Built-in anchorage type prestress FRP rib tensioning and anchoring device

An anchoring device and prestressing technology, applied in structural elements, building components, building reinforcements, etc., can solve problems such as difficulty in use, fracture of FRP bars, low transverse shear strength and low longitudinal tensile strength, etc. Simple operation and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

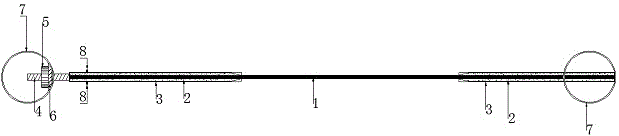

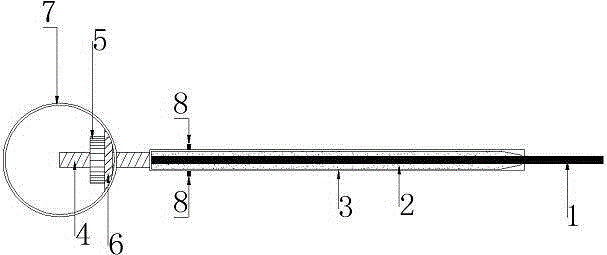

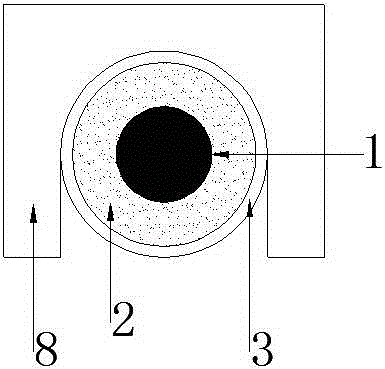

[0026] Such as figure 1 , figure 2 , Figure 4 , Figure 6 As shown, a built-in anchor type prestressed FRP tendon tension anchoring device, including prestressed FRP tendon 1, bonding material 2, steel sleeve 3, screw rod 4, nut 5, annular steel washer 6 and circular anchor Ring 7, the two ends of the prestressed FRP bars 1 are respectively inserted into the open ends of the steel sleeve 3 at the tension end and the anchor end, and fixed with bonding material 2, the steel sleeve 3 at the tension end A section of screw rod 4 is welded to the closed end of the screw rod 4, so that the screw rod 4 passes through the ring wall of the circular anchor ring 7 at the tension end, and an annular steel gasket 6 and a nut 5 matching the screw rod 4 are installed in the circular anchor ring 7; The closed end of the steel sleeve 3 at the end passes through the ring wall of the circular anchor ring 7 at the anchor end, and is welded together with the circular anchor ring 7.

[0027] S...

Embodiment 2

[0039]This embodiment is basically the same as the above-mentioned embodiment 1, the difference is that there are two prestressed FRP tendons 1 and they are relatively close to each other. At this time, the anchor rings at the tensioning end and the anchoring end can be improved, and the concrete member The hole slots on the surface are also adjusted accordingly, such as Figure 7 As shown, other specific implementation steps are the same as those in Embodiment 1, and the prestressing force can be applied to the component with two prestressing FRP tendons at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com