A car glass rail

An automotive glass and guide rail technology, applied in vehicle parts, engine sealing, sealing devices, etc., can solve the problems of loose upper and lower guide rails, difficult installation, abnormal vibration of the whole vehicle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

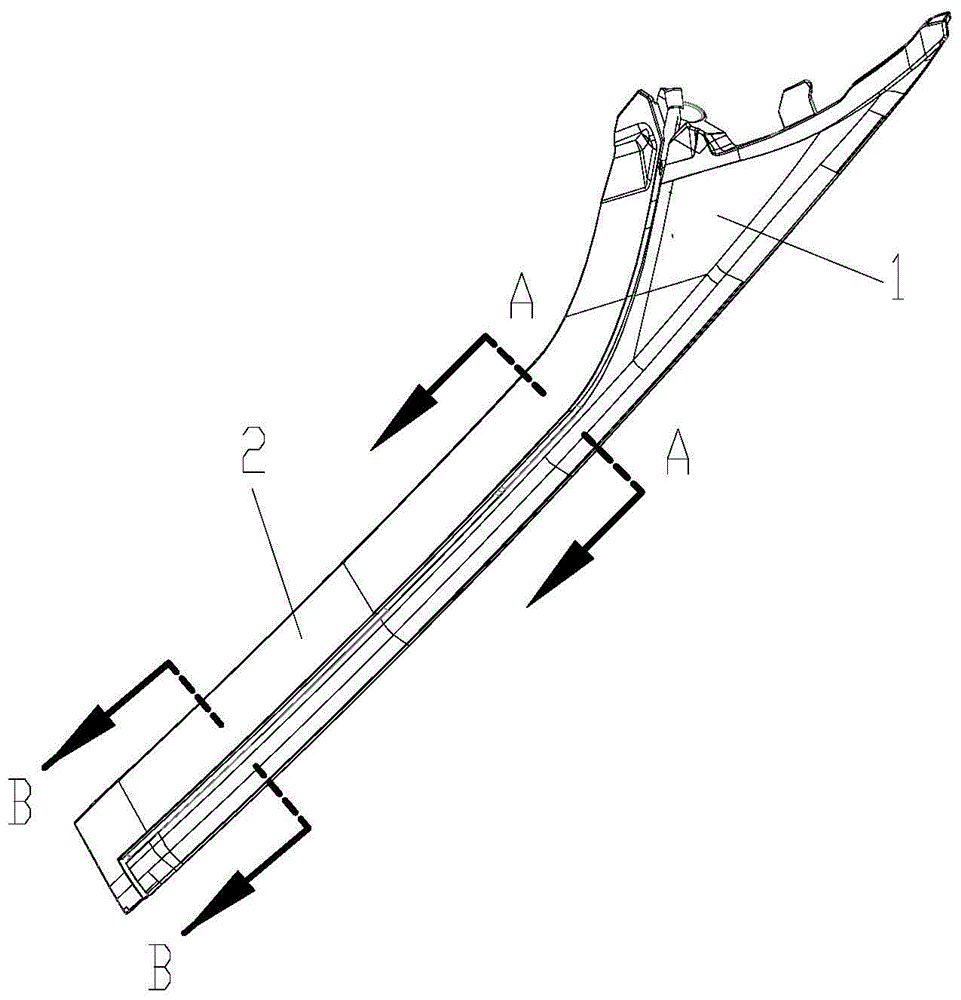

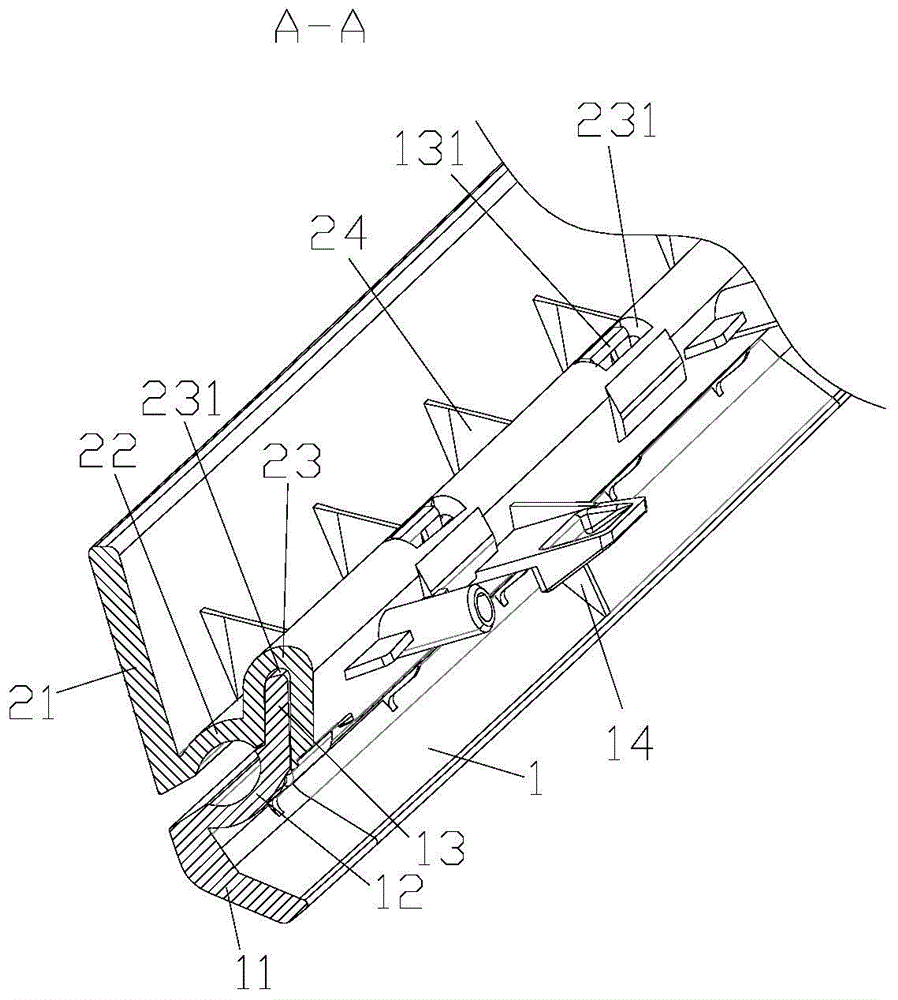

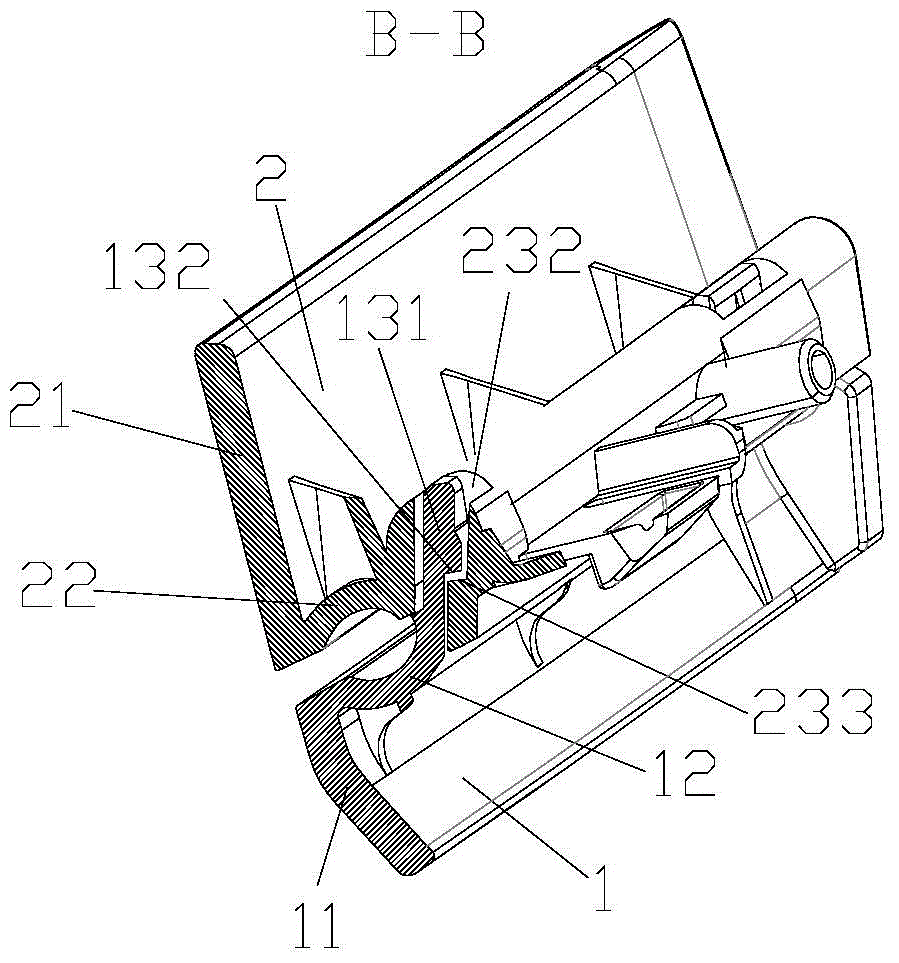

[0021] like Figures 1 to 3 As shown, a kind of automobile glass guide rail comprises an upper guide rail 1 and a lower guide rail 2, a U-shaped column 23 is arranged on the length direction of the lower guide rail 2, and a U-shaped groove 231 is formed on the described U-shaped column 23. The upper guide rail 1 is provided with a board 13 that is compatible with each U-shaped groove 231; along the length direction of the board 13, a plurality of plug-in blocks 131 are provided, and each U-shaped groove 231 is provided with a The jack 232 that is matched with each plug 131; when installing the upper and lower rails, insert the plug 13 on the upper rail 1 into the U-shaped groove 231 on the lower rail 2, and insert the plug 131 on the upper rail 1 into the lower rail 1 at the same time. In the socke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com