High-pressure grouting lifting deformation monitor and installation method thereof

A technology of lifting deformation and high-pressure grouting, which is applied in the direction of mechanical solid deformation measurement, etc., can solve the problems affecting the observation accuracy of the lifting deformation observation device, achieve the effect of ensuring reliability and deformation observation accuracy, and preventing grouting and consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

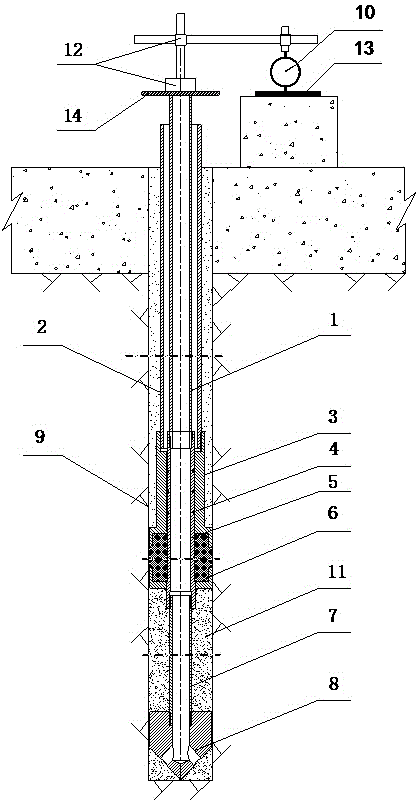

[0034] A high-pressure grouting lifting deformation monitoring device, such as figure 1 As shown, it includes a mounting hole 9, a reference pipe 1, a protection pipe 2, and a ground lift observation dial indicator 10. The installation hole 9 is a specially drilled hole for embedding the reference pipe 1 and the protection pipe 2; the lower end of the reference pipe 1 is connected to the sliding inner shaft 5, the inner anchor pipe 7, and the inner anchor head 8 in sequence; the reference pipe 1 There is a protective tube 2 outside to prevent grouting and grouting; the lower end of the protective tube 2 is connected to the sliding jacket 3; the lower part of the sliding jacket 3 is embedded with an elastic rubber plug 6; the elastic rubber plug 6 is set on the reference pipe 1. The lower sliding inner shaft 5 is embedded and pressed in the shaft shoulder disc; an elastic rubber plug 6 and an O-ring 4 between the sliding outer sleeve and the sliding inner shaft 5 are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com