Super-long prestressed reinforcement traction locker

A technology of prestressed steel bars and traction locks, applied in the directions of columns, piers, pillars, etc., can solve the problems that the welded joints are easily stuck inside the corrugated pipe and the local structure of the main body is damaged, and achieves the effect of facilitating traction and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The ultra-long prestressed steel bar traction locking device provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

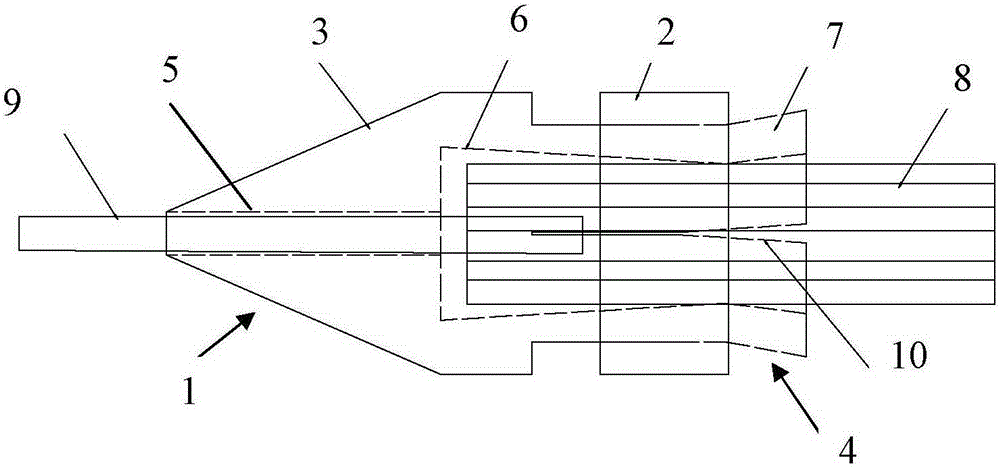

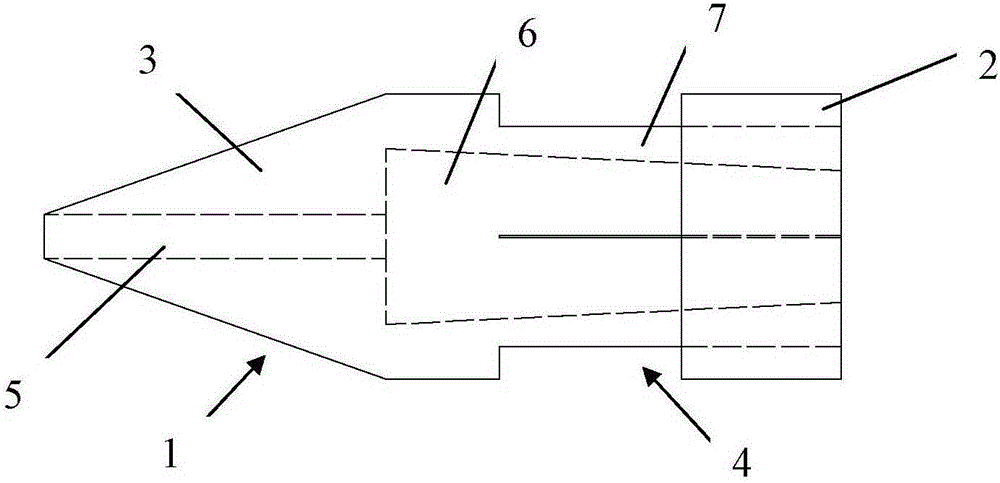

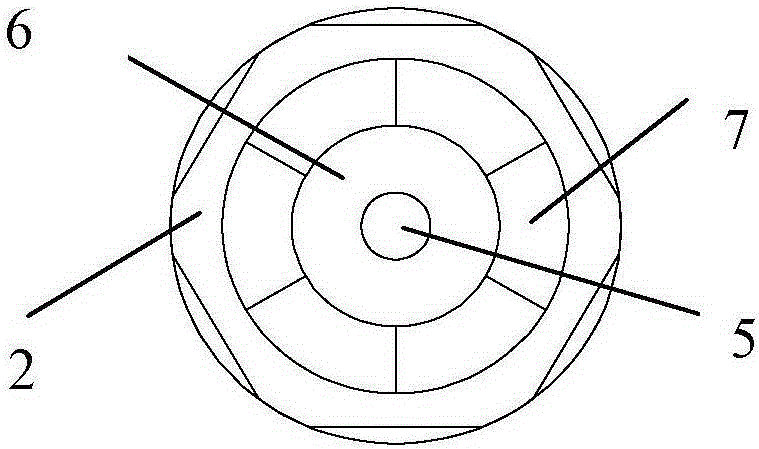

[0015] Such as figure 1 — Figure 5 As shown, the ultra-long prestressed steel bar traction locking device provided by the present invention includes a restraint device 1 and a nut 2; wherein the restraint device 1 is integrally formed by a cone part 3 and a tail part 4, the cone part 3 is a frustum-shaped structure, and the front part A steel bar through hole 5 is formed at the axial center of the cone tip, and a steel bar setting hole 6 that communicates with the above steel bar through hole 5 and has a diameter greater than the steel bar through hole 5 is formed at the rear axial center; One end is connected to the edge of the tendon setting hole 6 on the rear end surface of the cone part 3 and is formed by a circular arc-shaped piece 7 with multiple gaps, and thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com