Control method and device for preventing high temperature, and air conditioner

An air conditioner and anti-high temperature technology, applied in heating and ventilation control systems, heating methods, lighting and heating equipment, etc., can solve problems such as high exhaust pressure and compressor overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

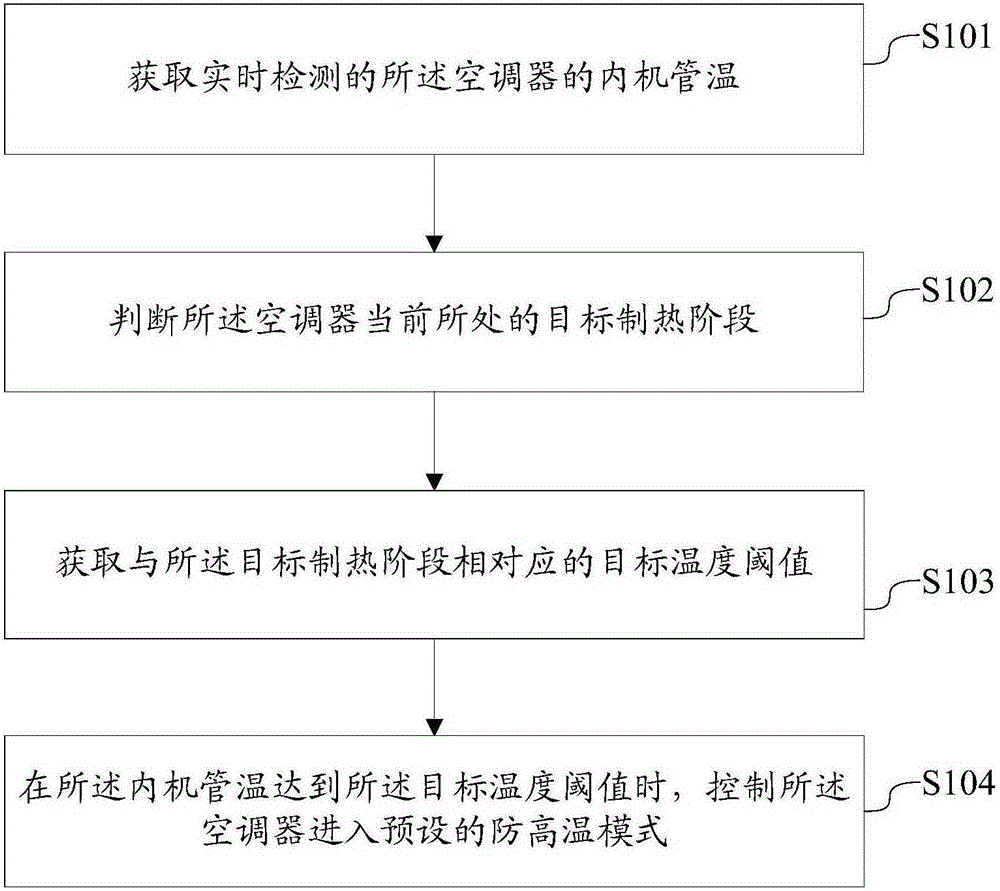

[0056] This embodiment one discloses a high temperature prevention control method, the method is applied to an air conditioner, refer to figure 1 , the method may include the following steps:

[0057] S101: Obtain the real-time detected internal tube temperature of the air conditioner.

[0058] Among them, the real-time internal unit tube temperature data of the air conditioner during the whole heating process can be collected through the temperature sensing package.

[0059] S102: Determine the current target heating stage of the air conditioner.

[0060] Corresponding to the difference between the actual tube temperature of the internal unit and the temperature detected by the temperature sensing package, the whole heating process of the air conditioner includes two stages: the heating start-up stage and the heating stable operation stage.

[0061] In this embodiment, it is determined that the air conditioner is in the heating start-up stage specifically through the follow...

Embodiment 2

[0088] In this example, refer to Figure 4 , the high temperature control method may also include the following steps:

[0089] S105: If the target heating stage is the heating start-up stage, and the air conditioner is currently in the high temperature prevention mode, when the pipe temperature of the indoor unit is not higher than the preset third temperature threshold, control The air conditioner exits the high temperature protection mode;

[0090] S106: If the target heating stage is a heating stable operation stage, and the air conditioner has entered the high temperature prevention mode, when the pipe temperature of the internal unit is not higher than the preset fourth temperature threshold, Controlling the air conditioner to exit the high temperature protection mode.

[0091] For the two stages included in the whole heating process, this embodiment pre-sets the temperature threshold for exiting the high temperature protection mode:

[0092] Set the temperature thres...

Embodiment 3

[0096] Embodiment 3 discloses a high temperature protection control device, which corresponds to the high temperature protection control method disclosed in the above embodiments.

[0097] Corresponding to embodiment one, refer to Figure 5 , the device includes a first acquisition module 100 , a judgment module 200 , a second acquisition module 300 and a first control module 400 .

[0098] The first acquiring module 100 is configured to acquire the real-time detected internal tube temperature of the air conditioner.

[0099] The judging module 200 is configured to judge the current target heating phase of the air conditioner.

[0100] Wherein, the judging module 200 includes a first judging unit and a second judging unit.

[0101] The first judging unit is configured to detect that the air conditioner does not meet the preset heating and starting process end conditions under the premise that the air conditioner meets the preset heating and starting process start conditions in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com