Support for blade testing and blade testing device comprising support

A testing device and fan blade technology, applied in pump control, non-variable-capacity pump, machine/engine, etc., can solve the problem of unreliable fan blade efficiency parameters, large deviation of fan blade efficiency parameters, and difficulty in optimizing the motor and fan blades. Matching and other issues to achieve the effect of improving design capabilities and development efficiency, reducing structural wind resistance, and increasing test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

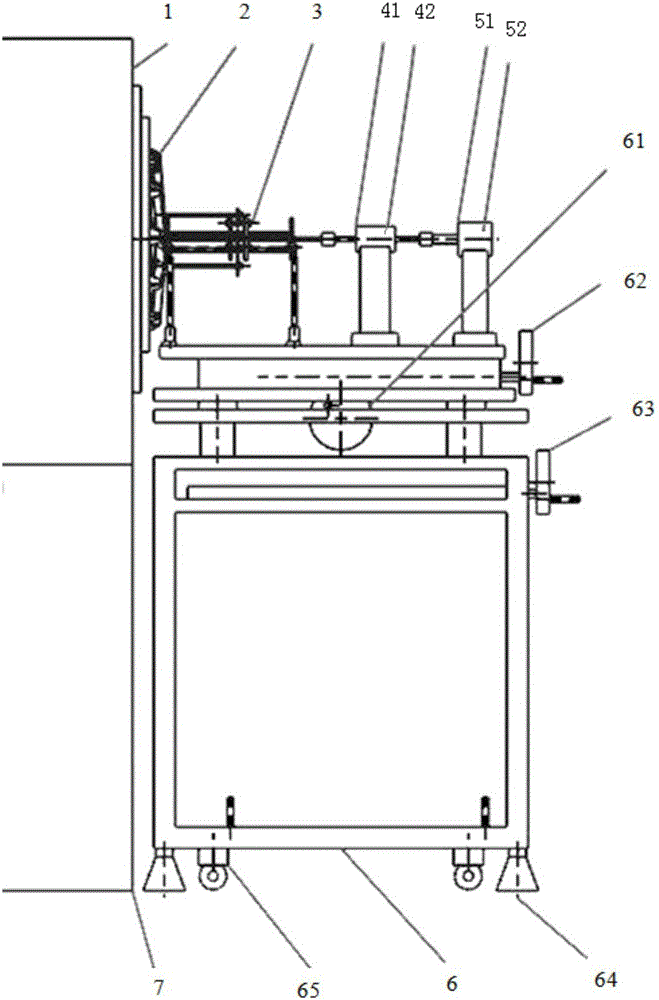

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

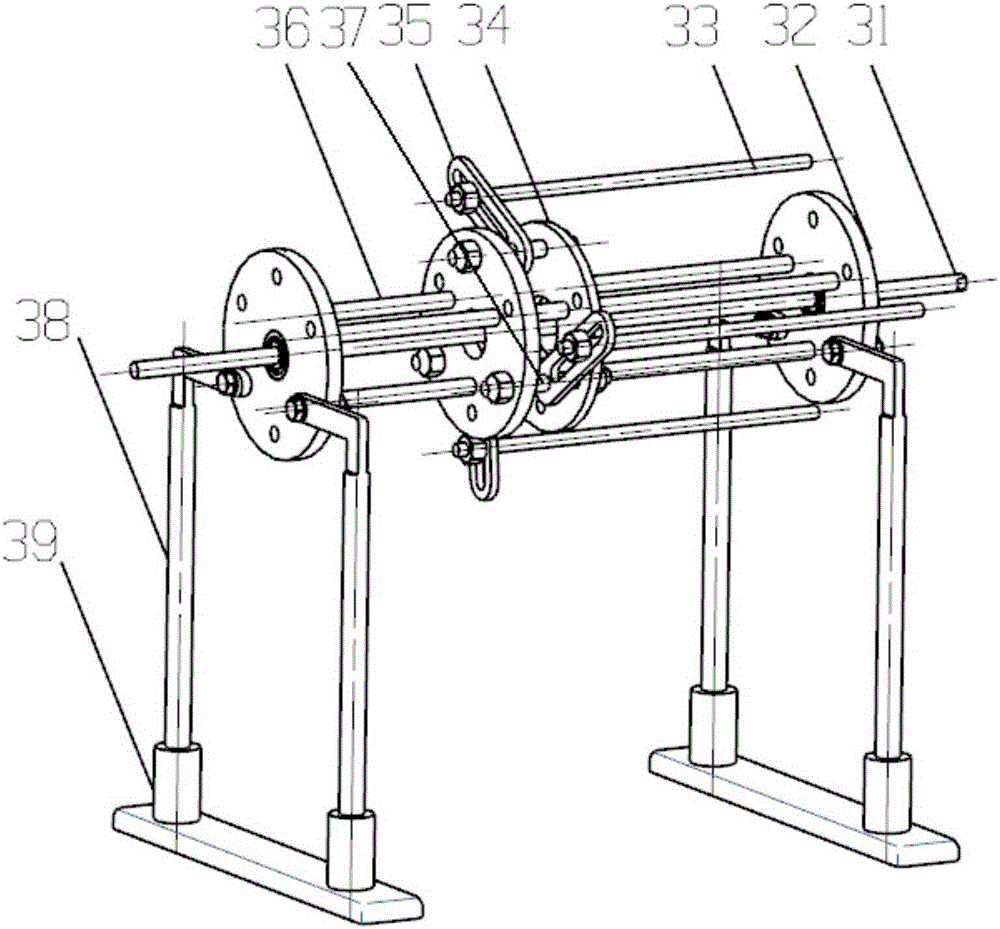

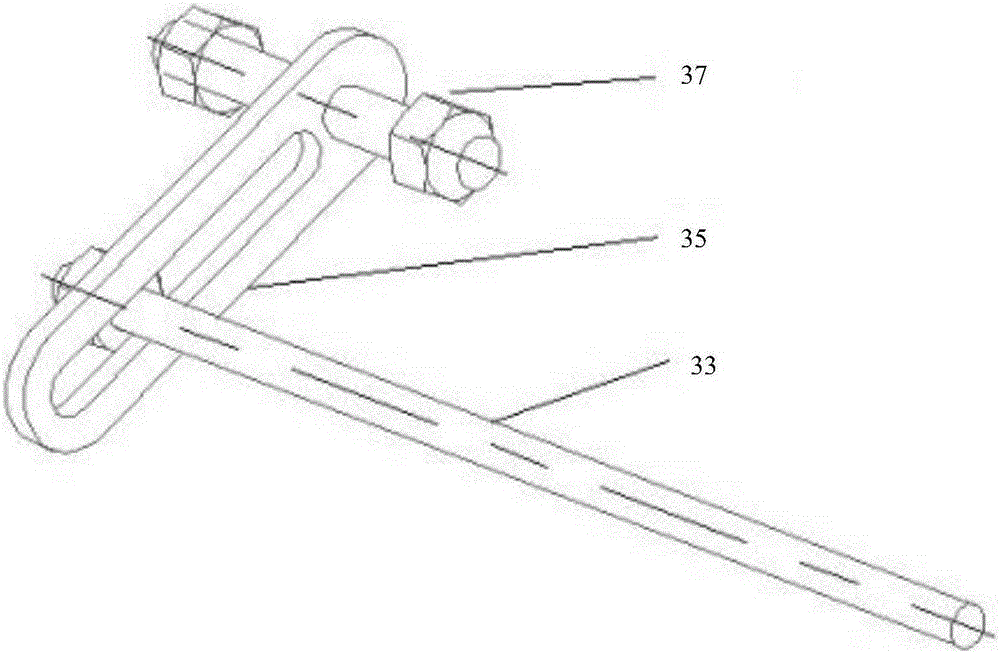

[0032] according to figure 1 , figure 2 The shown bracket for wind blade testing includes a central shaft 31, and the two ends of the central shaft 31 are supported by two end caps 32, and each end cap 32 is fixed with a screw rod 38, so that the end caps 32 do not produce relative Movement, screw rod 38 bottoms are fixed with threaded column 39, and screw rod 38 and threaded column 39 constitute the base of support, and the cooperation of threaded column 39 and screw rod 38 can adjust the height of support. There are bearings in the end cover 32, so that the central shaft 31 can rotate in the end cover 32. The central shaft 31 is covered with two fastening discs 34, and the fastening discs 34 are between the end caps 32. The shaft 31 is in contact, and the fastening disc 34 is penetrated with a fixed rod 36, and the fixed rod 36 is fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com