layer compounding, applied in the direction of sustainable packaging, packaging, wrapping paper, etc., can solve the problems of high thermal shrinkage rate and poor heat resistance of the film, achieve good softness and mechanical properties, increase The effect of high flexibility and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

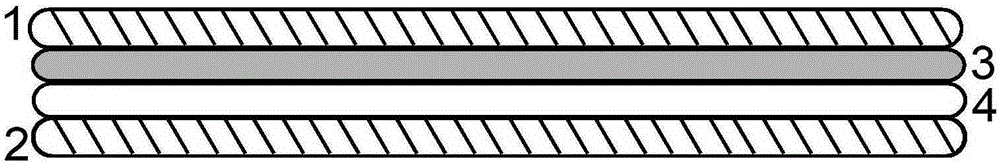

[0028] The polycaprolactone multilayer composite degradable packaging film described in this embodiment, such as figure 2 As shown, it consists of four resin layers, and its structure includes a first outer layer 1 and a second outer layer 2 containing biodegradable components, and an inner layer including biodegradable components covering one of the outer layers a3 and inner layer b4. Said inner layer is any layer in a multilayer structure having both major surfaces directly adhered to another layer of the structure and said outer layer is a multilayer structure having one and only one surface adhered to any layer above another layer in the structure.

[0029] Any resin layer of the packaging film is a single polycaprolactone material or a blend of different proportions of polycaprolactone and other resin materials; and each resin layer of the packaging film is from the center to the outer layer, and its polycaprolactone The content of caprolactone changes gradually in the...

Embodiment 2

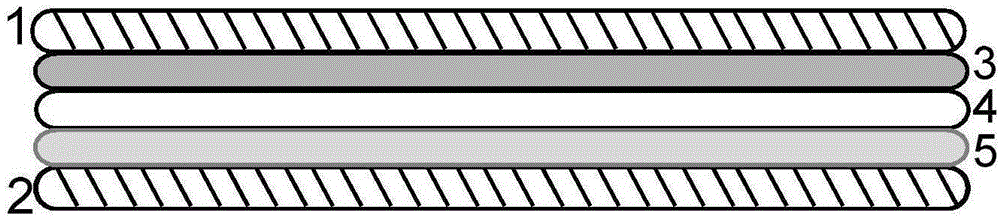

[0033] The polycaprolactone multi-layer composite degradable packaging film prepared in this embodiment, such as image 3 As shown, it consists of five resin layers, and its structure includes a first outer layer 1 and a second outer layer 2 containing biodegradable components, and three outer layers including biodegradable components covering one of the outer layers Inner layers, namely inner layer a3, inner layer b4 and inner layer c5.

[0034] Any resin layer of the packaging film is a single polycaprolactone material or a blend of different proportions of polycaprolactone and other resin materials; and each resin layer of the packaging film is from the center to the outer layer, and its polycaprolactone The content of caprolactone changes gradually in the form of gradient, and its melting temperature also changes gradually in the form of gradient.

[0035]Put the first outer layer 1 masterbatch component namely the polycaprolactone that contains 80% by weight, the polyval...

Embodiment 3

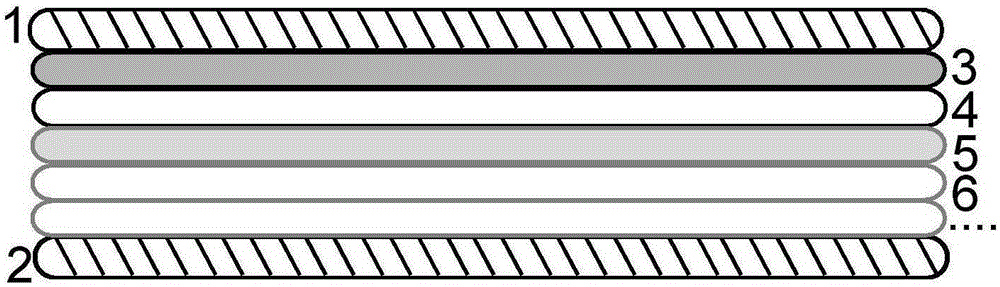

[0038] The polycaprolactone multi-layer composite degradable packaging film prepared in this embodiment, such as Figure 4 As shown, it consists of six resin layers, and its structure includes a first outer layer 1 and a second outer layer 2 containing biodegradable components, and four outer layers including biodegradable components covering one of the outer layers Inner layers, namely inner layer a3, inner layer b4, inner layer c5 and inner layer d6.

[0039] Any resin layer of the packaging film is a single polycaprolactone material or a blend of different proportions of polycaprolactone and other resin materials; and each resin layer of the packaging film is from the center to the outer layer, and its polycaprolactone The content of caprolactone changes gradually in the form of gradient, and its melting temperature also changes gradually in the form of gradient.

[0040] Put the first outer layer 1 masterbatch component namely the polycaprolactone that contains 95% by wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com