Error-proof adjusting assembly of AMT clutch

A technology for adjusting components and clutches, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of AMT not running normally, clutches are easily damaged, etc., and achieve simple structure, reliable operation, and reduce errors. The effect of pretending probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

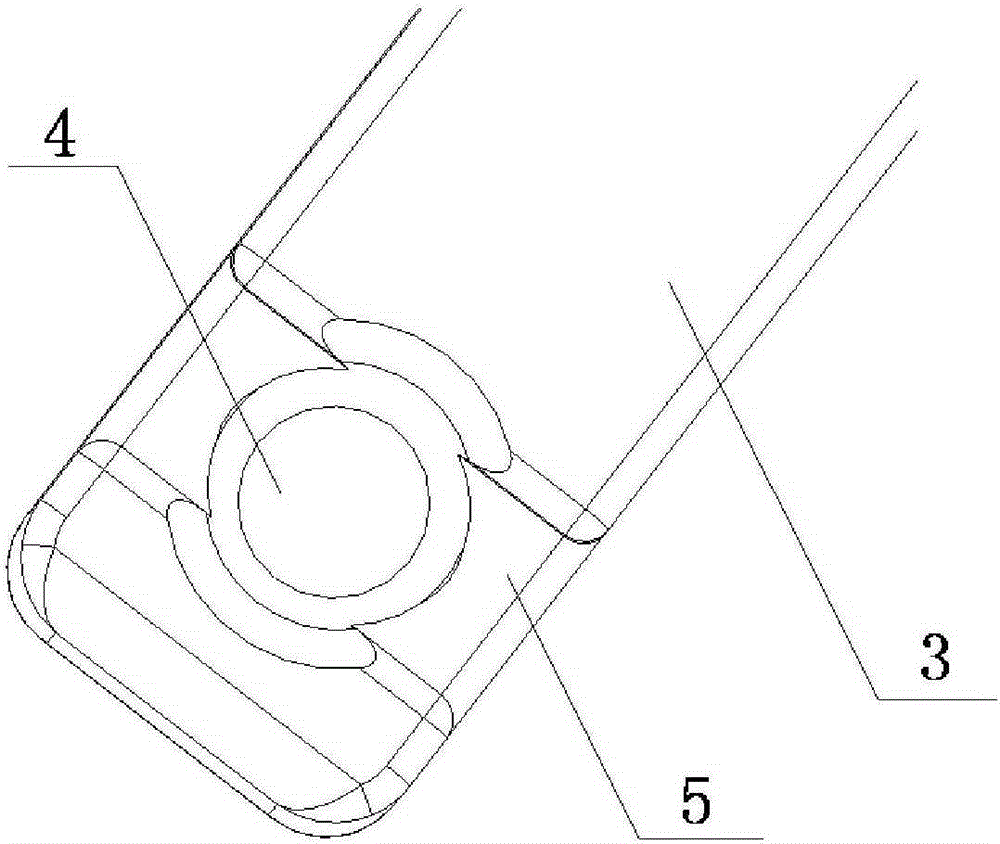

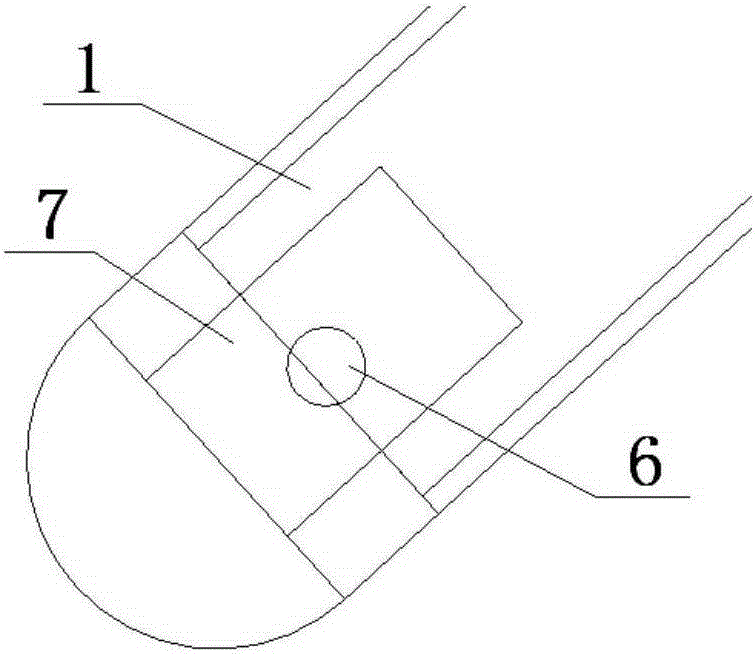

[0022] see Figure 1-5 The traditional clutch adjustable push rod structure includes a clutch push rod 11, a hex nut 12 and a clutch adjustment rod 13. Compared with the traditional clutch adjustable push rod structure, the present invention structurally includes a separation fork 3 and a separation push rod 1; separation A ball socket 4 for connecting the end of the separation push rod 1 is opened on the shift fork 3, and the surface of the separation shift fork 3 at the mouth of the ball socket 4 is processed with an arc-shaped groove 5; the separation push rod 1 is inserted into the bottom of the ball socket 4 for opening In the through hole 6 where the anti-error pin 2 is installed, the bottom of the separation push rod 1 is provided with a plane groove 7 at the position where the through hole 6 is processed, which is convenient for punching. The anti-er...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com