Linear electromagnetic valve

A solenoid valve and glyph technology, applied in the field of solenoid valves, can solve the problems of not being suitable for use in places with dense pipelines, occupying a small space, tubular battery valves, and high height of solenoid valve cores, and achieving simple and compact structure, simple installation, and easy installation. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

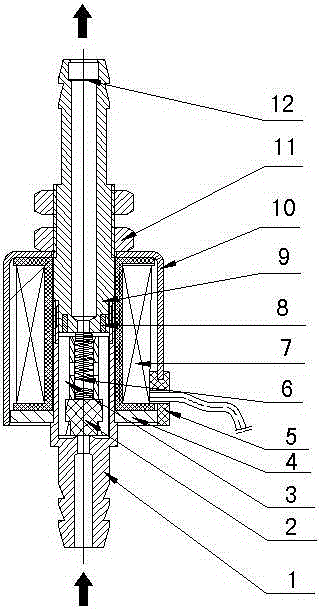

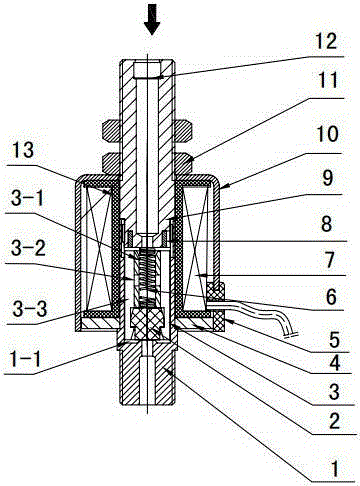

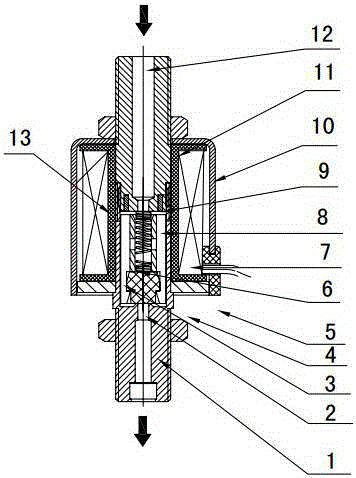

[0039] The trachea fixing part of Embodiment 1 adopts an external thread joint, the trachea fixing part of Embodiment 2 adopts an internal thread joint, and the trachea fixing part of Embodiment 2 adopts an intubation joint.

[0040] as shown in the picture As shown, Embodiment 4 to Embodiment 6 also adopted the above three matching methods respectively. The difference from the previous three embodiments is that it adopts the working mode of the reverse air circuit, the air intake is located in the air hole in the valve body, and the air outlet is the air hole in the static iron core.

[0041] Since the intake air directly acts on the bottom of the packing block, there is a tendency to push the packing block upwards. In order to achieve the sealing effect, the spring force of this type of solenoid valve is greater than that of the air intake on the static iron core.

[0042] The present invention maintains the air inlet, air outlet and other air passages on a straight line w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap