Secondary cell top cover and secondary cell

A secondary battery and top cover technology, which is applied in the direction of battery cover/end cover, battery pack parts, battery box/outer, etc., which can solve the hidden dangers of increasing battery safety, the flipping pieces cannot be flipped at the same time, and the current of the cell circuit is large and other issues to achieve the effect of reducing the risk of being cut off or blown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. The terms "front", "rear", "left", "right", "upper" and "lower" mentioned in the text refer to the placement state of the top cover of the secondary battery in the drawings.

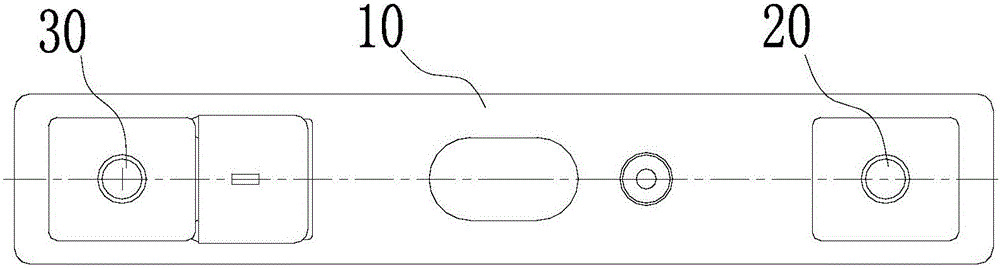

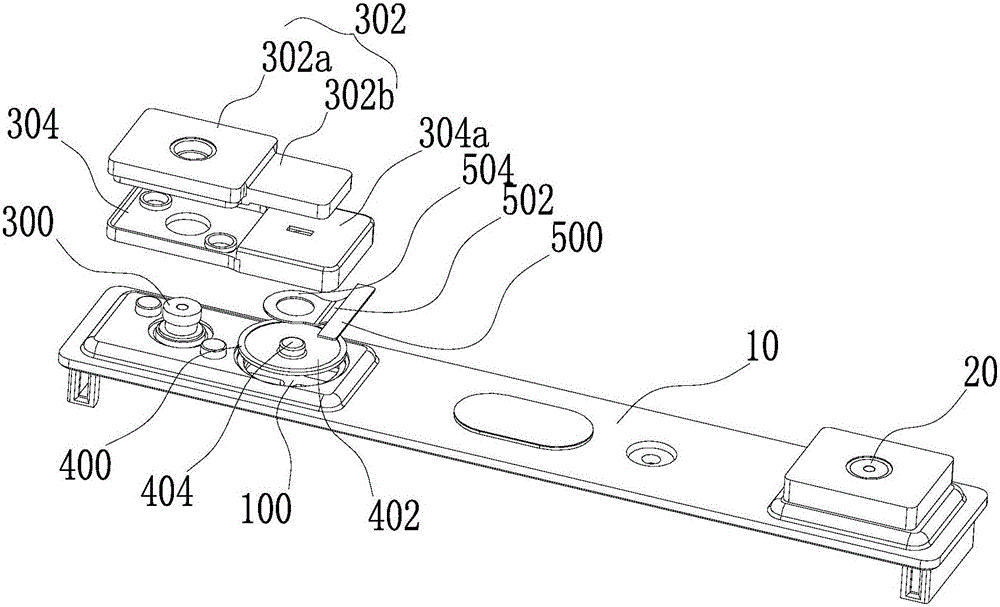

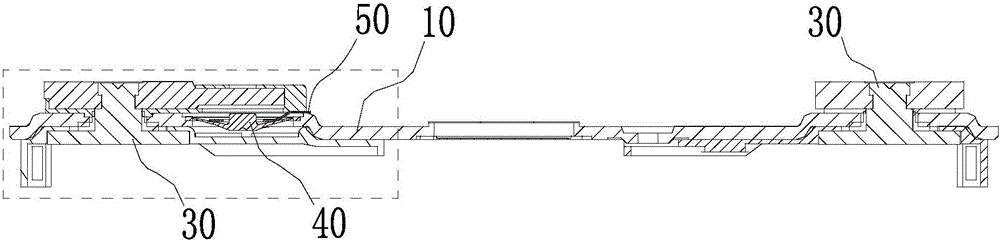

[0063] An embodiment of the present application provides a secondary battery, which includes structures such as a top cover of the secondary battery, a bare battery cell, and a battery cell case. Among them, such as Figures 1 to 3As shown, the top cover of the secondary battery includes a top cover sheet 10 , a first pole unit 20 , a second pole unit 30 , a flipping piece 40 and a conductive piece 50 . The top cover sheet 10 is hermetically assembled on the upper part of the cell casing (not shown in the figure), and the first pole unit 20 and the second pole unit 30 are respectively electrically connected to the bare cell (not shown in the figure), fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com