A method and structure for solving rigid-flexible overlap before road overlaying

A rigid-flexible, old-pavement technology, applied in the direction of roads, roads, pavement details, etc., can solve problems such as influence, bad society, and influence on the performance of overlays, and achieve the effect of mature technology, improved service life, and reduced impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

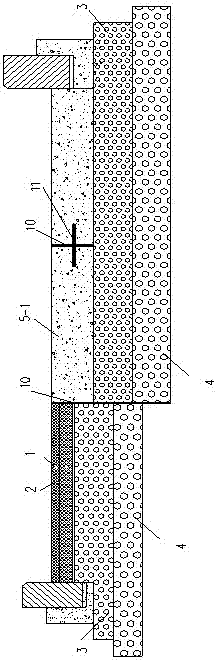

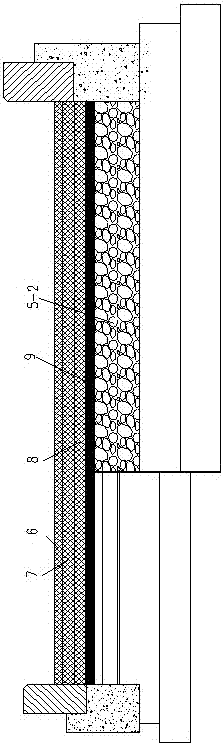

[0018] Such as figure 1 As shown, the standard cross-sectional diagram of the road surface structure before the renovation, the road surface of the non-motor vehicle lane in the old pavement structure is the upper layer 1 (made of 4cmAC-16 medium-grained asphalt concrete) and the lower layer 2 (made of 7cmATB -25 densely graded asphalt stabilized gravel) and cement stabilized gravel base 3 and 15cm mountain stone cushion 4;

[0019] The road surface of the motorway in the old pavement structure consists of cement layer 5-1 (composed of 22cmC35 cement concrete), 20cm thick cement stabilized gravel base 3 and 15cm mountain stone cushion 4 from top to bottom; in addition, It also includes the longitudinal joint at the junction of the old asphalt pavement and the old cement pavement, the longitudinal joint 10 of the cement pavement itself, and the tie rod 11 between the longitudinal joints of the cement pavement.

[0020] Above-mentioned 1,2,3,4,5-1,10,11 all belong to old struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com